Material transferring device for coastal engineering construction

A technology for engineering construction and transfer devices, which is applied in hoisting devices, transportation and packaging, lifting equipment braking devices, etc., can solve problems such as potential safety hazards and material shaking, and achieve the goals of improving safety, avoiding shaking, and improving versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

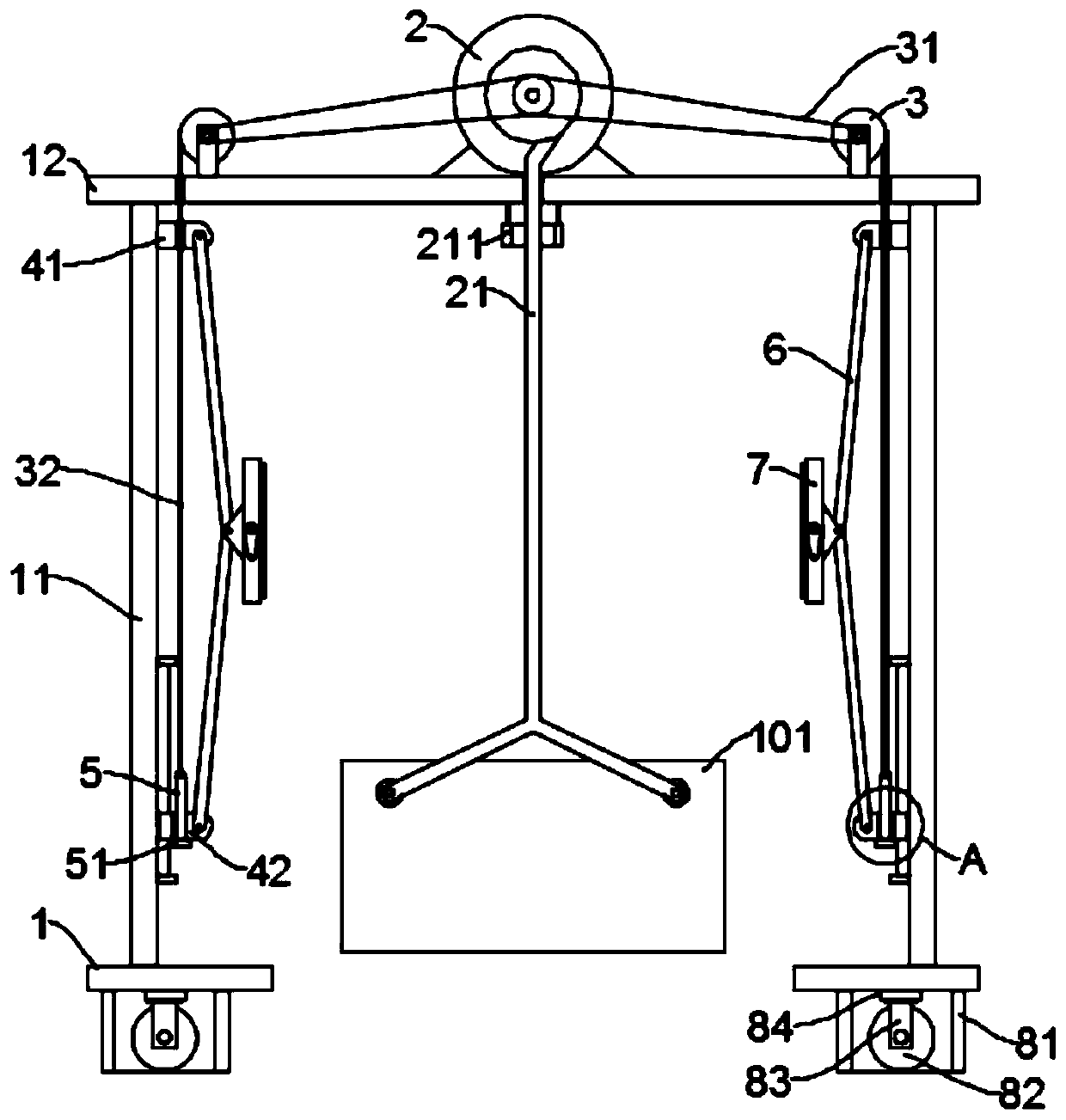

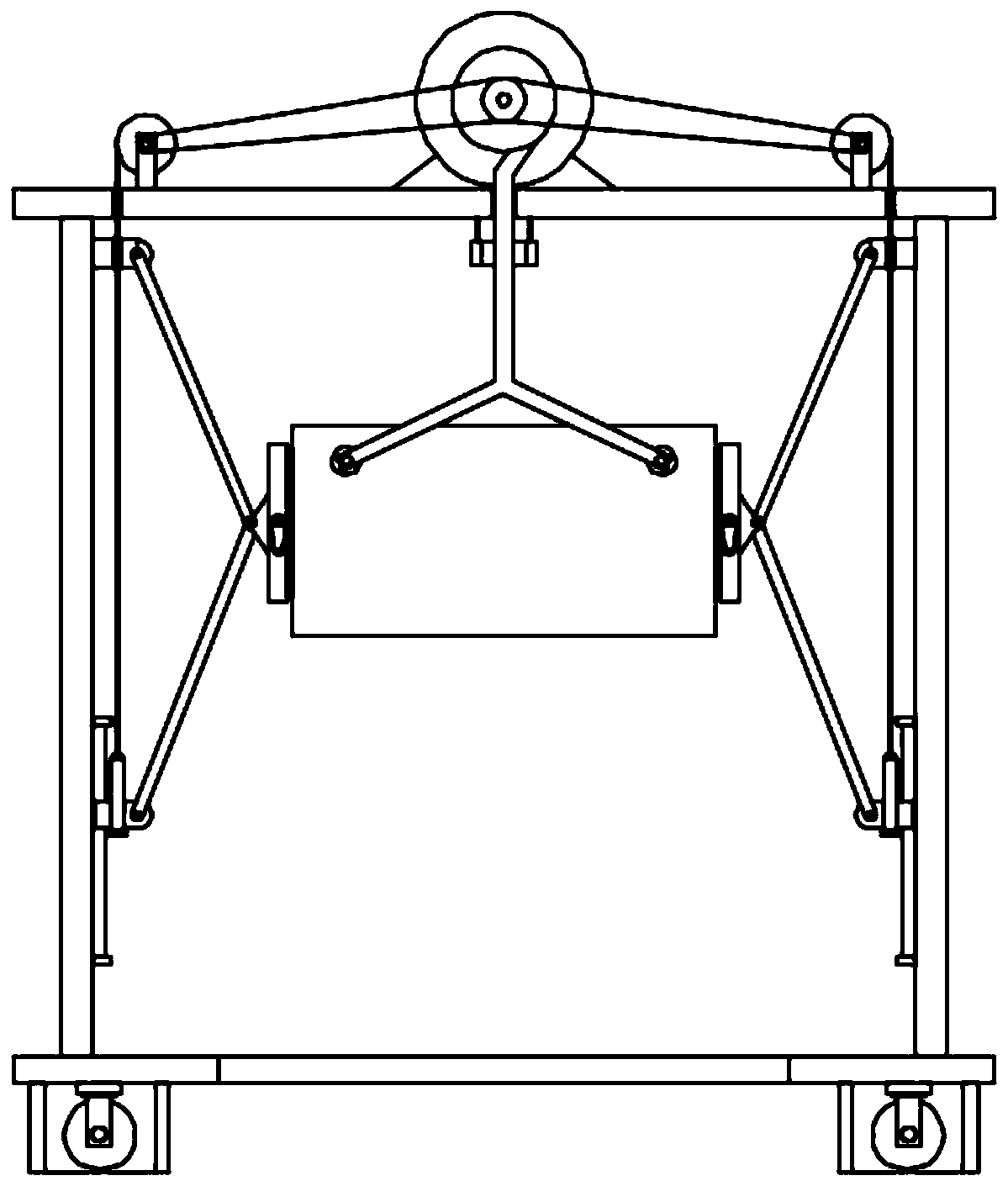

[0023] see Figure 1~5 , in an embodiment of the present invention, a material transfer device for coastal engineering construction, including two symmetrically arranged bases 1, a stand 11 fixed to the base 1, and a top plate 12 fixed to the top of the two stand 11, the base 1 The bottom is equipped with a walking mechanism; the top center of the top plate 12 is equipped with a hoist 2, and the reel of the hoist 2 is wound with a sling 21 for lifting the material box 101. During work, the material is loaded in the material box 101, and then Utilize the winch 2 to lift the material box 101, and then use the traveling mechanism to drive the material box 101 to move to the designated location to complete the transfer.

