A Method for Determining the Inclination Angle of Each Circle of Fresnel Heliostat

The technology of heliostat and circle is applied in the field of solar energy utilization, which can solve the problems of poor condensing effect of flat mirror, difficulty in adjusting sub-mirrors, high cost, etc., so as to reduce the difficulty of installation and debugging, and realize the effect of condensing and good condensing light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

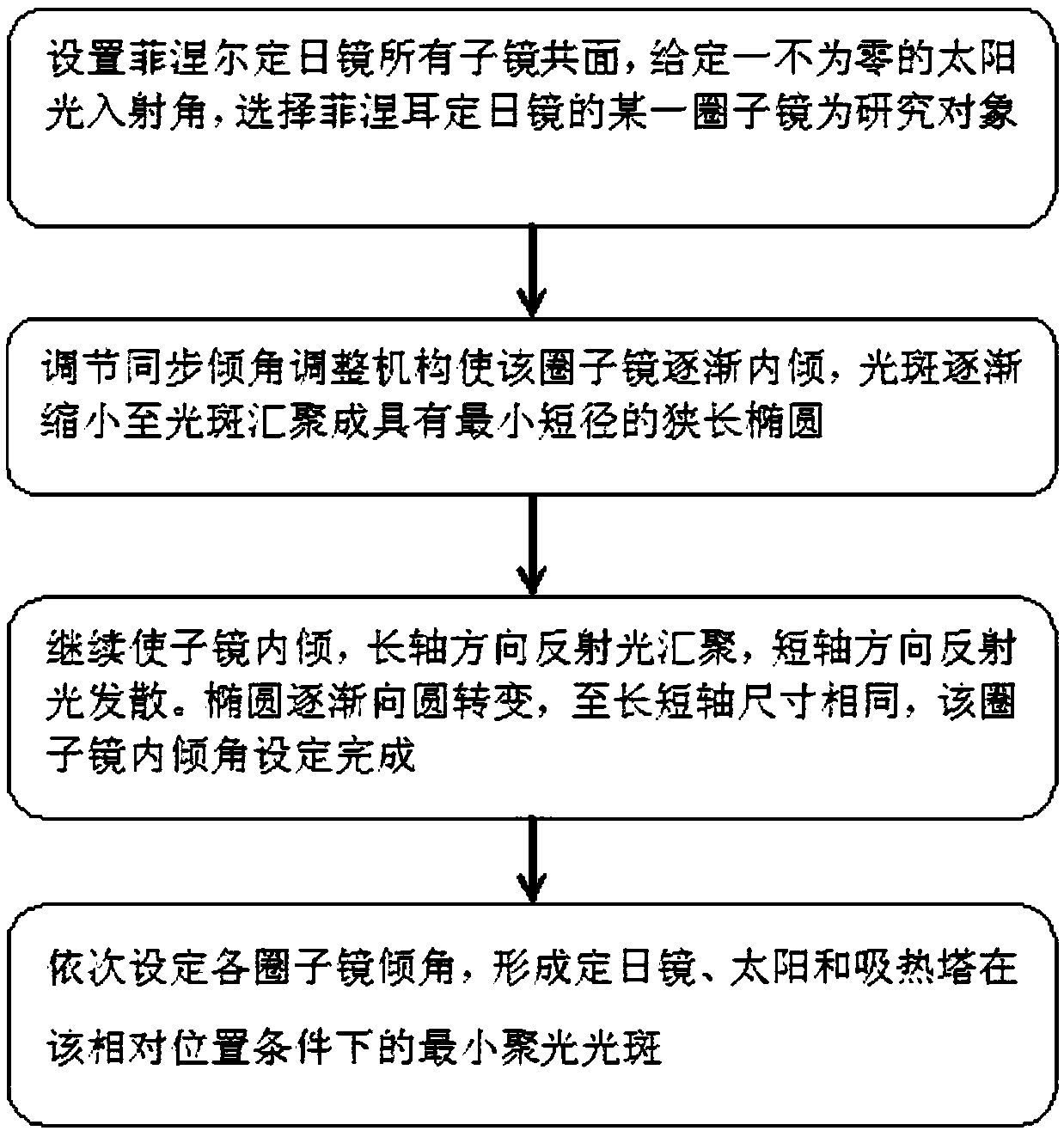

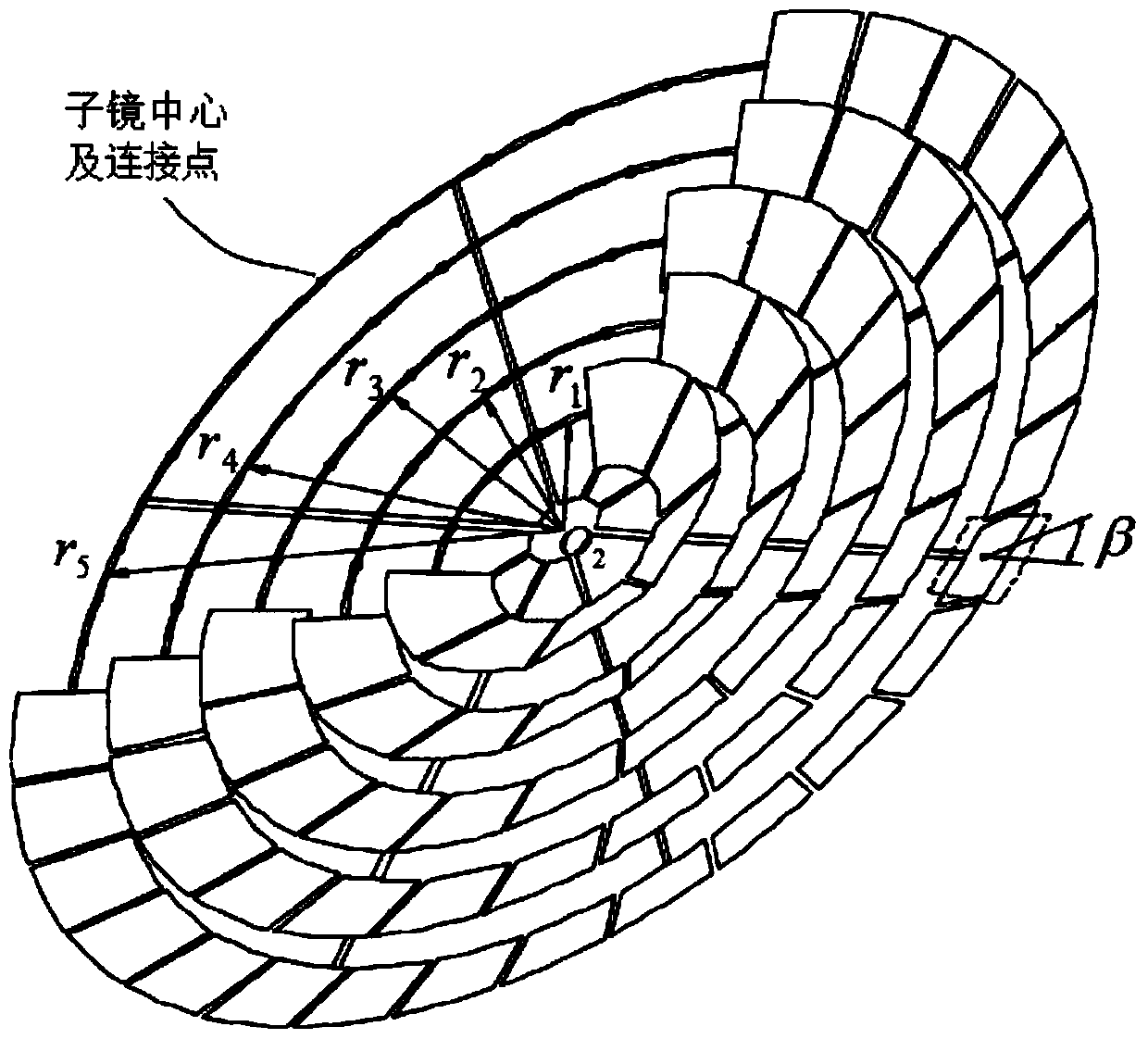

[0029] Such as figure 1 and 3 As shown, a method for determining the inclination angle of each circle of a Fresnel heliostat includes the following steps:

