Simplified incremental iteration method for calculating ultimate strength of luxurious cruise ship

A technology of ultimate strength and incremental iteration, which is applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve problems such as not satisfying the flat section assumption, achieve short calculation operation time, stable and accurate calculation results, and high efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings.

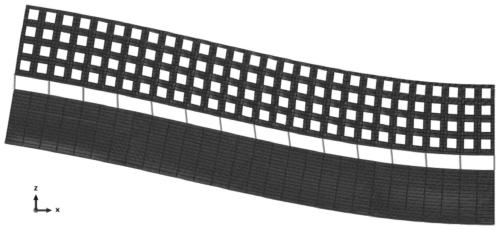

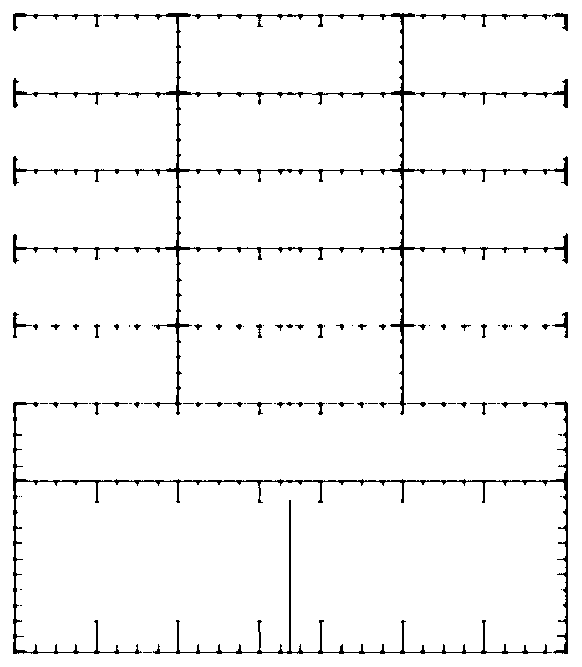

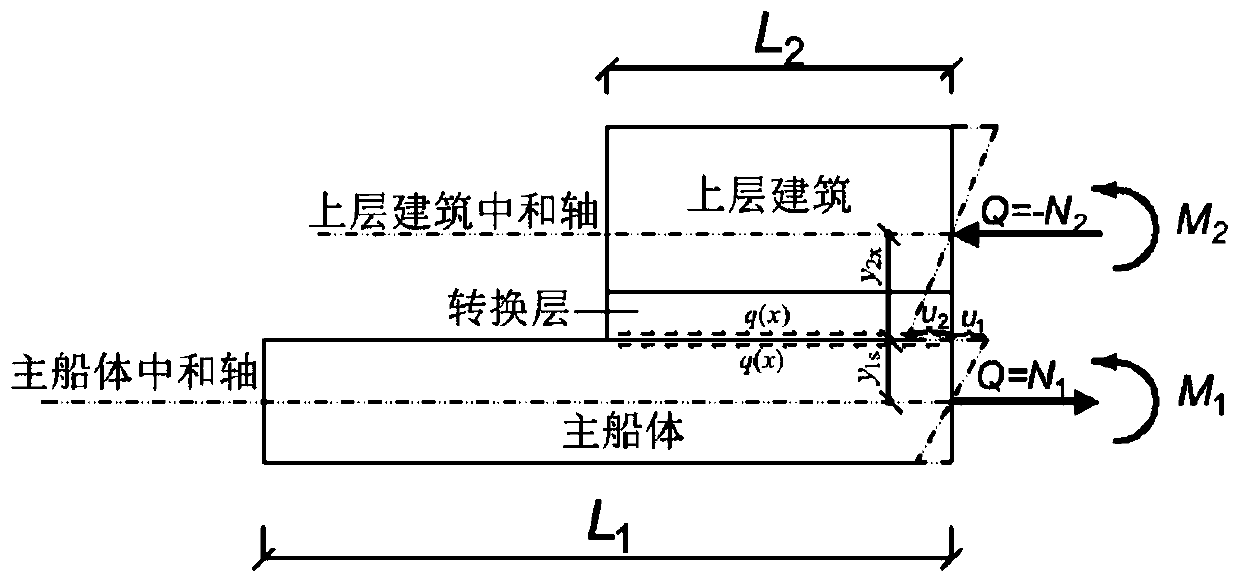

[0063] refer to Figure 1 to Figure 5 , a simplified incremental iterative method suitable for calculating the ultimate strength of a luxury cruise ship, by continuously increasing the curvature of the main hull and superstructure, when the average shear displacement of the transfer layer reaches the ultimate shear displacement, the hull girder cross-section The bending moment suffered above is regarded as the ultimate bending moment. On the basis of the Smith method, combined with the force and deformation characteristics of the passenger ship under the limit state, the deformation diagram of the side longitudinal wall from the stern to the midship in the sagging state is shown in the attached figure 1 (magnified by 60 times), the following assumptions are made: 1) The main hull and superstructure conform to the assumption of plane section during the bending process; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com