Knife hitting plate wear automatic compensating method of contact type knife damage detection system

An automatic compensation and damage detection technology, which is applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems affecting the measurement accuracy of the tool damage detection system, false alarms of machine tools, and increased use and maintenance costs of machine tools. Achieve the effects of offsetting measurement errors, reducing replacement or correction, and increasing service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

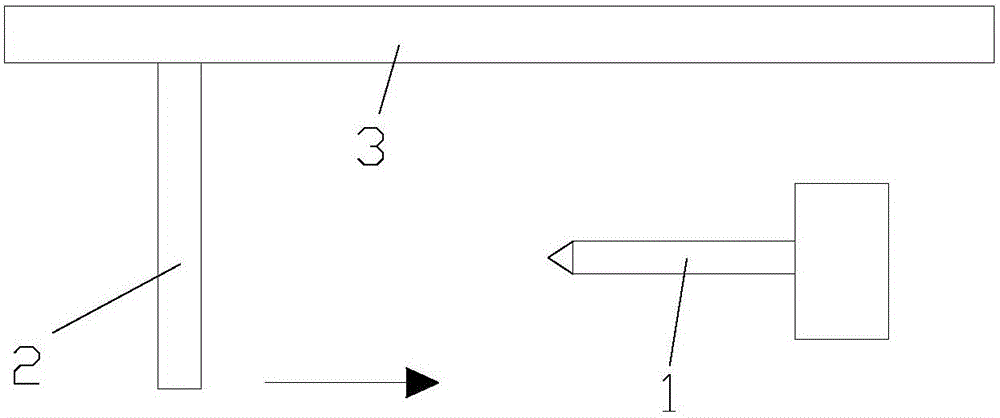

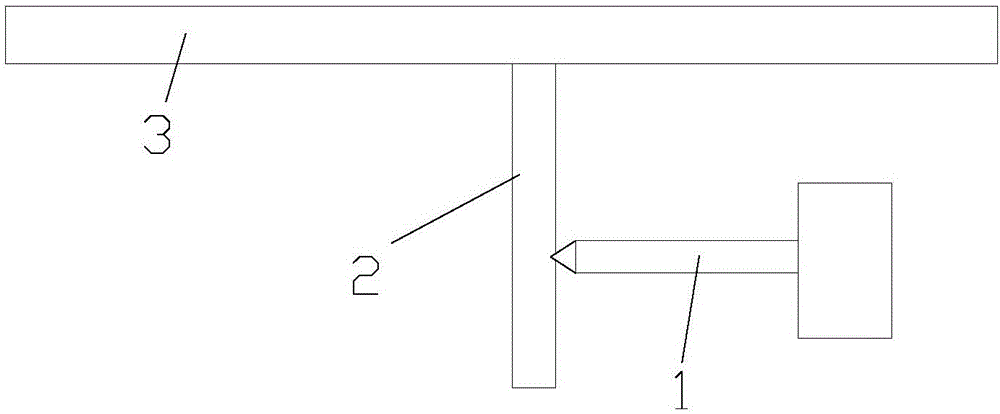

[0015] as attached figure 1 As shown in the figure, an automatic compensation method for the wear of the cutting plate of a contact tool breakage detection system includes the cutting plate 2 which conflicts with the tool 1 and the driving part 3 for controlling the movement of the cutting plate 2. The equipment control system calculates the cutting plate The wear value of the collision between the plate 2 and the tool 1 is automatically compensated for the measured length of the tool 1.

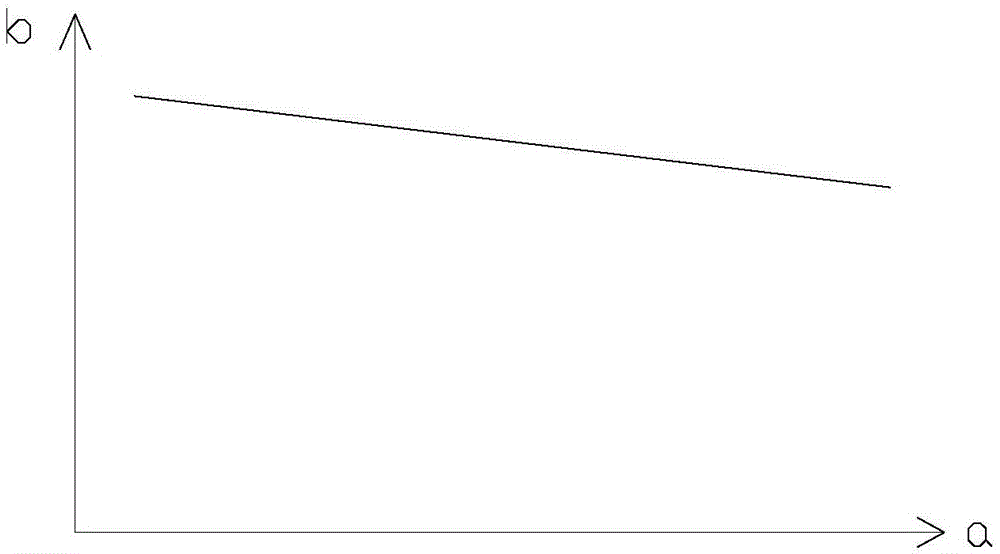

[0016] When detecting the length of the cutter 1, the beating plate 2 moves forward to contact with the tip of the cutter. According to the wear condition of the knife plate 2 in actual use, a pit will gradually form on the surface of the knife plate 2, so the stop position of the knife plate 2 will be more forward than before it is not worn normally, and the corresponding tool 1 damage detection system will measure The length of the output tool 1 will be relatively small, such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com