Fresnel dish type condenser and attitude setting method thereof

A concentrating mirror and dish-type technology, applied in the field of solar energy utilization, can solve the problems of production, transportation and installation difficulties, high cost investment, high production cost, etc., and achieve the effect of reducing the difficulty of installation and commissioning, reducing the cost of installation and commissioning, and saving the man-hours of installation and commissioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

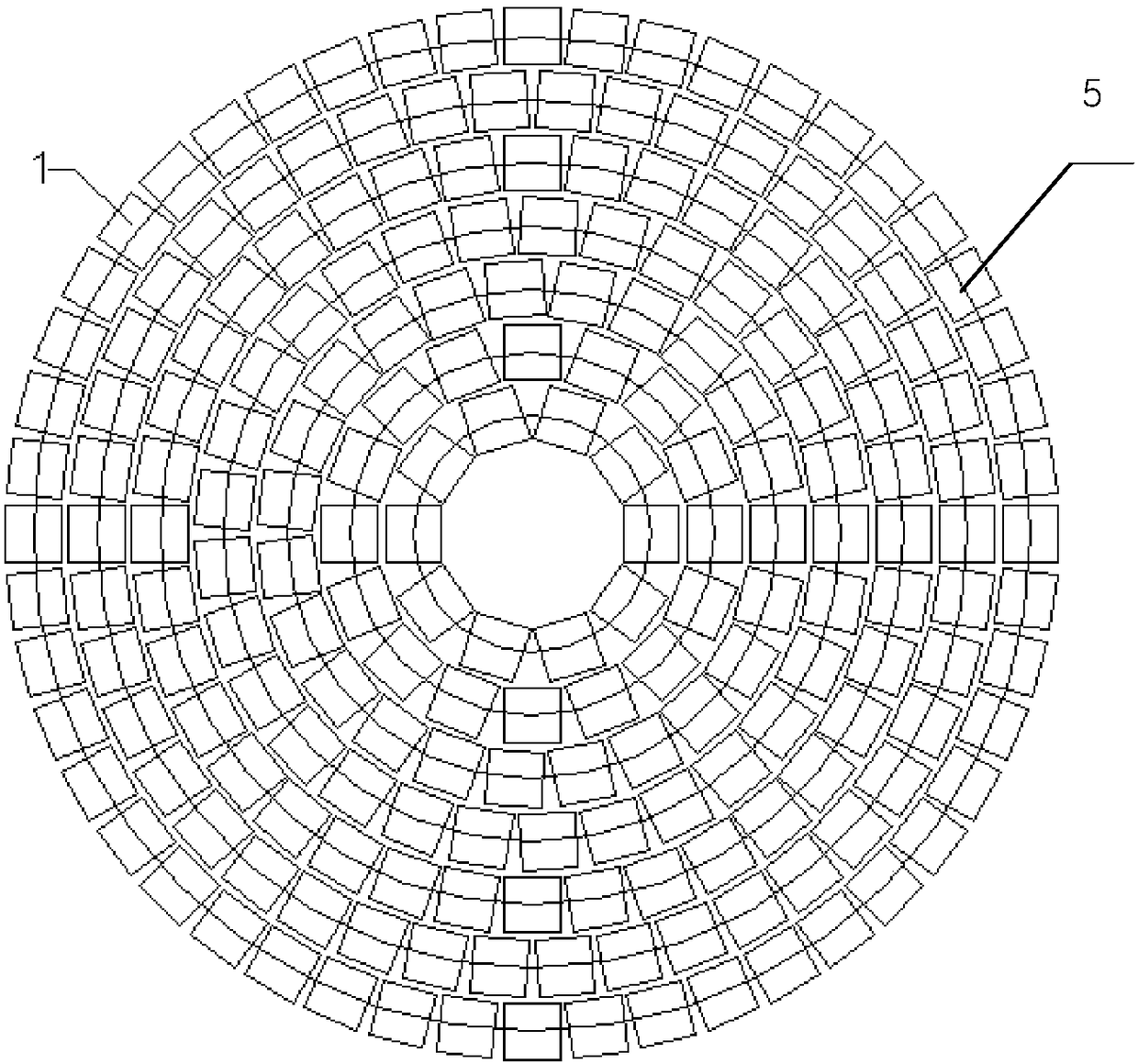

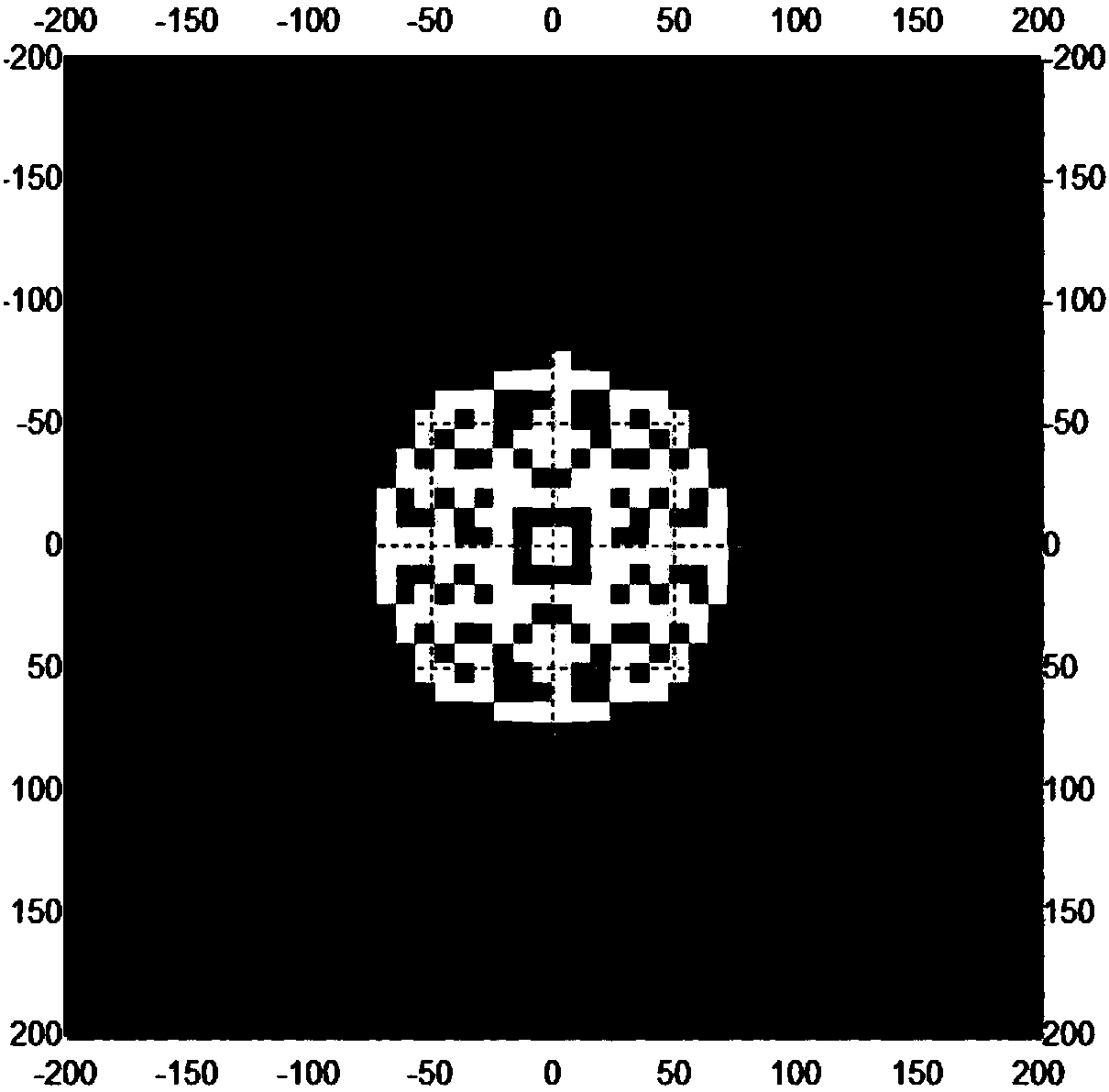

[0032] Such as figure 1 , the present embodiment discloses a Fresnel dish condenser, comprising a group of sub-mirrors 1, the group of sub-mirrors 1 is seven centrally symmetrical annular distribution circles, and there are more than three sub-mirrors in each circle, and the sub-mirrors are A flat mirror, and all sub-mirrors focus to one position. The specifications of the sub-mirrors are uniform, using 204 square sub-mirrors with a side length of 150mm, of which, there are 10 sub-mirrors in the first circle with a radius of 320mm, 16 sub-mirrors in the second circle with a radius of 490mm, and 23 sub-mirrors in the third circle There are 29 sub-mirrors in the fourth circle with a radius of 830mm, 36 sub-mirrors in the fifth circle with a radius of 1000mm, 42 sub-mirrors in the sixth circle with a radius of 1170mm, and 48 sub-mirrors in the seventh circle. The radius is 1340mm.

Embodiment 2

[0034] This embodiment is made up of a plurality of planar sub-mirrors 1, and the reflective surfaces of all sub-mirrors are all in the same plane in the initial state, and the sub-mirrors are surrounded by a plurality of concentric circles, arranged in a centrally symmetrical ring array, and the condenser mirror is composed of 7 circles of sub-mirrors. Composition, sub-mirror specifications are uniform, using 204 square sub-mirrors with a side length of 150mm, of which, the first circle has 10 sub-mirrors with a radius of 320mm, the second circle has 16 sub-mirrors with a radius of 490mm, and the third circle has a total of 23 sub-mirrors with a radius of 660mm, the fourth circle has 29 sub-mirrors with a radius of 830mm, the fifth circle has 36 sub-mirrors with a radius of 1000mm, the sixth circle has 42 sub-mirrors with a radius of 1170mm, and the seventh circle has 48 sub-mirrors mirror with a radius of 1340mm.

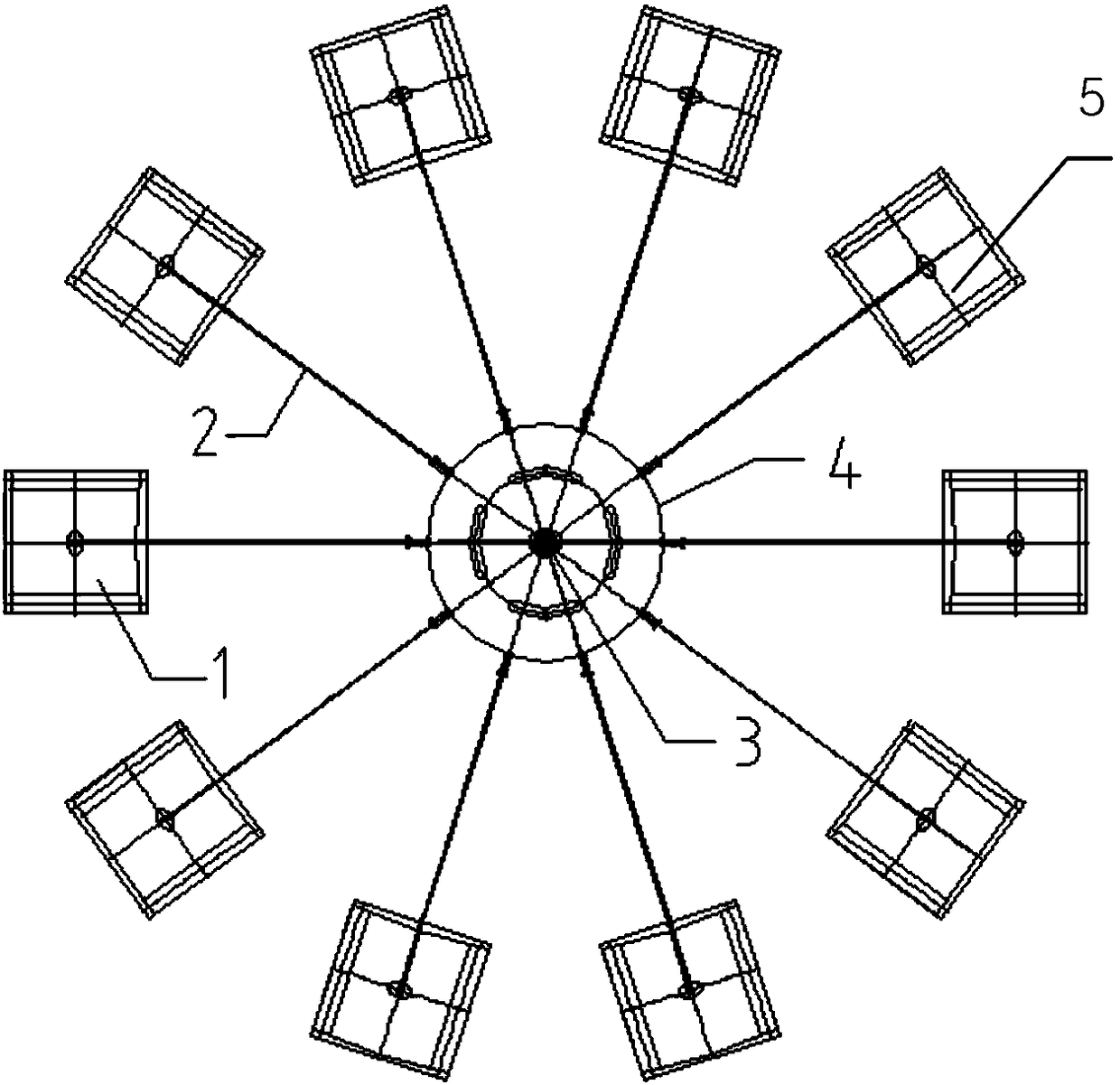

[0035] Such as figure 2 , the structural diagram of a circ...

Embodiment 3

[0040] In this embodiment, the shape of the sub-mirror 1 is fan-shaped, and each circle of sub-mirrors is also arranged in a centrally symmetrical annular array. unanimous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com