Lens unit applied to main road working condition, lens assembly and streetlamp holder

A technology of lens units and working conditions, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., can solve the problem of insufficient research on light distribution requirements for double-sided installation, and the lighting effect cannot meet the desired requirements. , spherical lamps lack light distribution research and other problems, to achieve the effect of high light utilization, consistent direction, easy installation and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

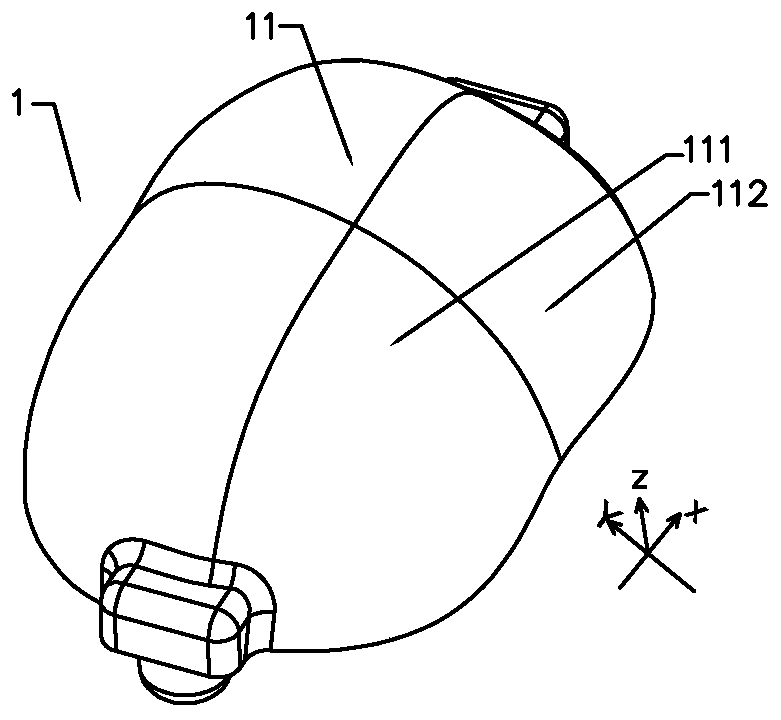

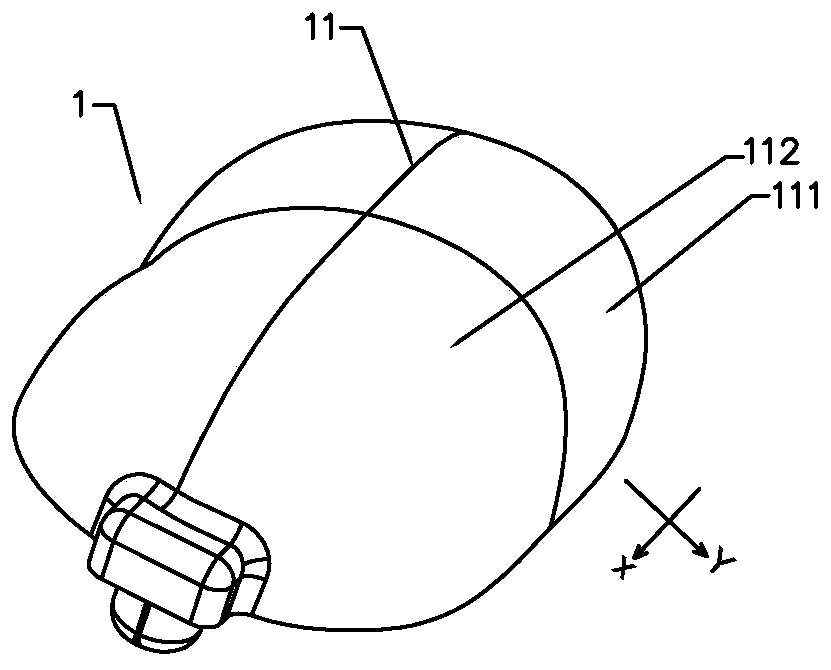

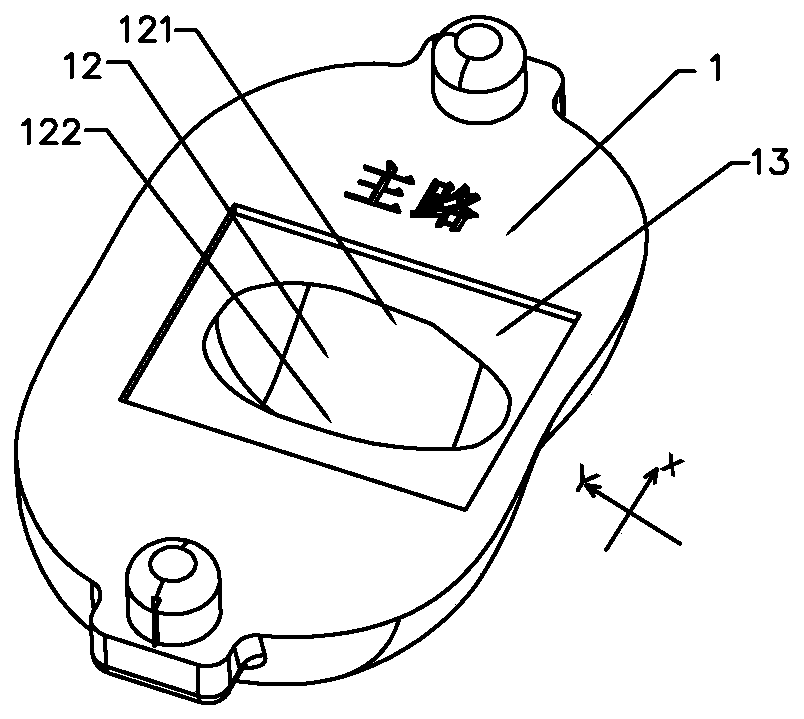

[0158] refer to Figure 12 , Figure 12 is a structural diagram of the first embodiment of the lens assembly. The lens assembly includes a substrate 15, a light-emitting device and a plurality of lens units 16 manufactured according to the above-mentioned embodiment of the lens unit. The substrate 15 is arranged in a ring shape, and multiple light-emitting devices are electrically connected to the substrate 15. Evenly distributed in the circumferential direction, the lens unit 16 is covered with the light-emitting device, so that the lens unit 16 is uniformly distributed in the circumferential direction, and the installation form of multiple lens units 16 is consistent (that is, when multiple lens units are installed, the positive direction of the minor axis faces consistent, and the positive direction of the major axis is in the same direction), that is, Figure 12 The settings shown; the installation form is consistent, which can make the direction of the light emitted by ...

no. 2 example

[0160] refer to Figure 13 , Figure 13 is a structural diagram of the second embodiment of the lens assembly. The lens assembly includes a substrate 17, a light-emitting device, and a plurality of lens units 18 made according to the above-mentioned embodiment of the lens unit. The substrate 17 is arranged in a strip shape, and four light-emitting devices are electrically connected to the substrate 17. The four light-emitting devices Distributed in sequence along the same direction, lens units 18 are arranged on the outer casing of the light-emitting device, so that the lens units 18 are arranged in sequence along the same direction, and multiple lens units 18 are installed in the same form, which can make the direction of the light emitted by the lens units consistent, that is, as Figure 10 settings shown. When the lens assembly is applied to a spherical lamp and the spherical lamp is applied to a main road, the short axis direction of the lens unit 18 corresponds to the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap