Automatic battery replacing device and using method thereof

A technology for replacing batteries and batteries, which is applied in terminal battery switching devices, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of uncontrollable safety risks of manual battery replacement, large labor consumption, disassembly, and handling difficulties, etc. Achieve timely power supply, improve safety, save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

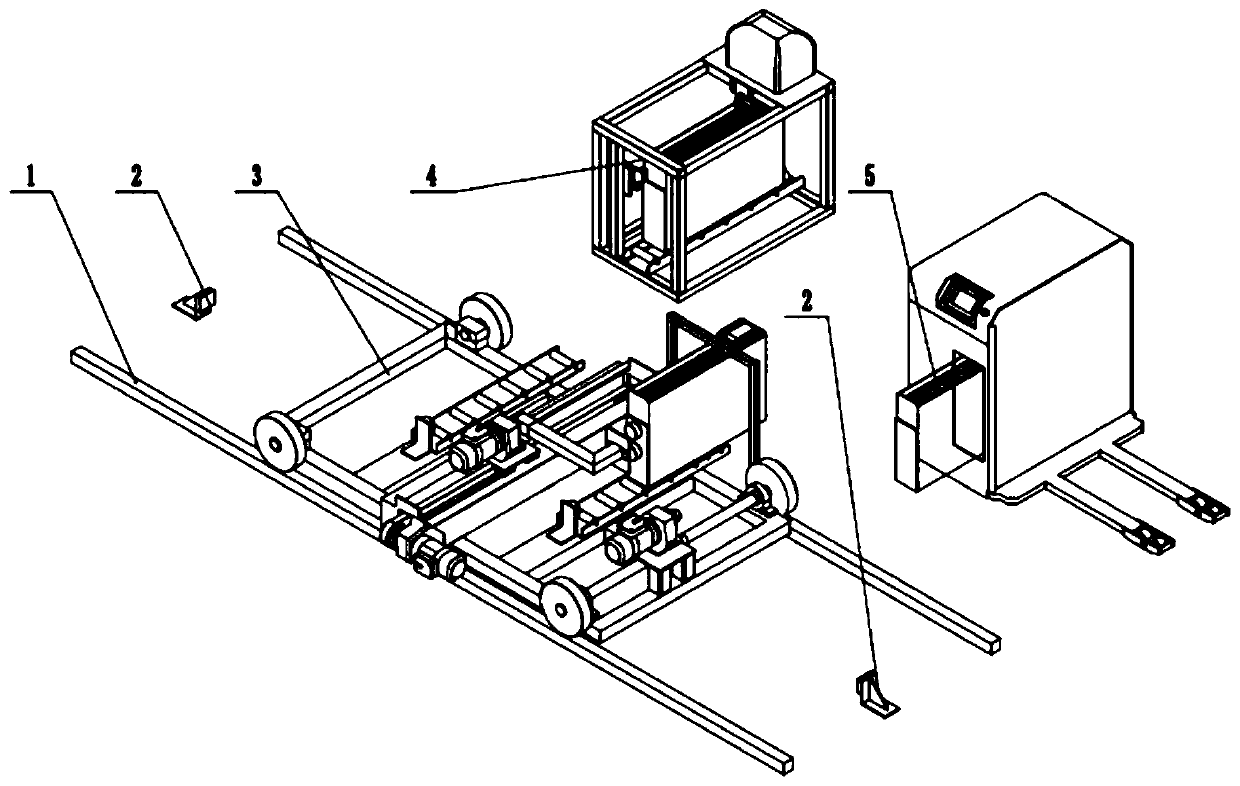

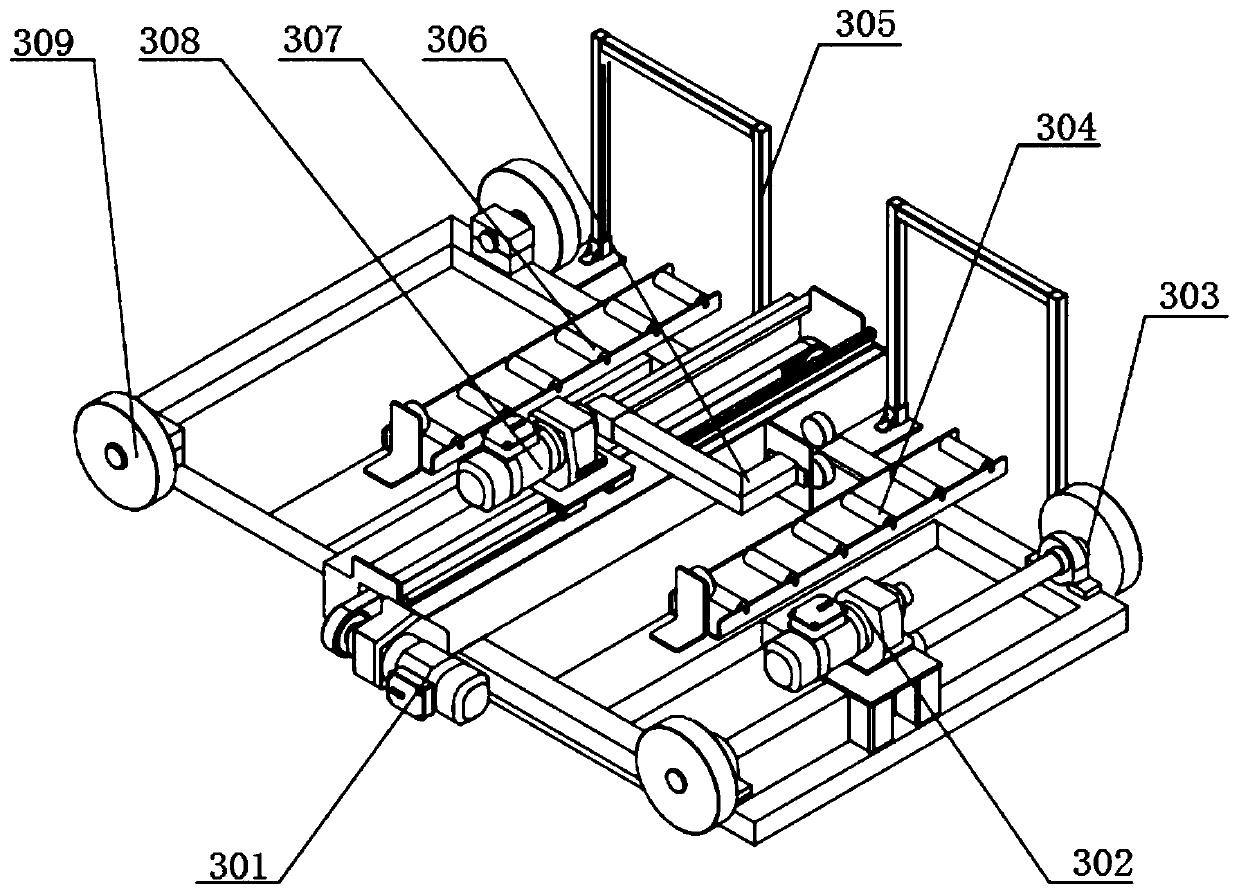

[0028] Such as Figure 1-Figure 2 As shown: this embodiment provides an automatic battery changing device, including a guide rail 1 and a battery transfer mechanism 3, two guide rails 1 are laid in parallel on the same plane, and the battery transfer mechanism 3 includes a walking structure, a push-pull Structure, rotating structure, fully charged battery position 304 and power-deficient battery position 307, the walking structure is rolled on the guide rail 1, the walking structure is fixedly provided with a base, push-pull structure, rotating structure, fully charged battery position 304 and power-deficient battery position 307 are all arranged on the base, the rotating structure is fixed on the push-pull structure, and the rotating structure is connected with a mechanical arm 306. The mechanical arm 306 is used to push and pull the battery and is placed on the fully charged battery position 304 or the low-power battery position 307. 306 can drag out the power-depleted batte...

Embodiment 2

[0038] This embodiment provides a method for using an automatic battery changing device, which uses the automatic battery changing device in Embodiment 1, and includes the following steps:

[0039] Step1, the automatic battery changing device receives the battery replacement request of the industrial equipment 5; the battery transfer mechanism 3 moves on the guide rail 1, aligns the fully charged battery position 304 with the fully charged battery on the rechargeable battery position in the battery charging rack 4, and Drag the fully charged battery into the fully charged battery position 304;

[0040] Step2. The battery transfer mechanism 3 moves in the opposite direction on the guide rail 1, and aligns the battery position 307 with the power-deficient battery with the battery access opening of the industrial equipment 5, and drags the power-deficient battery from the industrial equipment 5 and drops it to the power-deficient battery bit 307;

[0041] Step3. The battery tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com