Lifting device and AGV with device

A lifting device, trolley technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of short lead screw life, complex lifting and rotating structure design, lead screw plus cam and multi-link jacking cost, etc. The effect of installation and debugging difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

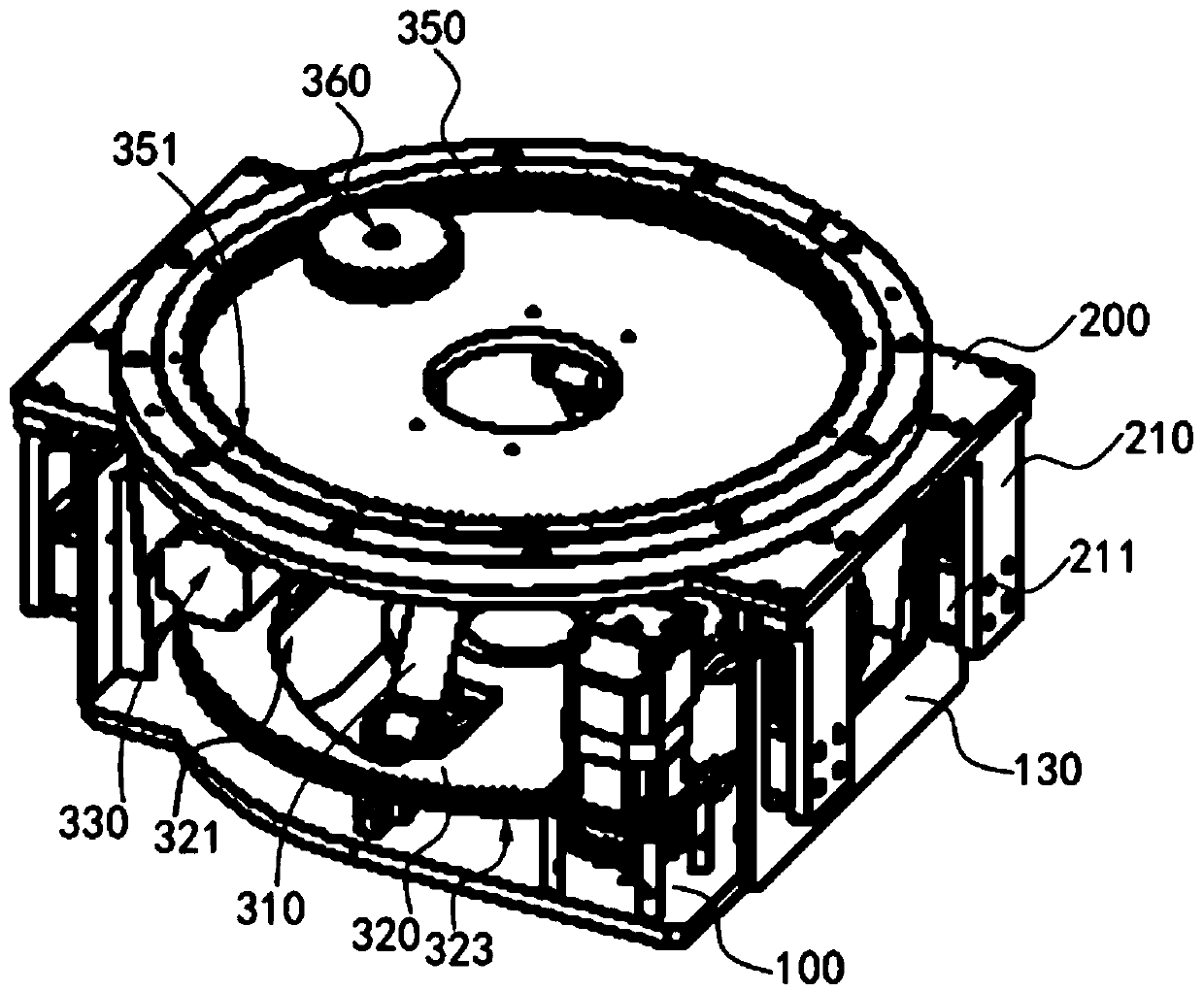

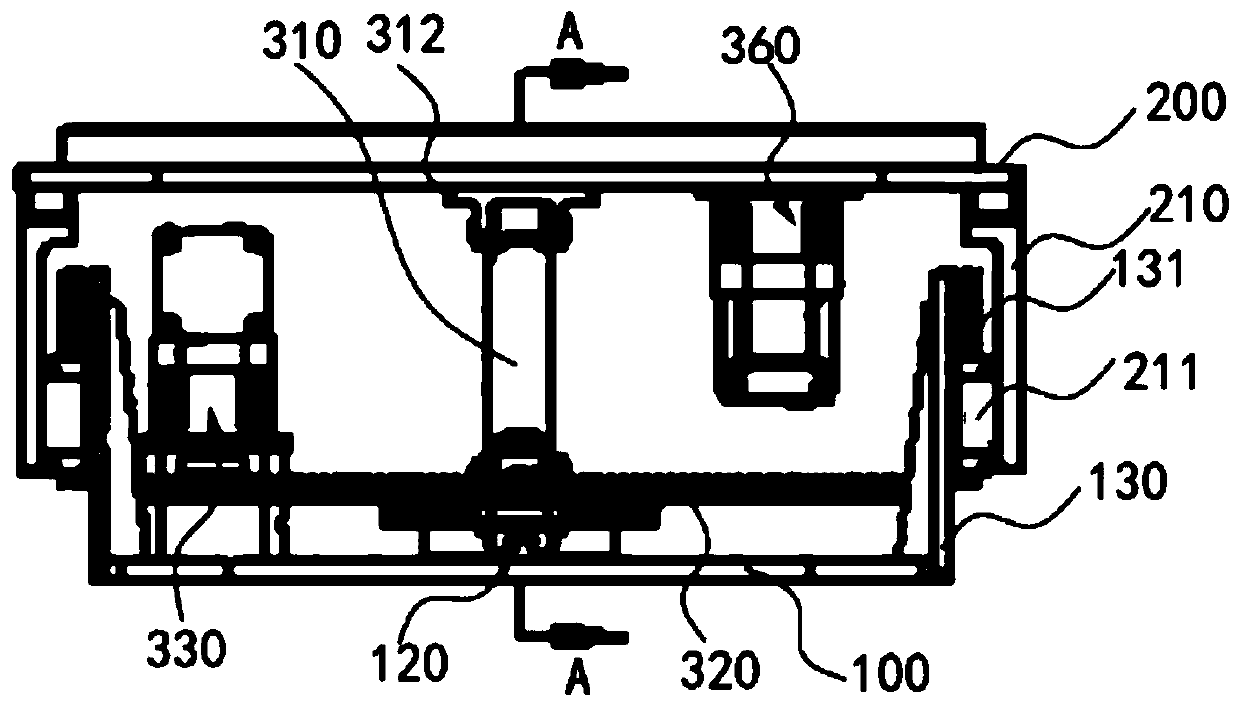

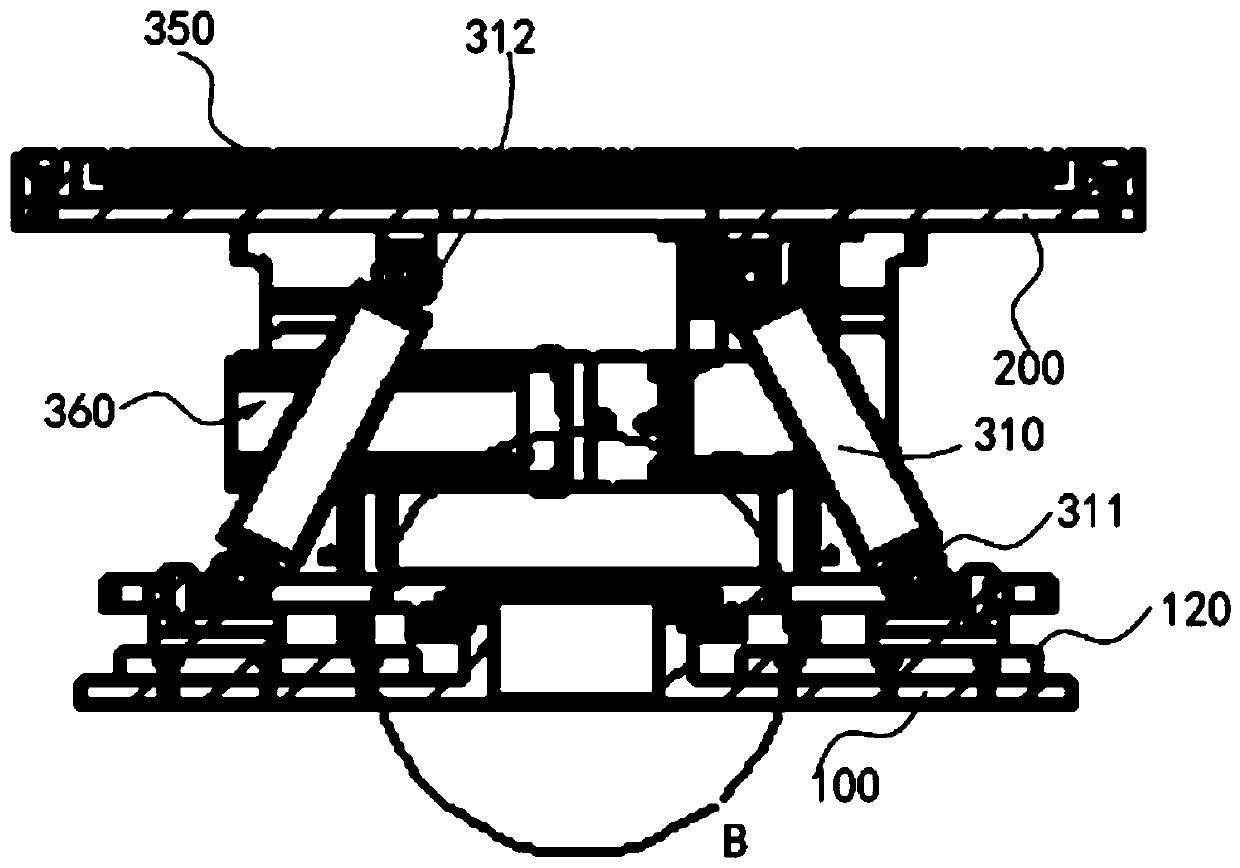

[0078] refer to figure 1 , which typically shows a perspective view when the lifting device proposed in the present disclosure is installed on an AGV trolley. In this exemplary embodiment, the lifting device proposed in the present disclosure is described as being applied to an AGV trolley as an example. Those skilled in the art can easily understand that in order to apply the relevant design of the present disclosure to other types of running gear or transportation equipment, various modifications, additions, substitutions, deletions or other modifications are made to the following specific embodiments variations, which remain within the scope of the principles of the lift proposed by the present disclosure.

[0079] Such as figure 1 As shown, in this embodiment, the lifting device proposed by the present disclosure can be installed between the fixed module and the lifting module, so that the lifting module can be arranged on the fixed module in a liftable manner. Wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com