[0024] In order to better guide the suspension rope 21 , in this embodiment, a guide ring 211 is fixed at the center of the bottom of the top plate 12 , and the guide ring 211 is sleeved around the periphery of the suspension rope 21 .

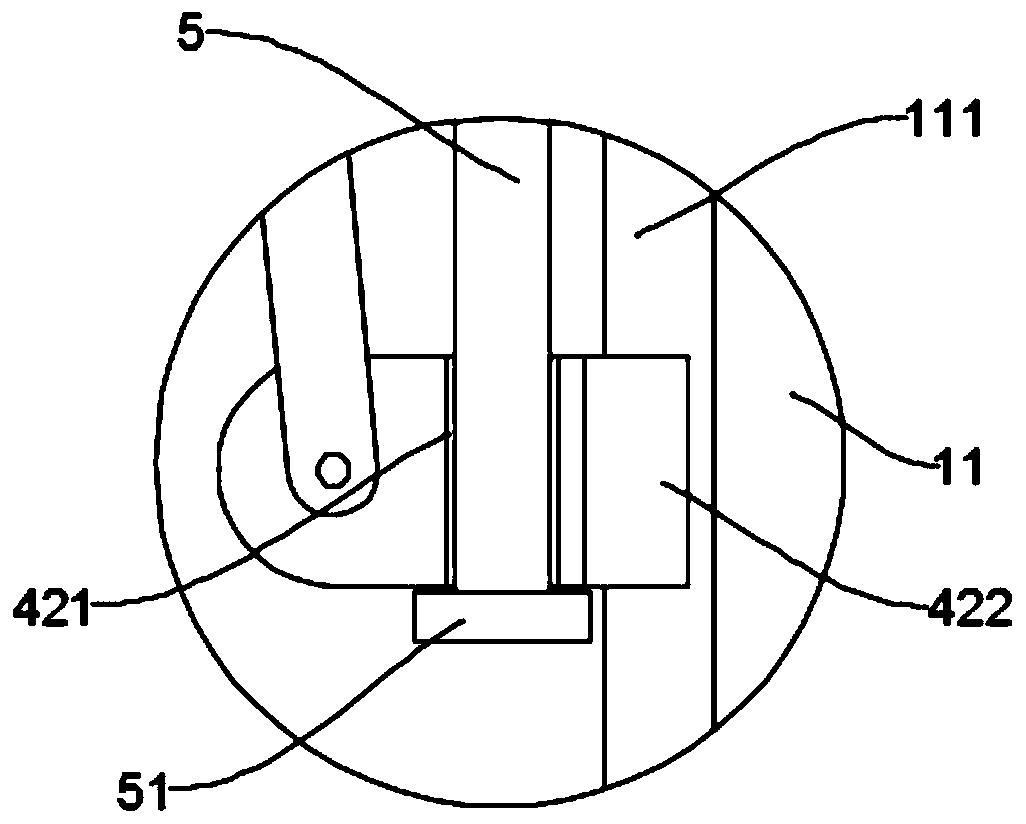

[0025] The top of the to...

Embodiment 2

[0034] The embodiment of the present invention optimizes the design of the running mechanism on the basis of embodiment 1, specifically:

[0035]Described walking mechanism comprises support cover 81 and roller 82, and described support cover 81 is fixed on the bottom of base 1, and the inner cavity top of support cover 81 is equipped with lifting device, and the movable end of lifting device is fixed with mounting frame 83, and mounting frame 83 Roller 82 is installed on the upper rotation, and when the lifting device is in the maximum stroke position upwards, the roller 82 is located in the support sleeve 81, so that during the lifting process, the roller 82 can be hidden in the support sleeve 81, and the support sleeve 81 is directly in contact with the ground to ensure stability, and when it needs to move, the lifting device drives the roller 82 to move downwards and stretch out the support sleeve 81.

[0036] The specific structure of the lifting device is not limited. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com