A kind of preparation method of zinc alloy wire for spraying gold on the end face of metallized film capacitor

A technology of metallized film and zinc alloy, which is applied in the field of preparation of zinc alloy wire for gold spraying on the end face of metallized film capacitors, can solve the problems that the strength of the alloy has little effect and cannot significantly improve the strength, and achieve the effect of ensuring smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

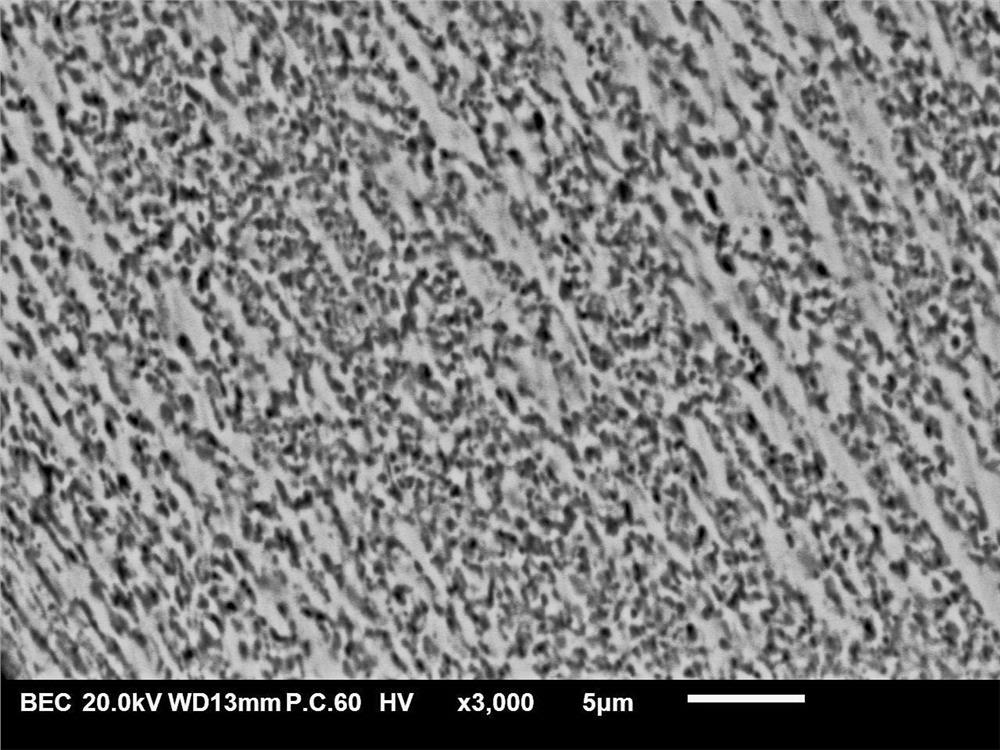

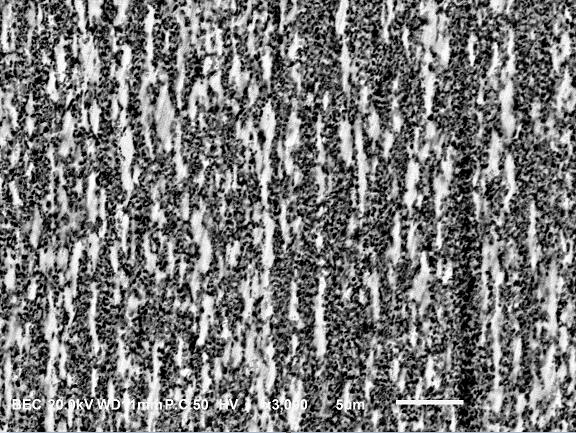

Image

Examples

preparation example Construction

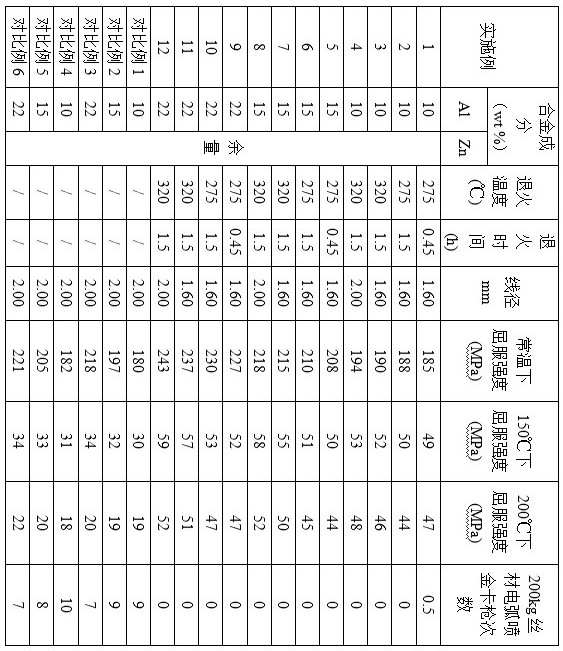

[0027] A preparation method of a zinc alloy wire for spraying gold on the end face of a metallized film capacitor, comprising the following steps:

[0028] (1) Raw material ratio;

[0029] (2) After melting the proportioned raw materials in the intermediate frequency furnace, the continuous casting billet rod with a certain wire diameter is obtained by continuous casting;

[0030] (3) Reduce the diameter of the billet rod into a continuous thick wire billet;

[0031] (4) Thick wire billets are heat treated, the furnace temperature is 275-320°C, and the holding time is 0.45-1.5h;

[0032] (5) After heat treatment, the thick wire billet is naturally cooled in an environment not lower than 20°C;

[0033] (6) The thick wire billet after natural cooling is drawn and reduced.

[0034] Further, the raw material ratio is 10-22%wt of aluminum, and the balance is zinc.

[0035] Further, the drawing and reducing diameters are firstly drawn and reduced by using two continuous roller d...

Embodiment 1

[0039] Example 1, a method for preparing a zinc alloy wire for spraying gold on the end face of a metallized film capacitor, comprising the following steps: 10%wt of aluminum (Al) and the balance of zinc (Zn) in an intermediate frequency furnace After melting, the continuous casting method is used to obtain a continuous billet with a wire diameter of Φ14mm; the Φ14mm billet is processed into a continuous Φ4.0mm thick wire billet through continuous rolling through reducing processing; the thick wire billet is put into a heat treatment furnace for For processing, the furnace temperature is 275°C, and the holding time is 0.45 hours; take the thick wire billet out of the furnace, and cool it naturally in the air not lower than 20°C; Die drawing and reducing to Φ1.66mm wire diameter, the continuous drawing and reducing process temperature does not exceed 70°C; the finished wire drawing die is drawn, and its specification size is Φ1.60mm, while drawing, apply lubricating oil to the s...

Embodiment 2

[0040] The difference between Example 2 and Example 1 is that the holding time of the heat treatment of the thick wire billet is 1.5 hours; the content of lubricating oil drawn by the finished wire drawing die is 0.009%wt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com