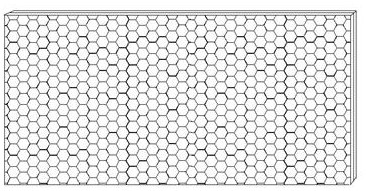

Flat infrared detection lens

An infrared detection and planar technology, applied in prisms, instruments, optics, etc., can solve problems such as narrow receiving surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

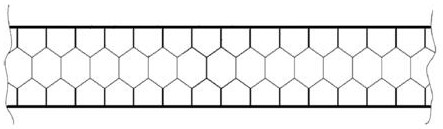

[0020] This embodiment improves the bottom surface on the basis of the above-mentioned embodiment. The improvement is that, firstly, the plate material has been positioned in the design stage, and secondly, according to the preset size, the receiving layer is Printing, the parts corresponding to the bottom surface are printed and colored; then the side walls are formed by stamping. When forming the side walls, it is required that the side walls do not need to be stretched. The method is to use the bottom heating method, that is, press After the die was in contact with the sheet for three seconds, a strong pressure was applied, whereby the bottom surface was stretched, while the thickness of the side wall was not changed. After the side wall is formed, the stamping head is changed, and the cold stamping method is still used at this time, so that the bottom surface is deformed, thereby forming the receiving layer. From the picture, I can see that after passing through the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com