Two-shaft vibration test device with integrated base

A test device and shaft vibration technology, which is applied in vibration testing, measuring devices, testing of machines/structural components, etc., can solve the problems of cumbersome installation, vibration interference, and high installation accuracy requirements, so as to reduce the overall height, avoid dryness, The effect of ensuring test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

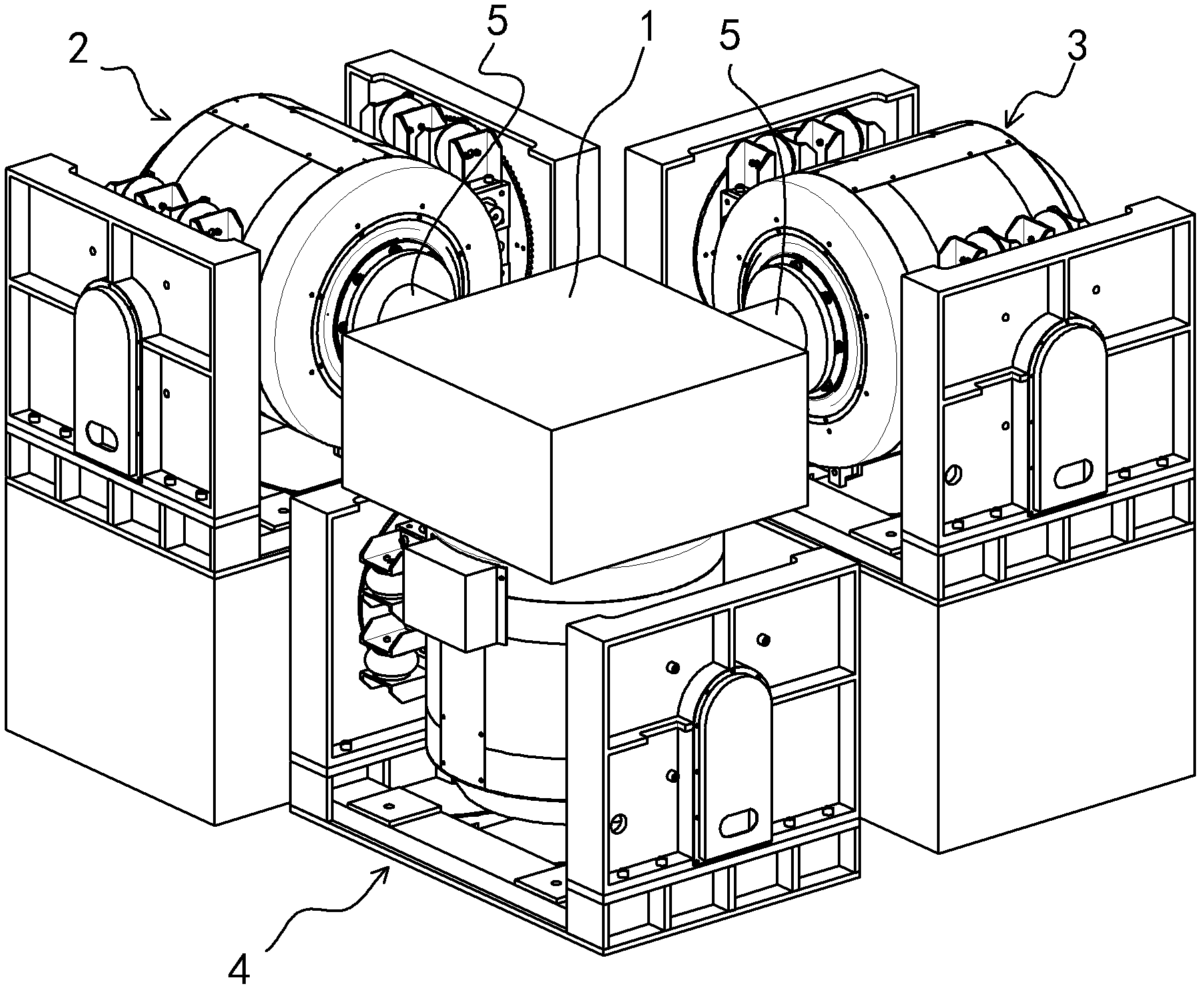

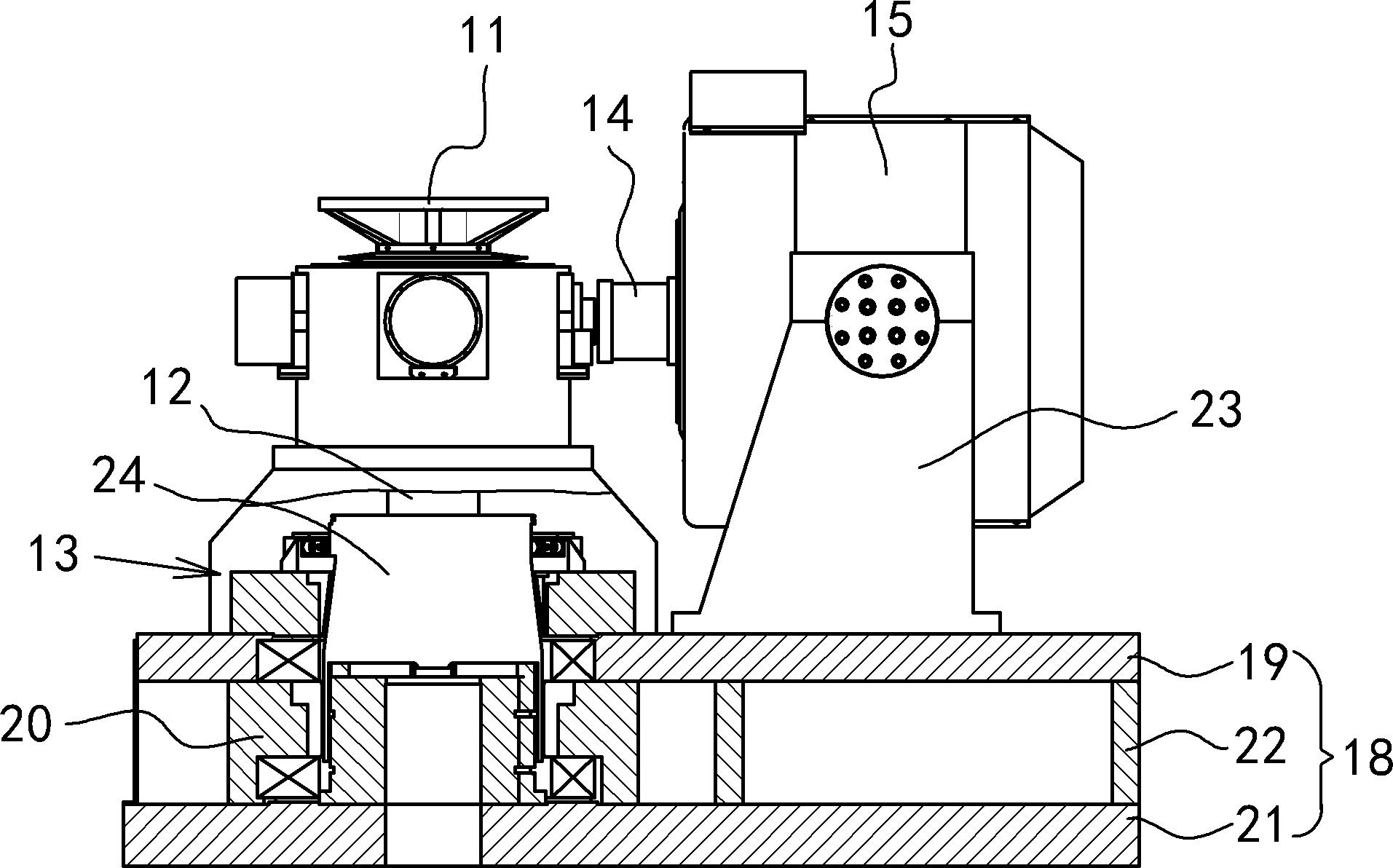

