Paper penetration rate measuring device and method

A technology of penetration rate and measuring device, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc. It can solve the problems that the penetration rate of the tested paper cannot be reflected, and achieve error reduction, good repeatability, The effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

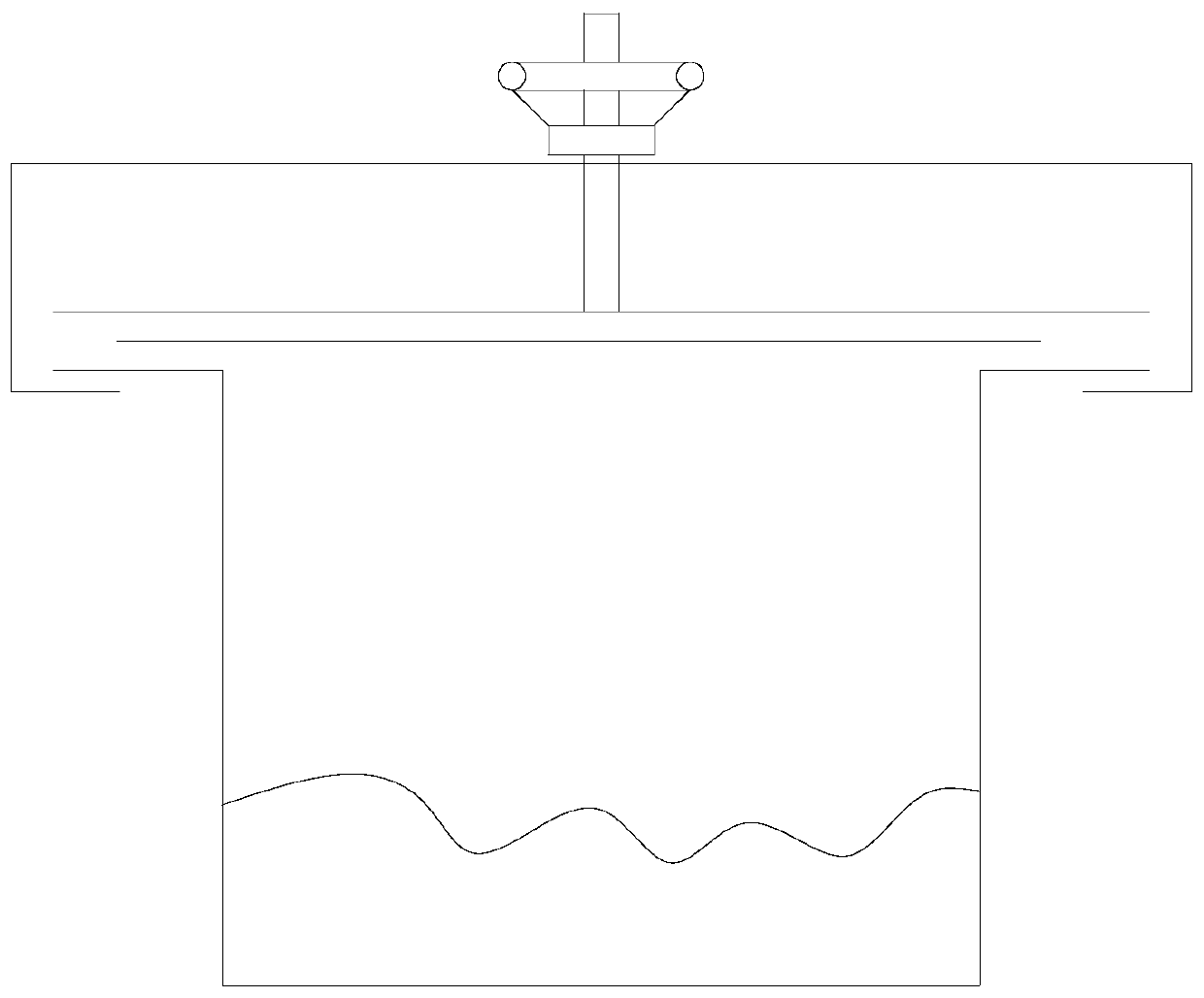

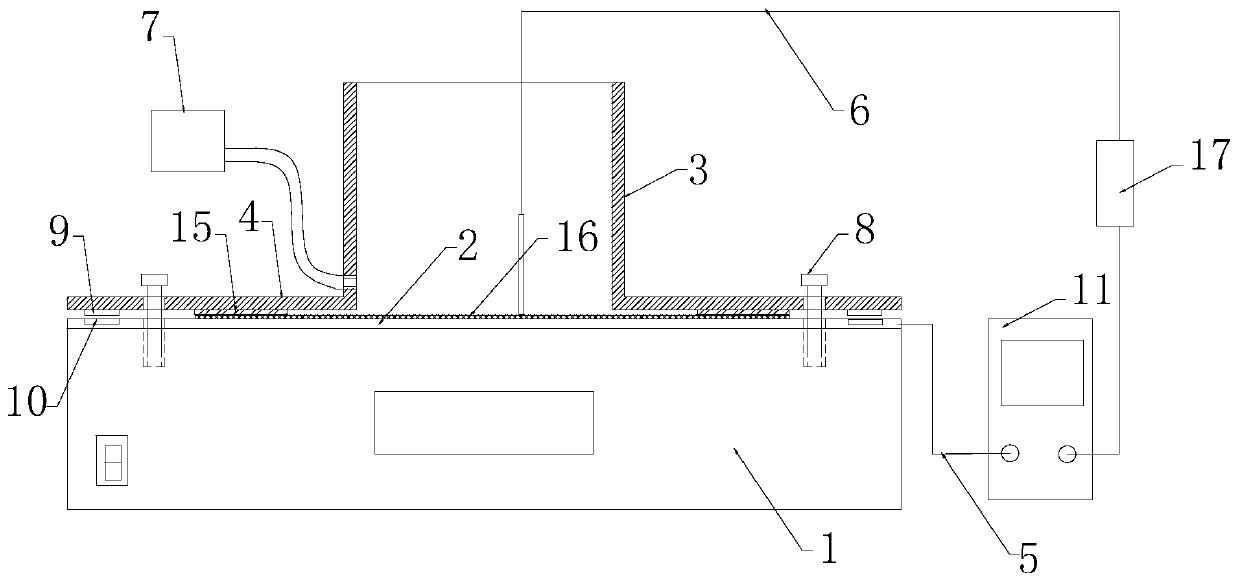

[0084] Such as figure 2 , 4 As shown, a paper penetration rate measuring device described in this embodiment is a device for measuring the water penetration rate of paper, including: a base 1, a rectangular flat conductive plate 2, an insulating cylinder 3, and an insulating pressing plate 4 , a locking part, a sealing ring 15, a power supply 17, a first conductor 5, a second conductor 6, an injection pump 7, a current sensor 11, a control module, a display module, and a timing module.

[0085] Wherein, the conductive plate 2 is arranged on the base 1, and the conductive plate is a copper plate; the insulating cylinder 3 is a cuboid cylindrical structure with open top and bottom ends, and the side wall of the insulating cylinder 3 is provided with a liquid injection port. The port is connected to the liquid injection pump through a pipeline; the insulating pressing plate 4 is a square ring, surrounds the outer side of the insulating cylinder, and is connected with the bottom...

