A kind of pile foundation protection pile and construction method

A technology of pile foundation and pile pole, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of insufficient bearing capacity at the bottom of the pile, affecting the centering accuracy of the reinforcement cage, and poor stability of the pile body, etc. The probability of instability, the effect of strengthening the connection stability and the convenience of later removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

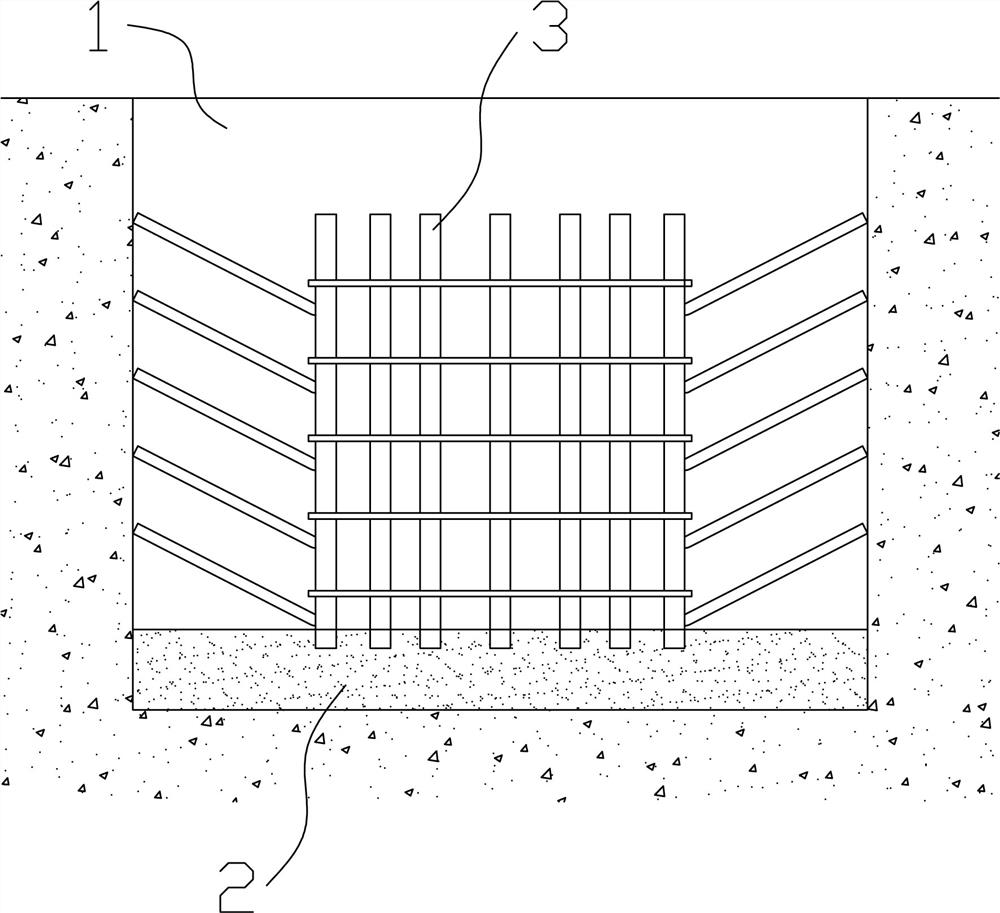

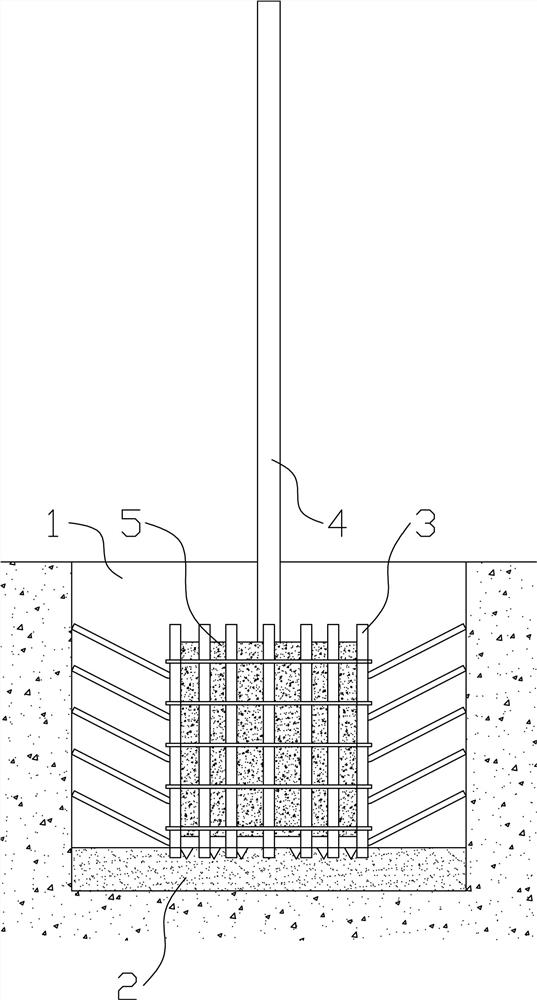

[0040] Such as Figure 1-3 Among them, a pile foundation protection pile, including pile protection pole 4 and concrete base 5, also includes reinforcement cage 3, reinforcement cage 3 adopts the rectangular body structure of opening at both ends, reinforcement cage 3 is buried vertically around the concrete foundation 5 In the pile protection pit 1, the concrete base 5 is arranged in the reinforcement cage 3;

