Connecting part for connecting light wall body with steel framework, connecting structure and construction method

A light-weight wall and steel frame technology, applied to building structures, walls, building components, etc., can solve the problems of complex on-site construction, inconvenient installation, and insufficient firmness, and achieve convenient and quick installation, improve construction efficiency, and support good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

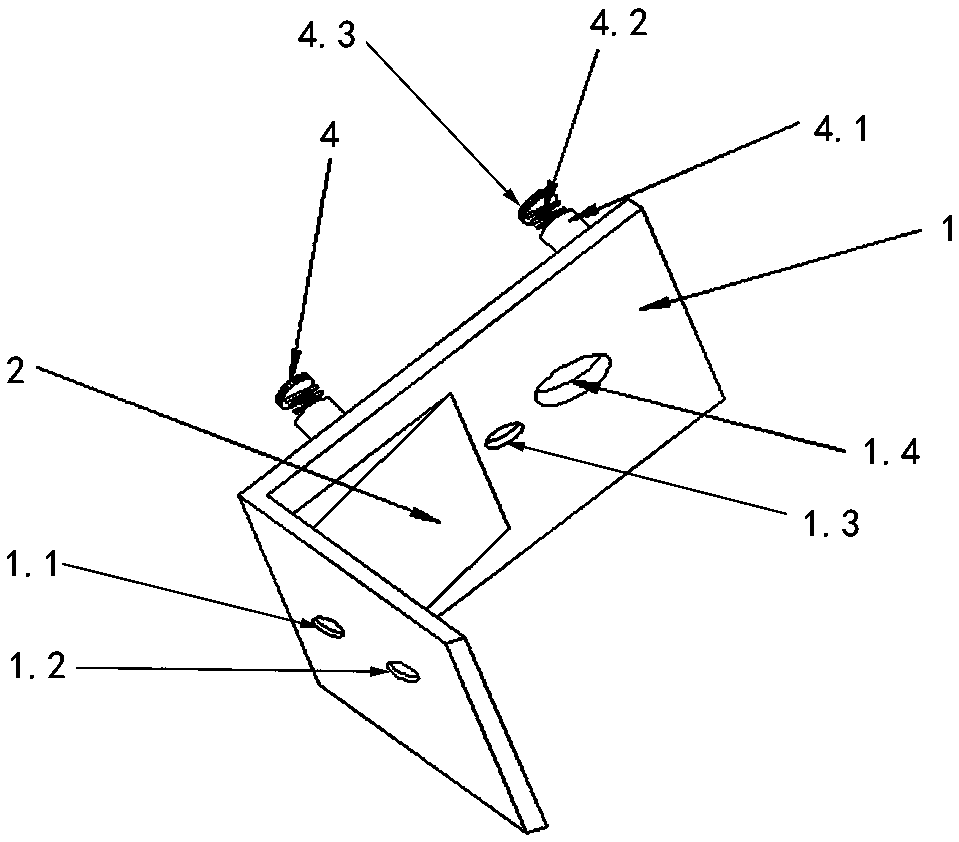

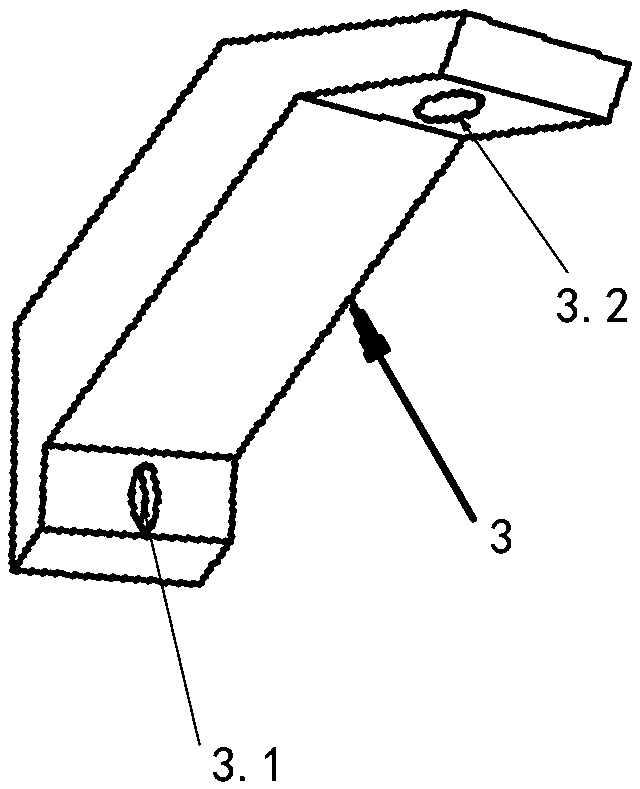

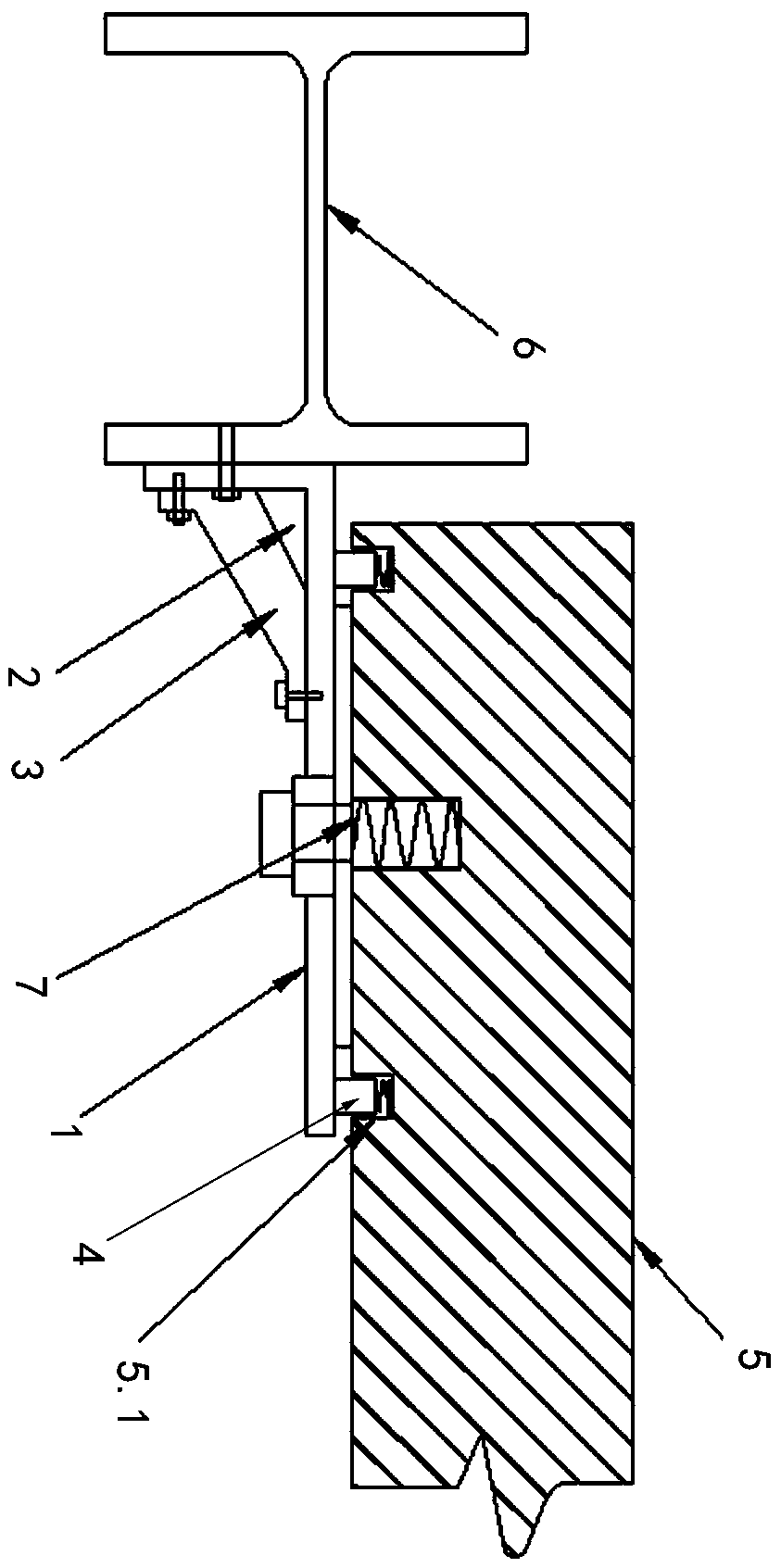

[0035] The connection piece, connection structure and construction method of the light wall body and the steel frame connection of the present invention, see figure 1 and figure 2 As shown, the connecting piece connecting the light wall and the steel frame includes an L-shaped connecting plate 1, a first support block 2 welded and connected to the inner corner of the L-shaped connecting plate 1, and detachably connected to the L-shaped connecting plate 1 The second support block 3 arranged on the outside of the first support block 2 , and the stopper 4 arranged at intervals and fixedly connected to the upper surface of the horizontal leg of the L-shaped connecting plate 1 .

[0036] The L-shaped connecting plate 1 is a plate body with an L-shaped cross section. The length of its horizontal limb is longer than that of the vertical limb, and it is an integrally formed alloy material; The first fixing hole 1.1 is used to connect the L-shaped connecting plate 1 with the steel be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com