An impeller type gas meter with temperature difference compensation

A temperature difference compensation, impeller-type technology, applied in the field of gas measurement, can solve the problems of unstable measurement performance of gas meters, and achieve the effect of ensuring movement balance and realizing automatic temperature difference compensation and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is further described in detail through specific implementation methods:

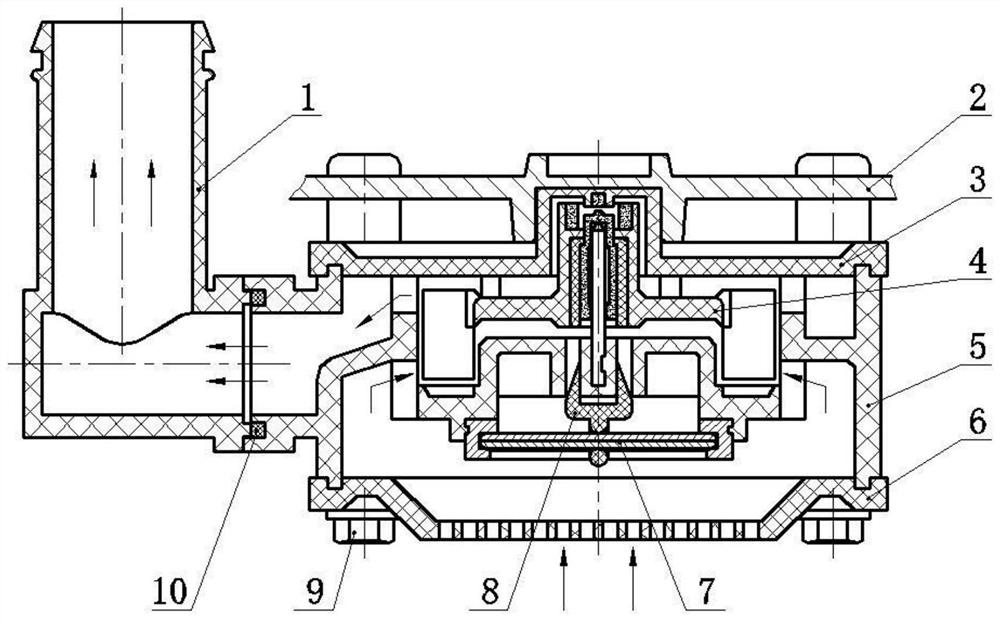

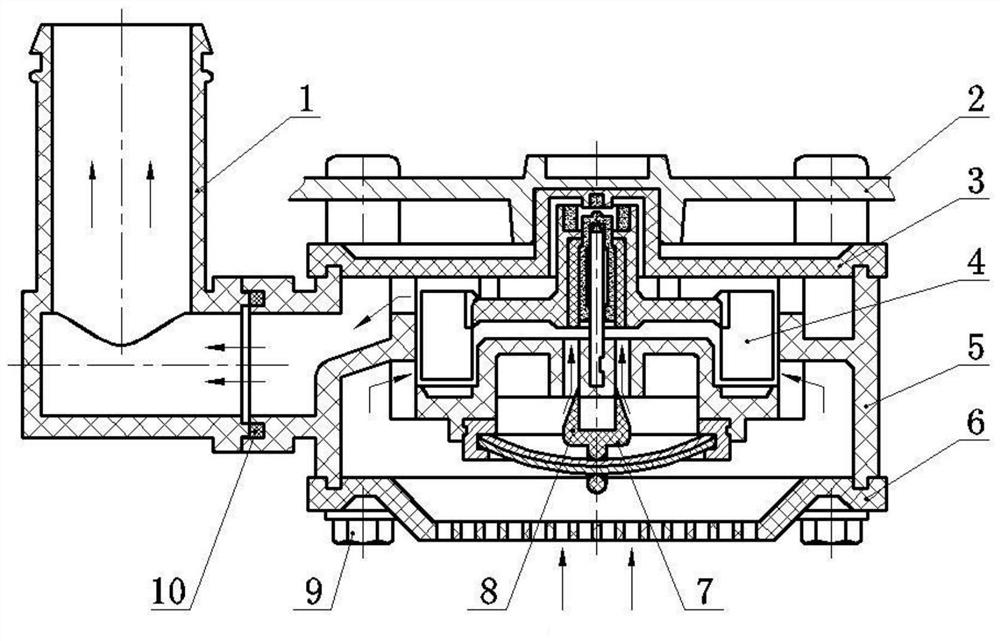

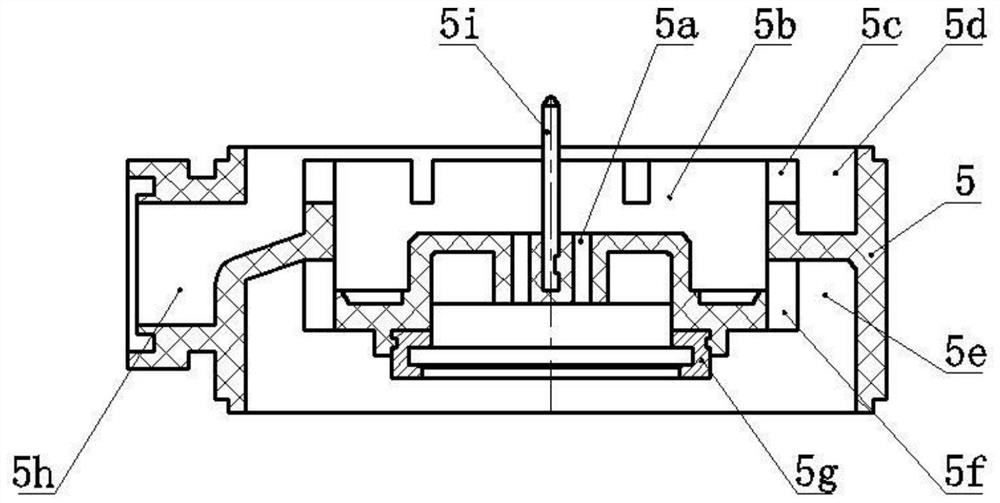

[0032] The reference signs in the drawings of the specification include: air outlet 1, gas meter box body 2, upper sealing plate 3, impeller 4, blade 4a, shaft sleeve 4b, sensing element 4c, measuring box 5, error adjustment hole 5a, measuring Chamber 5b, oblique air outlet 5c, annular flow channel 5d, lower channel chamber 5e, oblique guide hole 5f, metal insert 5g, air outlet 5h, wear-resistant rotating shaft 5i, lower sealing plate 6, filter screen 6a, temperature control sheet 7. Slider 8, bolt 9, sealing ring 10.

[0033] The embodiment is basically as attached figure 1 and figure 2 Shown:

[0034] An impeller-type gas meter with temperature difference compensation, comprising a gas meter box body 2 with an air inlet and an air outlet 1, the air outlet 1 is an angular air outlet, and the end surface of the connection between the air outlet 1 and the measurement box 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com