Embodiment 2

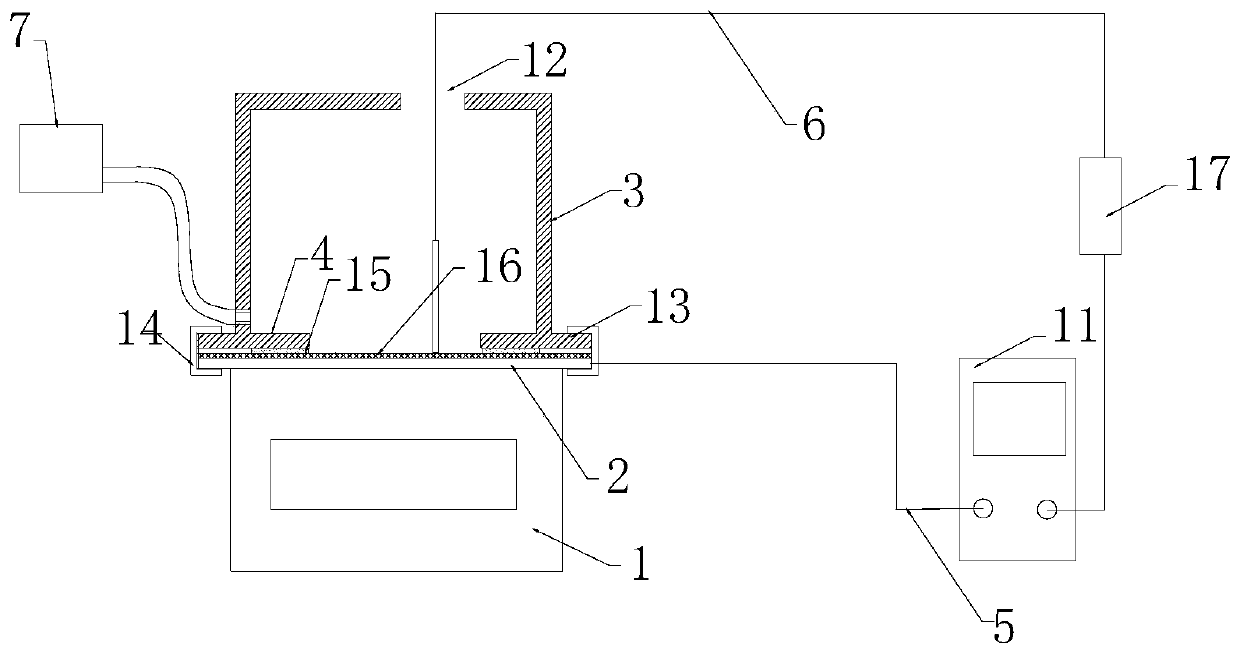

[0088] Such as image 3 , 4 As shown, a paper penetration rate measuring device described in this embodiment is a device for measuring the penetration rate of paper conductive ink, including: a base 1, a conductive plate 2, an insulating cylinder 3, an insulating pressing plate 4, and a sealing ring 15. Power supply, first conductor 5, second conductor 6, liquid injection pump 7, current sensor 11, control module, display module, timing module.

[0089] Wherein, the conductive plate 2 is arranged on the base 1, and the conductive plate is a copper plate, circular, and flat-shaped; the insulating cylinder 3 is a glass cylindrical structure with an open bottom, and a There is a test port 12 for the electrode column to pass through. The bottom end of the insulating cylinder is provided with a circle of outer edge 13. The insulating pressing plate 4 is circular and is arranged on the inner side of the insulating cylinder. The annular outer edge of the insulating pressing plate I...

Embodiment 3

[0092] A kind of paper permeation rate measuring method described in the present embodiment comprises:

[0093] S1. Lay the tested paper on the conductive plate, and set an insulating cylinder on the tested paper. The bottom of the insulating cylinder is open, and the tested paper closes the bottom of the insulating cylinder. Equipped with a detection port and a liquid injection port;

[0094] S2. Connect one pole of the power supply to the conductive plate through the first conductor, connect one end of the second conductor to the other pole of the power supply, and connect the other end of the second conductor to the wall surrounded by the insulating cylinder and the paper to be tested. The measured paper contact in the space;

[0095] S3. Inject water into the space surrounded by the insulating cylinder and the paper to be tested, start timing at the same time, and detect the current in the first conductor or the second conductor through the current sensor;

[0096] S4. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com