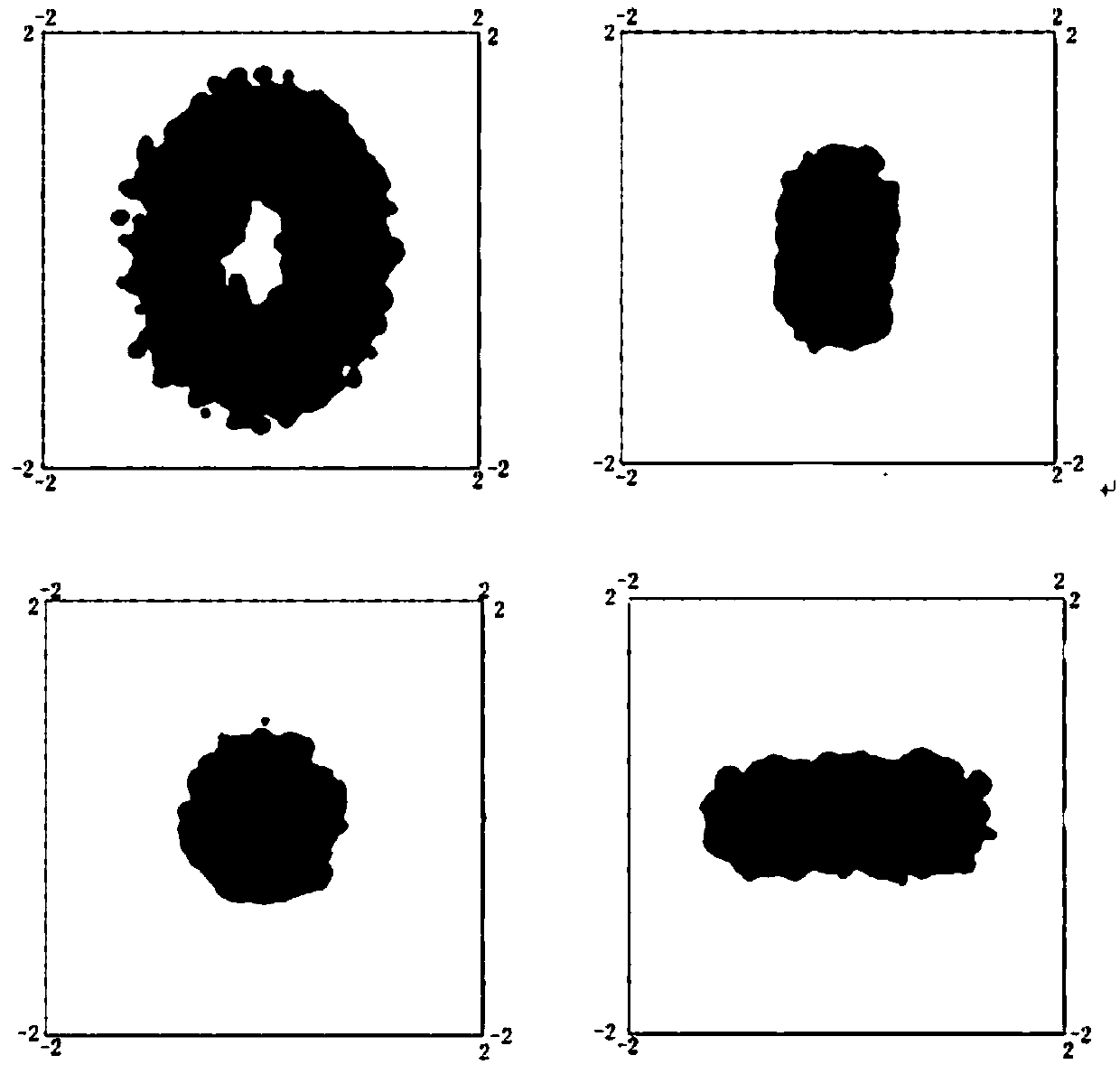

[0030] (1) Set all the sub-mirrors of the Fresnel heliostat to be coplanar, and given a non-zero incident angle of sunlight, select a certain circle mirror of the Fresnel heliostat, the circle mirror is in the absorption tower The spot on the hot surface is a larger hollow ellipse;

[0031] (2) The circle mirror is gradually tilted inward through the synchronous inclination adjustment mechanism, so that the light spot gradually shrinks until the light spot converges into a long and narrow ellipse with the smallest minor axis, and the reflected light in the direction of the minor axis converges to the extreme;

[0032] (3) Continue to tilt the sub-mirror inward, the reflected light in the direction of the major axis continues to converge, the light in the direction of the minor axis begins to diverge, and the ellipse begi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com