Substrate for transparent conductive film and transparent conductive film

A transparent conductive, thin-film technology, applied to the direction of the conductive layer on the insulating carrier, can solve the problems of whitening, curling, cracks, etc., and achieve the effects of whitening and crack suppression, and small phase difference in the plane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

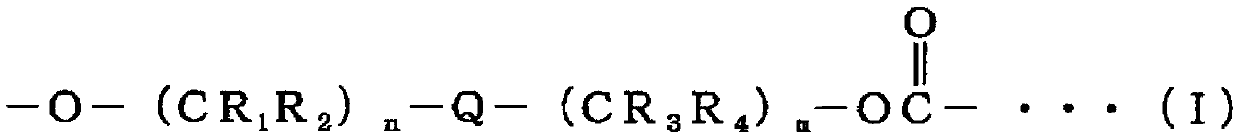

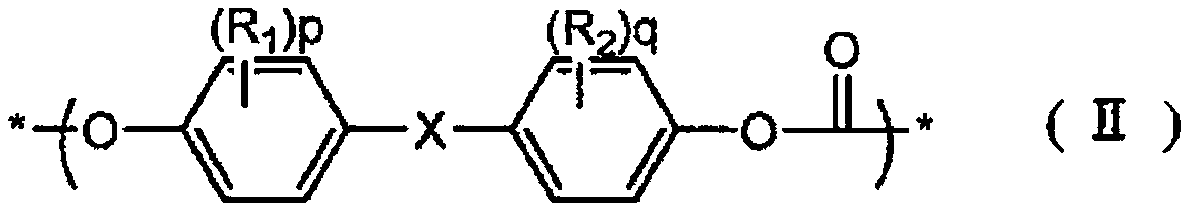

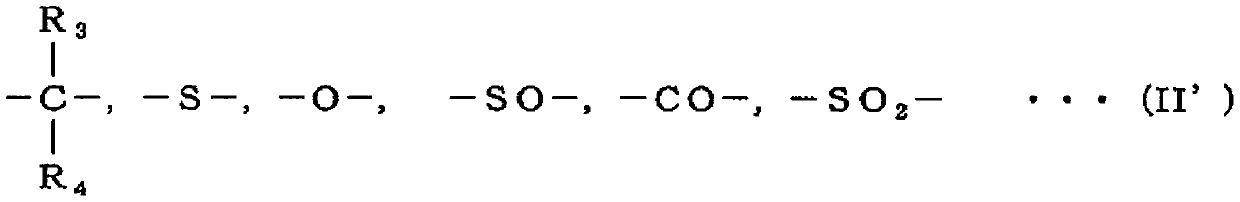

Method used

Image

Examples

Embodiment 1

[0143] 1-1. Production of polycarbonate resin film

[0144] The product name "Iupizeta (registered trademark)" (Tg: 174° C.) manufactured by Mitsubishi Gas Chemical Co., Ltd., which is a polycarbonate resin, was vacuum-dried at 120° C. for 5 hours, and then dried using a single-screw extruder (Isuzu Kakoki film production system, screw diameter 25mm, barrel set temperature: 295°C), T die (width 200mm, set temperature: 295°C), cooling roll (set temperature: 140~150°C) and coiler device to produce a polycarbonate resin film with a thickness of 100 μm.

[0145] 1-2. Preparation of base material for transparent conductive film

[0146] The polycarbonate resin film obtained above was simultaneously biaxially stretched twice in each of the longitudinal direction and the width direction. The stretching temperature is [Tg+25°C]. In this way, a substrate for a transparent conductive film (thickness: 25 μm) was obtained. The in-plane retardation Re(550) of the obtained base material...

Embodiment 2

[0150] Except having made thickness into 15 micrometers, it carried out similarly to Example 1, and obtained the base material for transparent conductive films. The in-plane retardation Re(550) of the obtained base material for transparent conductive films was 2.1 nm, and the dimensional change ratio (MD / TD) was 0.04 / 0.04. Furthermore, the transparent conductive film was obtained similarly to Example 1 using the obtained base material for transparent conductive films. The obtained transparent conductive film was subjected to the evaluations of (3) and (4) above. The results are shown in Table 1.

Embodiment 3

[0152] Except having made thickness into 40 micrometers, it carried out similarly to Example 1, and obtained the base material for transparent conductive films. The in-plane retardation Re(550) of the obtained base material for transparent conductive films was 2.8 nm, and the dimensional change rate (MD / TD) was 0.08 / 0.09. Furthermore, the transparent conductive film was obtained similarly to Example 1 using the obtained base material for transparent conductive films. The obtained transparent conductive film was subjected to the evaluations of (3) and (4) above. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap