LED lamp strip convenient for replacement of LED lamp beads

A technology of LED light strips and LED light beads, which is applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., can solve problems such as personnel fatigue, potential safety hazards, and long distances for power switches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

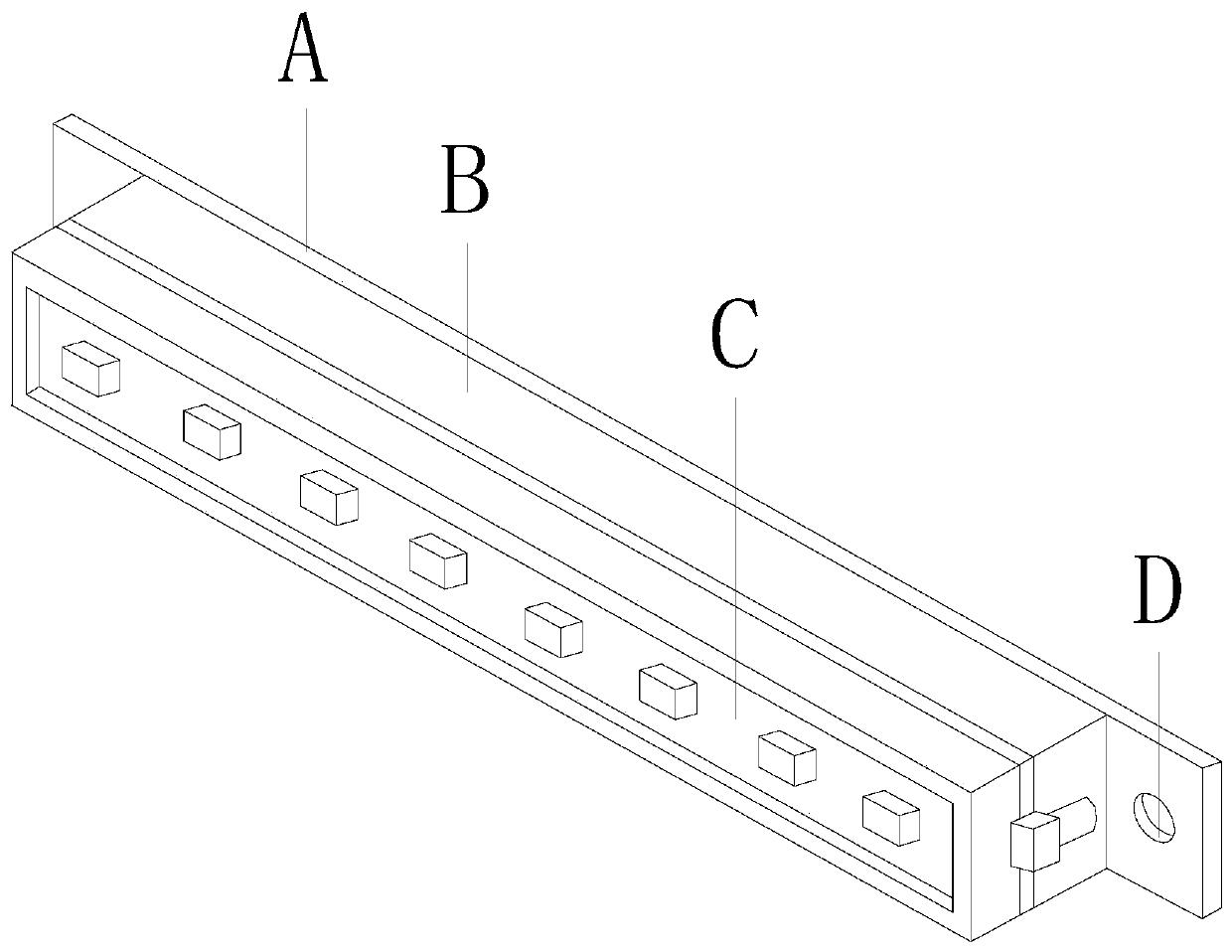

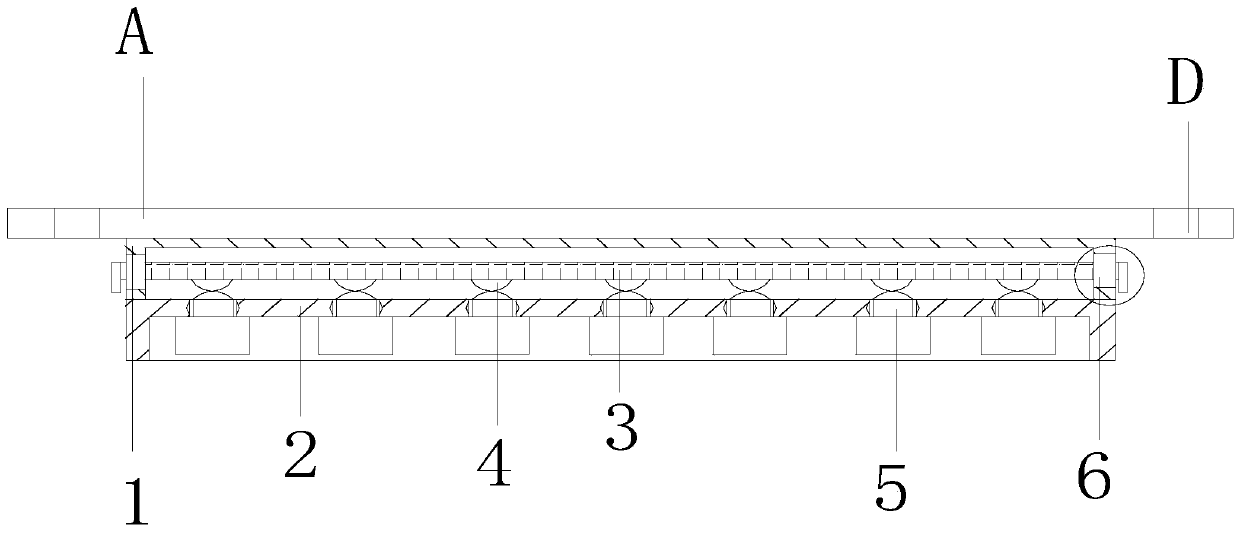

[0026] Such as Figure 1-Figure 4 Shown:

[0027] The present invention provides an LED light bar for easy replacement of LED lamp beads. Its structure includes a fixed plate A, a body B, a light bar mechanism C, and an auxiliary hole D. The fixed plate A is welded and connected to the bottom of the body B, and the auxiliary There are two holes D, and the auxiliary hole D is fixedly installed on both sides of the fixed plate A, characterized in that: the light bar mechanism C is embedded and connected inside the body B; the light bar mechanism C mainly includes a lower seat 1. Upper bearing 2, driving board 3, induction block 4, lamp bead device 5, sliding device 6, the upper bearing 2 is embedded and connected under the lower bearing 1, and the driving board 3 is movable through the sliding device 6 Closed in the middle of the lower seat 1, the induction block 4 is connected under the drive plate 3 with an interference fit, and the lamp bead device 5 is movably engaged and i...

Embodiment 2

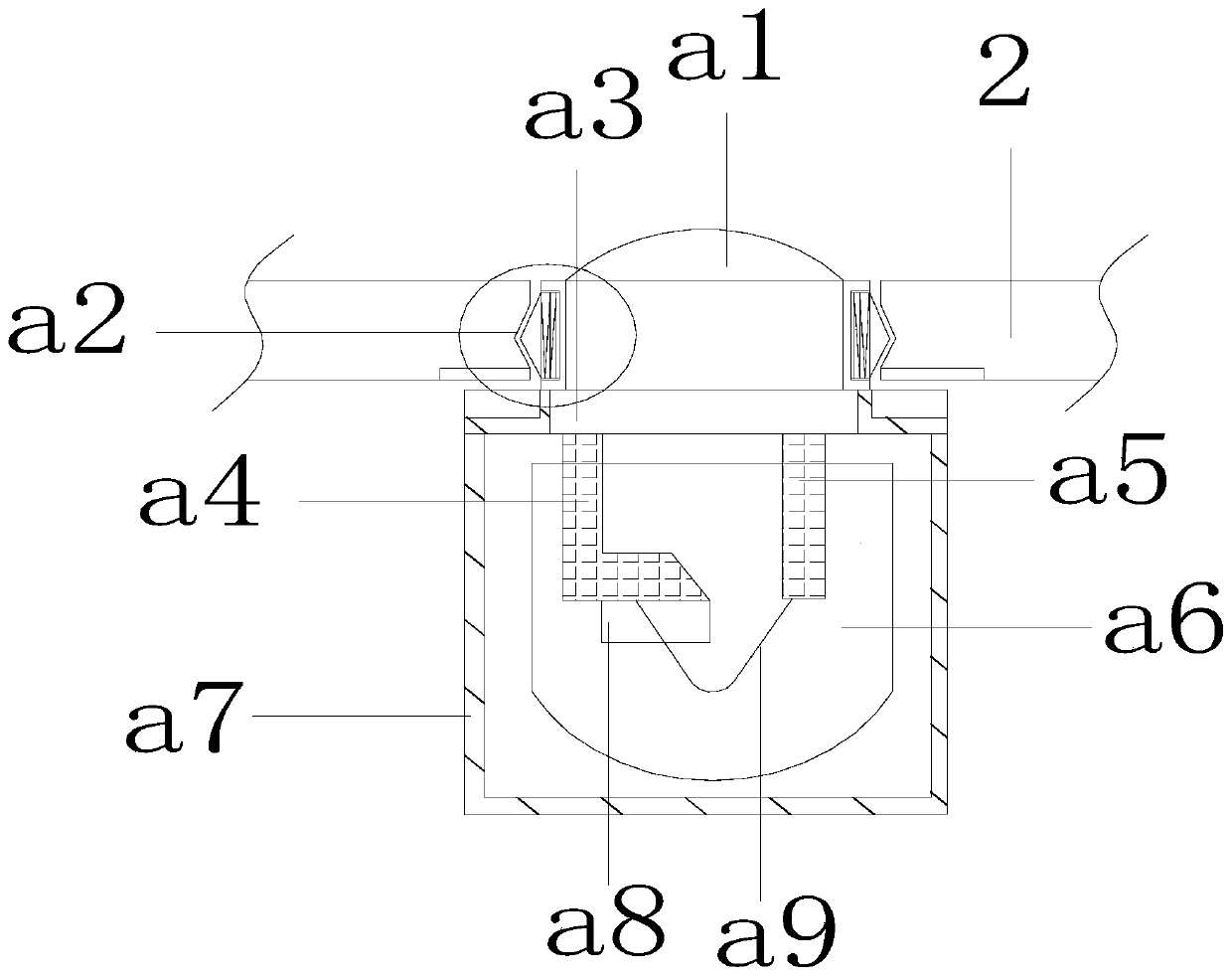

[0033] Such as Figure 5-Figure 8 Shown:

[0034] The present invention provides an LED light bar for easy replacement of LED lamp beads. The sliding device 6 mainly includes a fixed block 61, a moving groove column 62, and a push rod 63. The fixed block 61 is embedded and connected under the upper bearing 2. The moving slot column 62 is riveted and connected to the middle of the fixed block 61, and the push rod 63 is installed in the moving slot column 62 with clearance fit, and the push rod 63 is in interference connection with the drive plate 3. With the drive plate 3 in the middle as the midpoint, it has a left-right symmetrical structure, which conforms to ergonomics, and the simultaneous operation of both sides makes it easy to move.

[0035]Wherein, the moving groove column 62 mainly includes a connecting plate c1, an arc-shaped groove c2, and an auxiliary rolling c3, the connecting plate c1 is provided with an arc-shaped groove c2, and the auxiliary rolling c3 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com