Personal cleansing composition

A composition and polymer technology, applied in hair care, cosmetic preparations, pharmaceutical formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

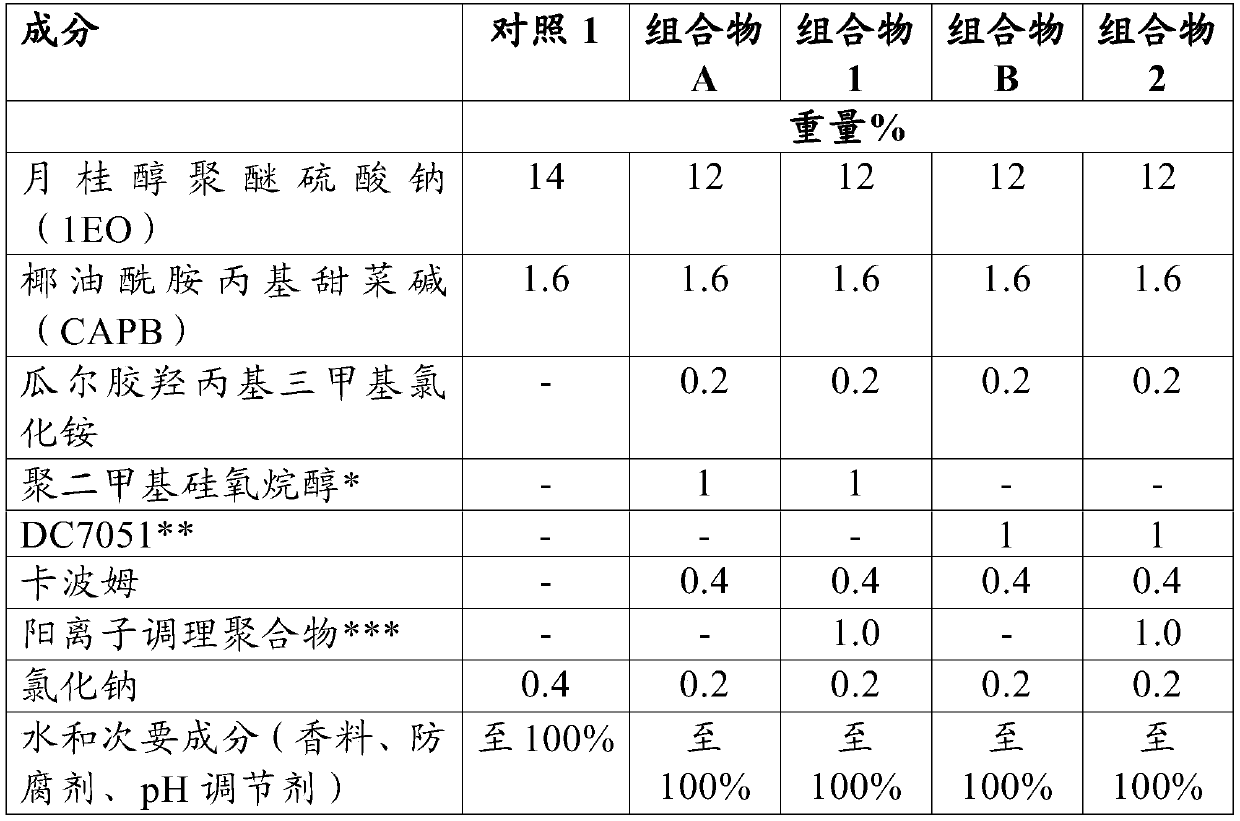

[0099] Example 1: Compositions 1-2 according to the invention, comparative compositions A-B and control 1

[0100] A hair cleansing shampoo formulation having the ingredients shown in Table 1 was prepared. Compositions 1-2 are according to the invention; compositions A-B are comparative examples. All weight percentages (wt %) quoted are by weight based on the total weight unless otherwise indicated.

[0101] Table 1: Composition (% by weight) of compositions 1-2 according to the invention, comparative compositions A-B and control 1

[0102]

[0103] *Emulsion of dimethiconol with anionic emulsifier, average particle size < 1 micron (from Dow)

[0104] **Dowsil CE-7051POE Emulsion Silicone Blend from Dow

[0105] ***N-DurHance TM A-1000 Conditioning Polymer (from Ashland Inc.); 20% actives

[0106] Shampoo Compositions 1-2, Comparative Compositions A-B and Control were prepared by the following method:

[0107] 1. Thoroughly disperse the cationic conditioning polyme...

Embodiment 2

[0115] Example 2: Treatment of Hair with Compositions 1-2, Comparative Compositions A-B and Control 1

[0116] The hair used was dark brown European hair, tresses weighing 2.5 g and 6 inches in length. In these embodiments, this is referred to as untreated hair.

[0117] Bleached hair was prepared as follows:

[0118] Platine PrecisionWhite Compact Lightening Powder (L'Oreal Professionnel Paris, Paris, France) mixed with 9% cream peroxide, 30'vol' (Excel GS Ltd, UK) (60g powder mixed with 120g cream peroxide ) bleach the hair for 30 minutes at a time. Then rinse hair with water for 2 minutes. Hair was treated with the formulations described in Table 1 during a typical wash regimen. The treated hair was then evaluated for the amount of silicone deposited on the surface and the level of friction when the hair was dry.

[0119] Hair was treated with the shampoo compositions: Compositions 1-2, Comparative Compositions A-B and Control 1 using the following method:

[0120] ...

Embodiment 3

[0122] Example 3: Silicone Deposition on Hair Treated with Compositions 1-2, Comparative Compositions A-B and Control 1

[0123] The treated tresses were rinsed and dried before quantifying the amount of silicone deposited on the hair surface using x-ray fluorescence (XRF).

[0124] Five replicates were prepared for each test formulation. The average amount of silicone deposited on the hair is shown in Table 2.

[0125] Table 2: Silicone deposition (ppm) on bleached hair treated with compositions 1-2 according to the invention, comparative compositions A-B and control 1

[0126] combination hair type Silicone deposition (PPM) s.d. Control 1 bleached 0 10.07 Composition A bleached 30.32 4.52 Composition 1 bleached 164.06 17.54 Composition B unprocessed 408.6 39.46 Composition 2 unprocessed 650.6 39.84

[0127] It will be seen that the amount of silicone deposited onto the hair is significantly higher for compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap