Method for determining content of azodicarbonamide in leather by HPLC (high performance liquid chromatography)

A technology of azodicarbonamide and high-performance liquid chromatography, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of no detection method, difficulty of detection, unusability, etc., and achieve good economic and social benefits, advanced Ease of handling and minimal matrix interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0029] 1. Determination of the content of azodicarbonamide blank solution in leather by high performance liquid chromatography

[0030] 1. Prepare a blank solution: take an appropriate amount of leather without azodicarbonyl, weigh it accurately, add 40mL of dimethyl sulfoxide, put it in a 50mL volumetric flask, extract it by ultrasonic for 30min, let it cool down, add dimethyl sulfoxide to volume , filtered with a 0.45µm filter membrane, which is a blank sample;

[0031] 2. Determination by high performance liquid chromatography:

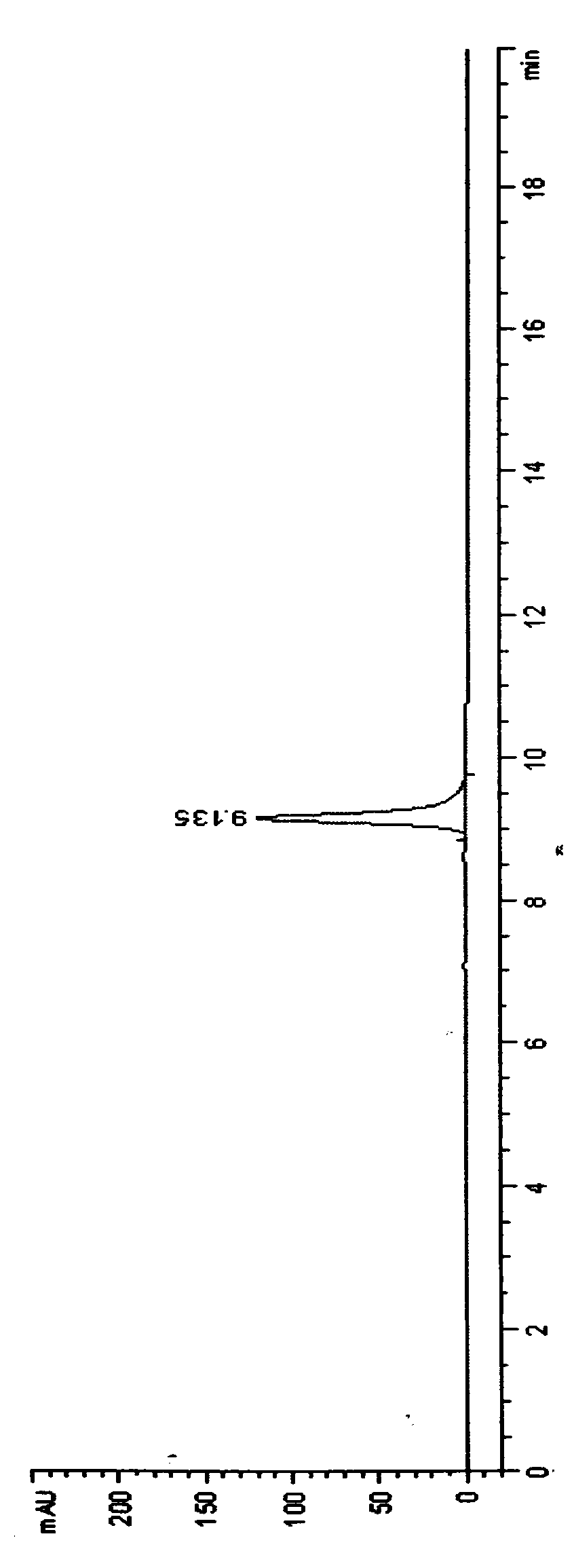

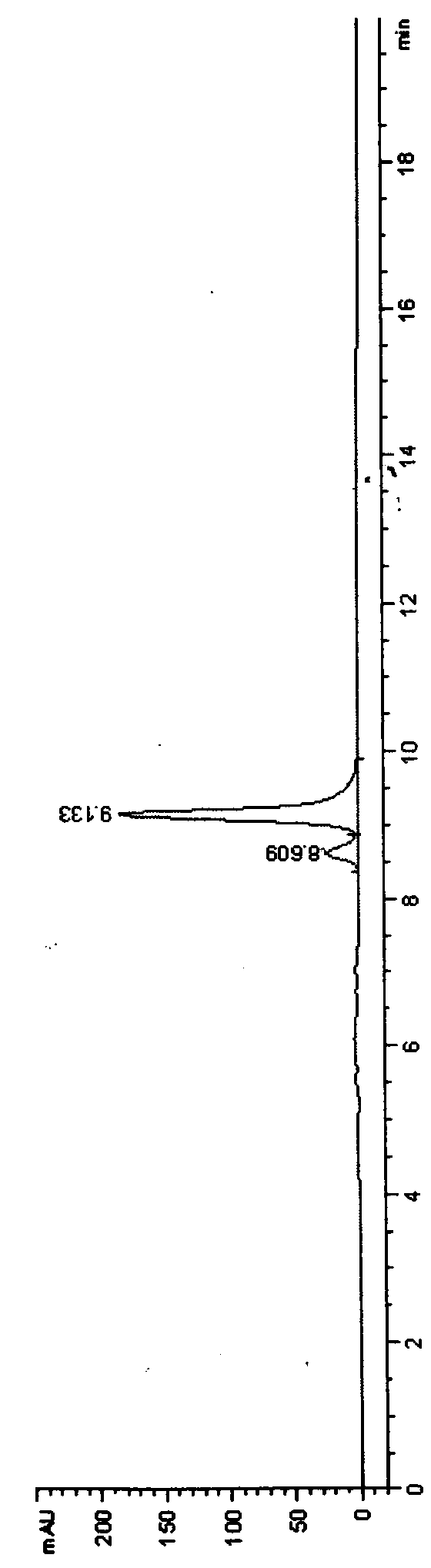

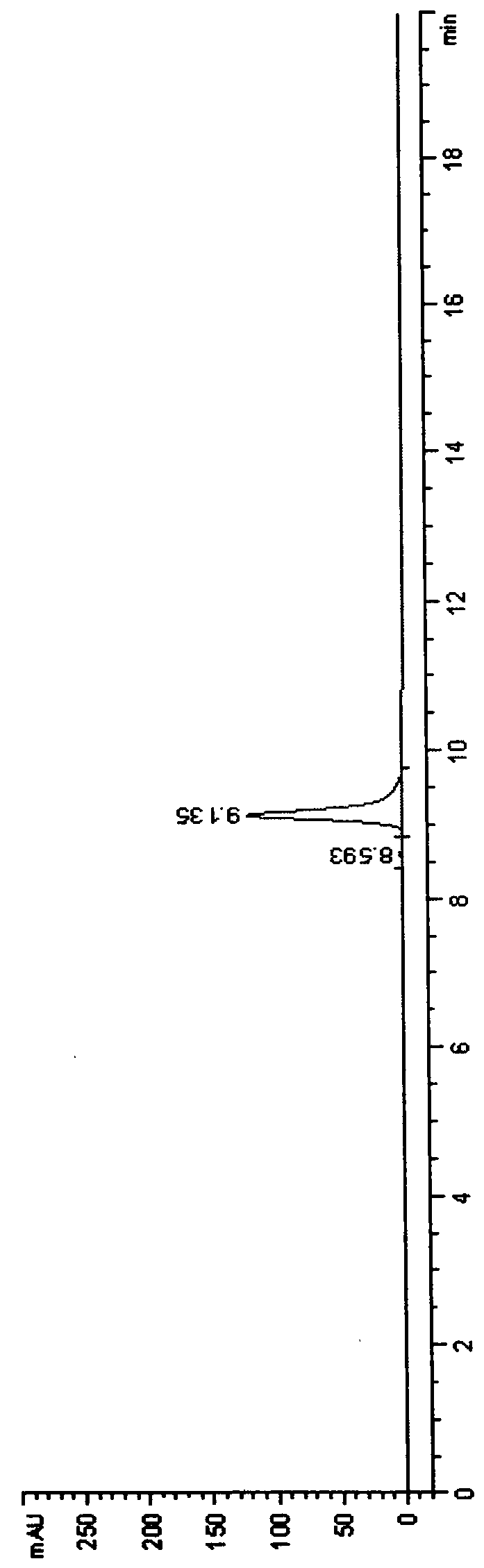

[0032] The above-mentioned blank sample was subjected to high-performance liquid chromatography determination, and the chromatographic conditions were: chromatographic column: hydrophilic column HILIC 250mm×4.6mm, 5µm; column temperature: 30°C; mobile phase: volume of acetonitrile: volume of water=60-70 : 40-30V / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com