Partition plate deflection measuring system

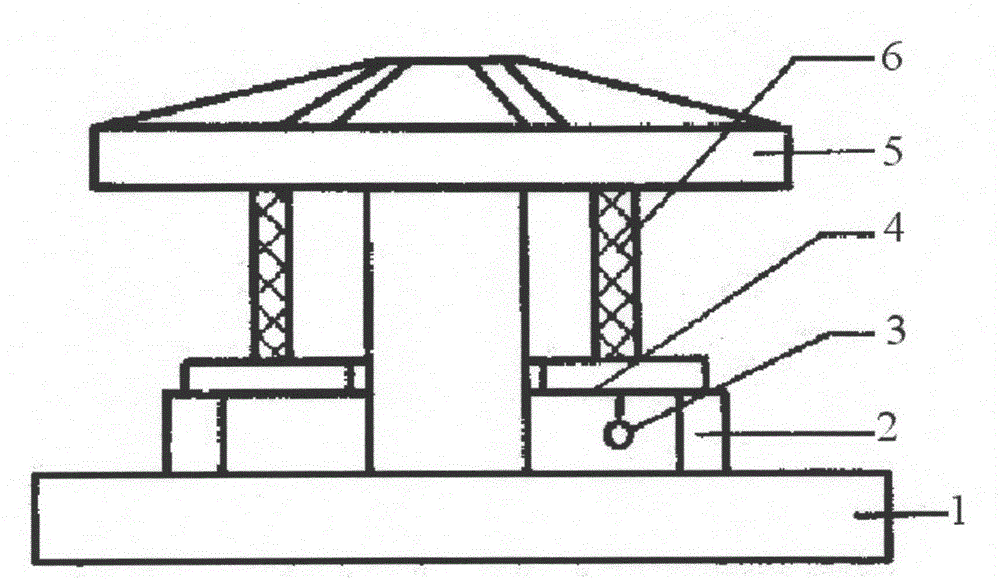

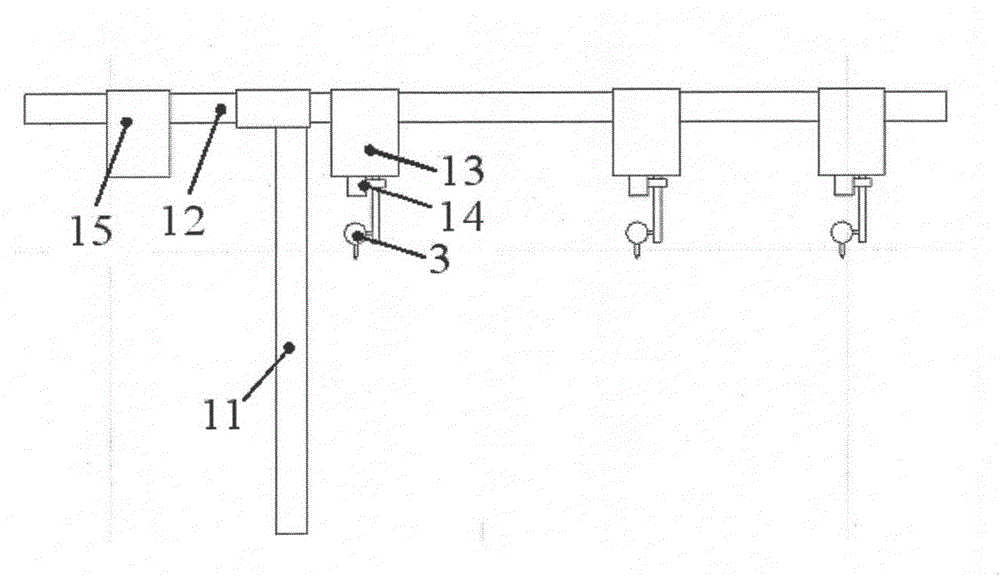

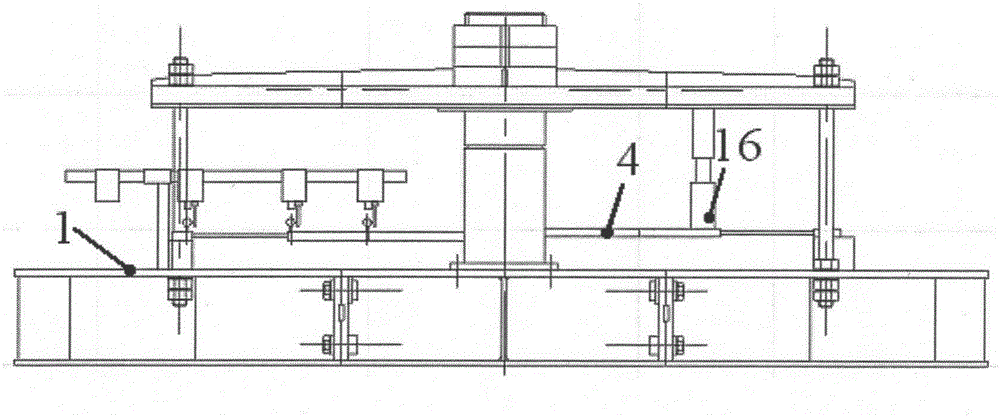

A technology for measuring system and diaphragm deflection, which is applied in the direction of mechanical roughness/irregularity measurement, mechanical solid deformation measurement, etc. It can solve the problems that the accuracy of diaphragm deflection measurement cannot be guaranteed, and it is difficult to ensure the stiffness and flatness of the measurement plane. , to offset measurement errors and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The simulated test diaphragm that requires deflection testing has a diameter of 5.2 m and a thickness of 0.07 m, and the total force exerted on the diaphragm is 2894 kN.

[0031] Using a traditional detachable diaphragm deflection test bench with a diameter of 7m, after testing, the maximum deflection of the diaphragm is 1.73mm, and the measured deformation of the corresponding part of the test bench is 0.29mm, and the error caused by the deformation of the test bench to 16.8%.

[0032] By adopting the diaphragm deflection measuring system of the present invention, the error caused by the deformation of the test table surface is eliminated, and the measuring accuracy is increased by 16.8%.

Embodiment 2

[0034] The diameter of the high-pressure first-stage diaphragm of a certain type of steam turbine that needs to be tested for deflection is 0.66m, the thickness is 0.3m, and the total force exerted on the diaphragm is 2990kN.

[0035] Using a traditional detachable diaphragm deflection test bench with a diameter of 7m, after testing, the maximum deflection of the diaphragm is 0.90mm, and the measured deformation of the corresponding part of the test bench is 0.22mm, and the error caused by the deformation of the test bench to 24.4%.

[0036] By adopting the diaphragm deflection measuring system of the present invention, the error caused by the deformation of the test table surface is eliminated, and the measuring accuracy is increased by 24.4%.

[0037] To sum up, for the traditional detachable diaphragm deflection test bench with a table diameter of 7m, due to the large body, the flatness of the table and the deformation of the table have a great influence on the measurement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Deflection | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com