Continuously variable power-split transmission

A kind of transmission equipment and shunt technology, which is applied in the direction of transmission devices, mechanical equipment, gear transmission devices, etc., can solve problems such as poor transmission efficiency, and achieve the effect of reducing complexity and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

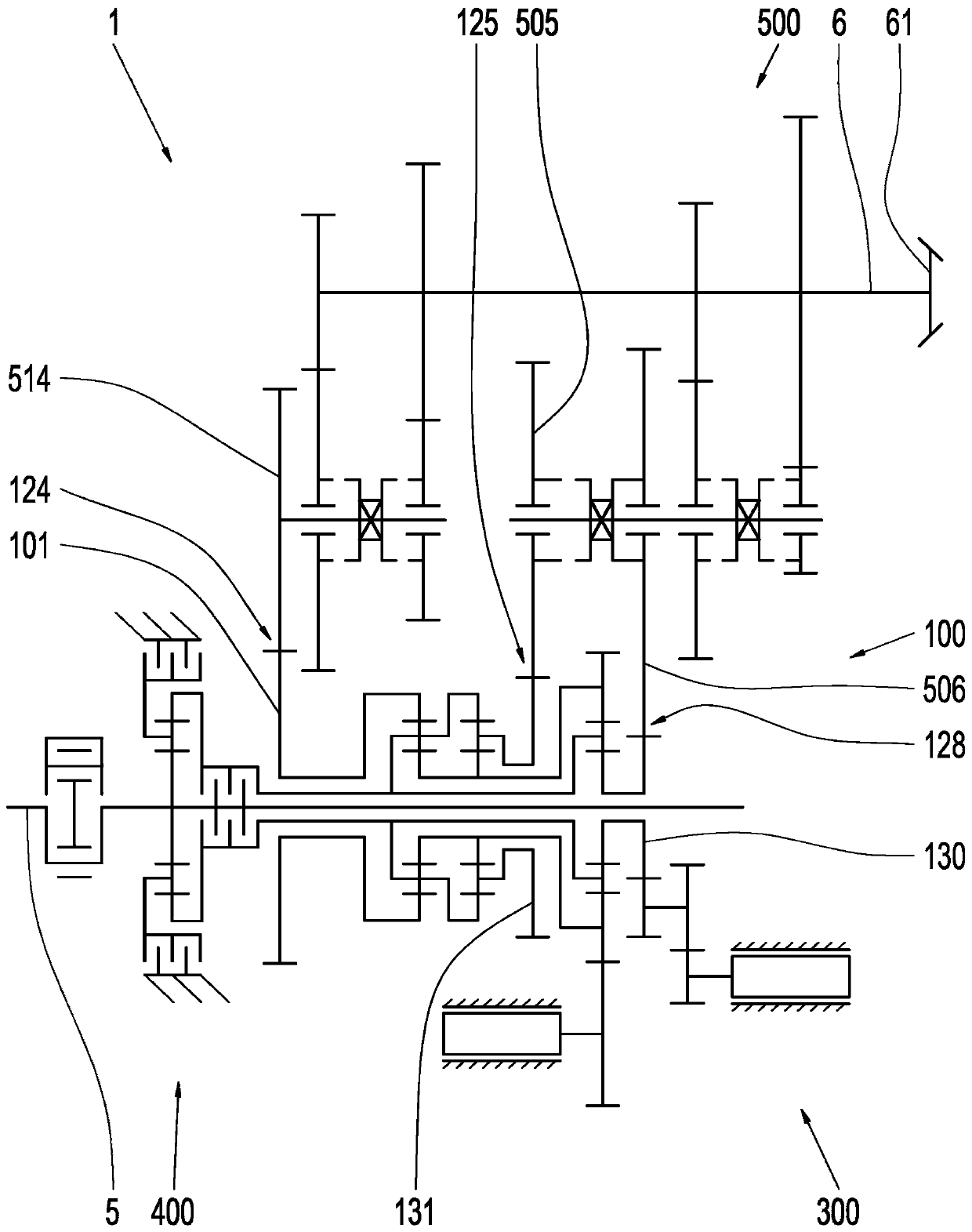

[0037] Embodiments are described below with reference to the drawings. Identical or similar elements are marked with the same reference numerals in different figures.

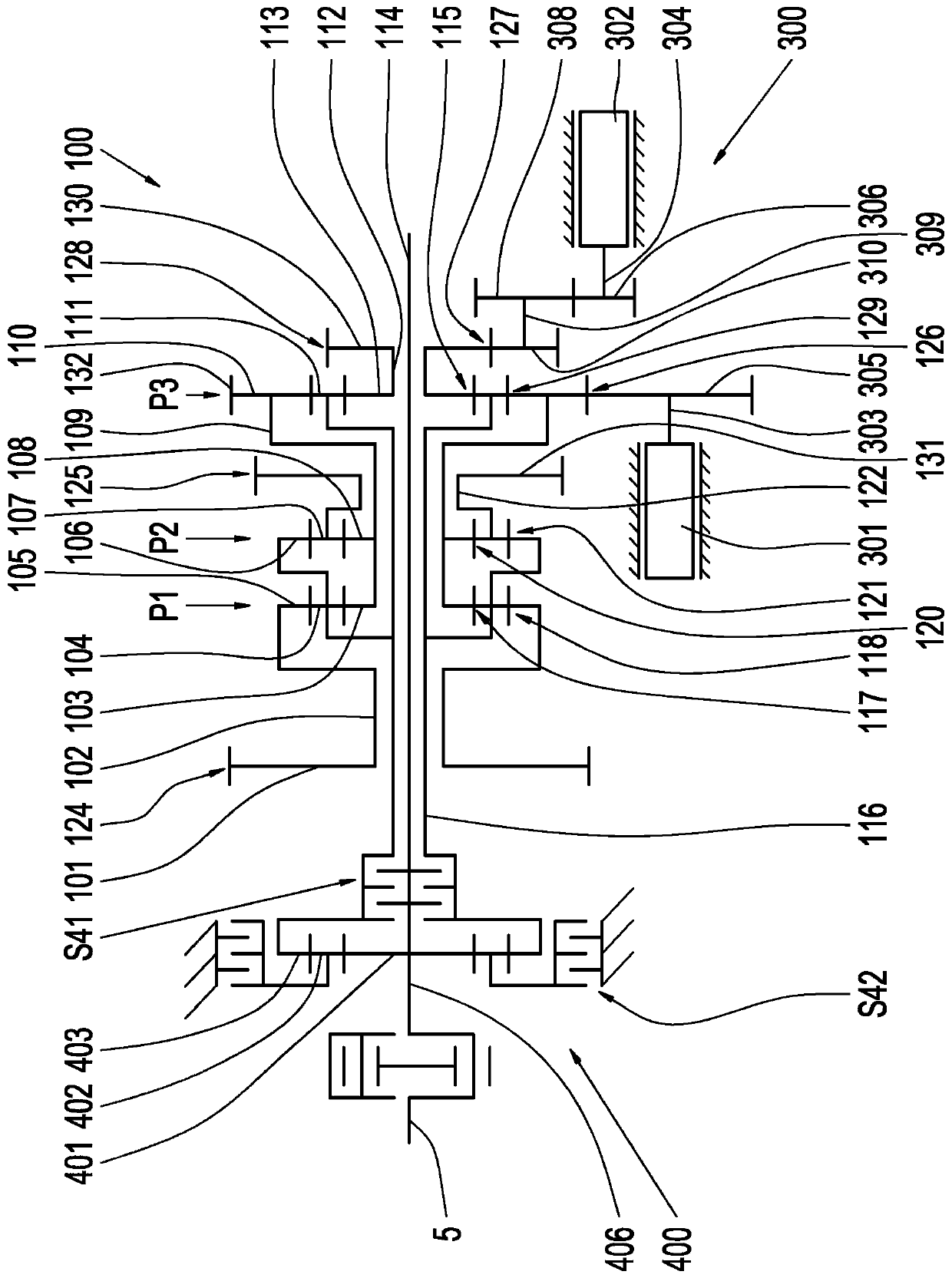

[0038] figure 1 A portion of a continuously variable power-split transmission is shown. More precisely, in figure 1 The planetary gear unit 100 , the reversing gear unit 400 and the transmission unit 300 are shown in FIG.

[0039] The transmission input shaft 5 is connected to the input shaft 406 of the reversing transmission device 400 . The reversing transmission 400 connects the input shaft 406 to the input shaft 116 of the planetary gear unit 100 so that the direction of rotation can be reversed. The reversing gear 400 is designed as a planetary gear, wherein the sun gear 401 is rotationally fixedly connected to the input shaft 406 . The planetary assembly 402 meshes with the sun gear 401 on the one hand and with the ring gear 403 on the other hand. Ring gear 403 is rotationally fixedly connected to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com