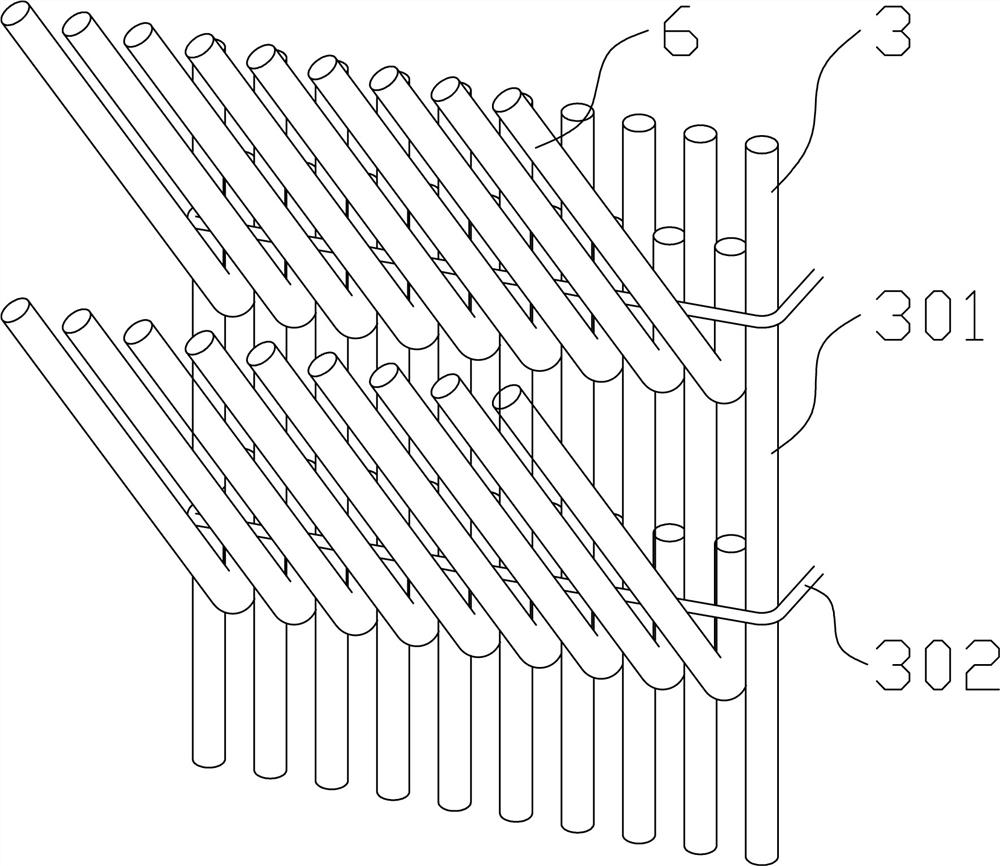

[0041] The reinforcement cage 3 is formed by binding the main reinforcement 301 and the stirrup 302 with wires, and a "V"-shaped reinforcement 6 is arranged between two adjacent main reinforcements 301, and one section of the "V"-shaped reinforcement 6 is bound with wires. It is fixed on the reinforcement cage 3, and the other section extends obliquely upwards to contact with the side wall of the pile protection pit 1.

[0042] In a preferred solution, the bottom surface of the pile protection pit 1 is backfilled with a sand layer 2 , and the lower end of the main rei...

Embodiment 2

[0046] On the basis of embodiment 1, adopt following construction method to carry out a kind of pile foundation pile protection construction:

[0047] 1) Use the special mold 8 to prefabricate the pile guard 4 and the concrete base 5;

[0048] 2) Prefabricated binding reinforcement cage 3;

[0049] 3) Excavation of pile protection pit 1 on site;

[0050] 4) Backfill fine sand on the bottom surface of the excavated pile protection pit 1 to form a sand layer 2;

[0051] 5) Install the reinforcement cage 3 to ensure that the main reinforcement 301 of the reinforcement cage 3 is inserted into the sand layer 2, and that the ends of the "V"-shaped reinforcement 6 on the periphery of the reinforcement cage 3 are in contact with the side wall of the pile protection pit 1;

[0052] 6) Install the concrete base 5 into the reinforcement cage 3, so that the reinforcement cage 3 and the concrete base 5 fit together;

[0053] 7) Backfill the soil and compact it.

Embodiment 3

[0055] Such as Figure 5-8 Among them, the special mold 8 is composed of a group of first side plates 9, a group of second side plates 10 and a bottom plate 11;

[0056] Both sides of the first side plate 9 are provided with vertical ribs 901, and both sides of the inner side of the second side plate 10 are provided with vertical grooves 1001 matching the vertical ribs 901;

[0057] Two parallel horizontal grooves 111 are provided on both sides of the top surface of the bottom plate 11, and the bottom of the second side plate 10 is provided with a horizontal convex strip 1002 matching the horizontal grooves 111;

[0058] The middle part of the bottom plate 11 is provided with an opening 112 having the same size as the support plate 7 .

[0059] In a preferred solution, the upper end of the vertical ridge 901 is flush with the top surface of the first side plate 9, the lower end of the vertical ridge 901 is higher than the bottom surface of the first side plate 9, and the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com