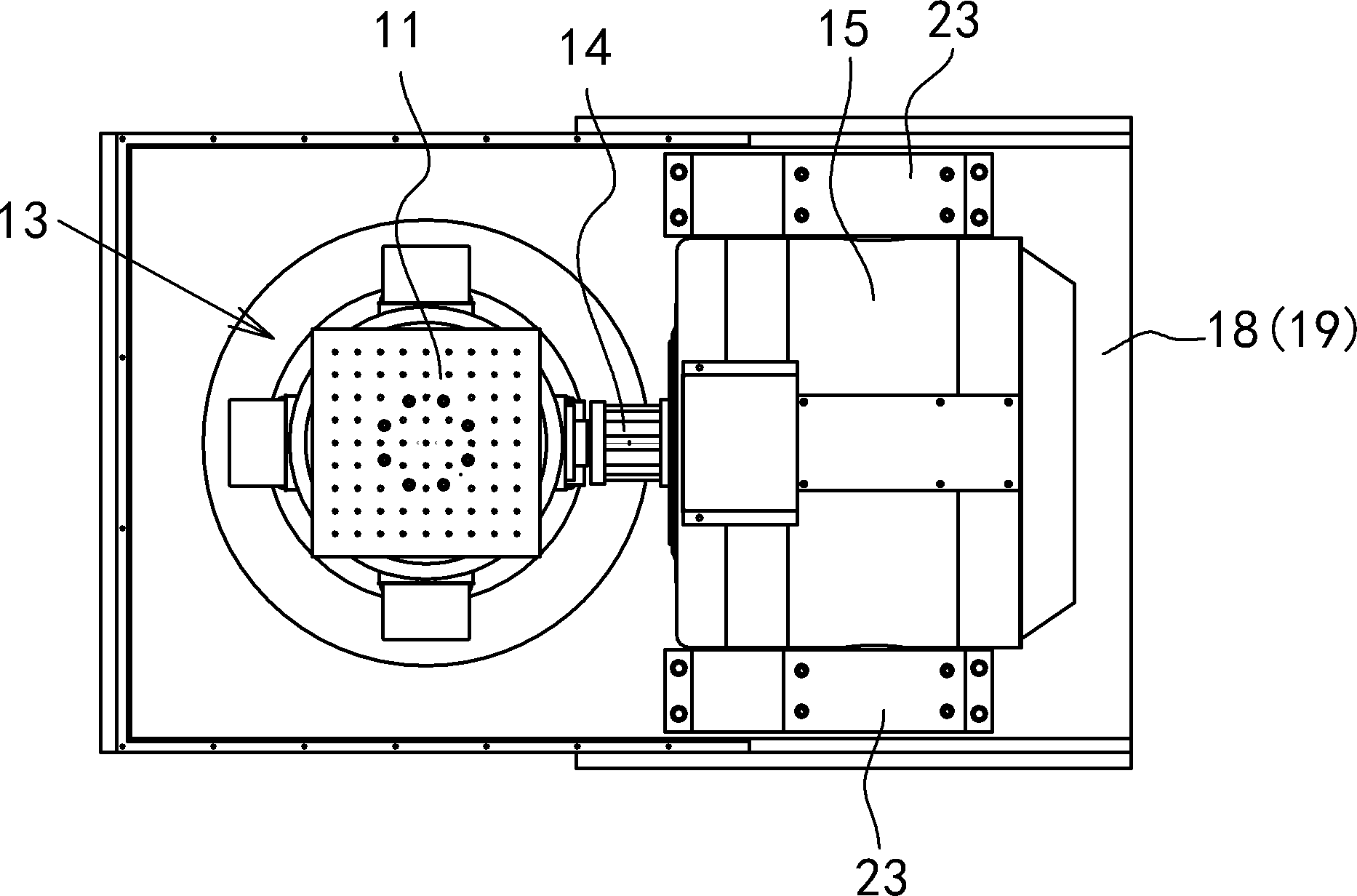

[0026] Embodiment one: see appendix figure 2 , attached image 3 Shown:

[0027] A two-axis vibration test device with an integrated base, which has a working table 11, and the working table 11 is connected to a vertical electric vibration table 13 through a first vibration transmission decoupling mechanism 12 in the vertical direction (that is, the Z axis) The moving coil table top is connected to the moving coil table top of a horizontal electric vibrating table 15 via the second vibration transmission and decoupling mechanism 14 in the horizontal direction (that is, the X axis).

[0028] The magnetic cylinder parts in the table body of the vertical electric vibrating table 13 expand and extend in the horizontal direction to form a seat 18, the top surface of the seat 18 is used to carry the horizontal electric vibrating table 15, and the horizontal electric vibration The platform body of the platform 15 is fixedly disposed on the top surface of the base body 18 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com