Pipeline joint structure

A technology of pipe joints and pipe heads, applied in the direction of pipes/pipe joints/fittings, threaded connections, passing elements, etc., can solve the problems of exposed threads and inability to take into account detachable connections, and achieve the effect of avoiding exposed threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

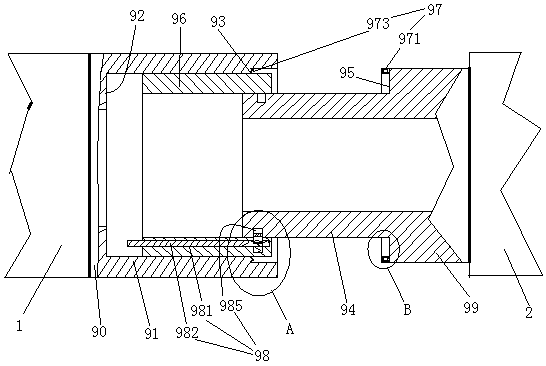

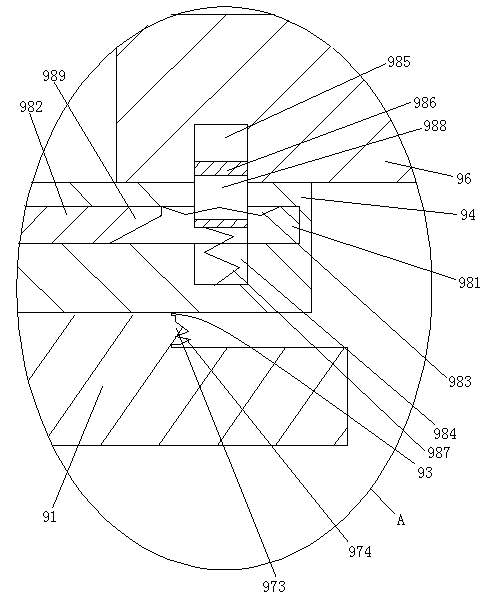

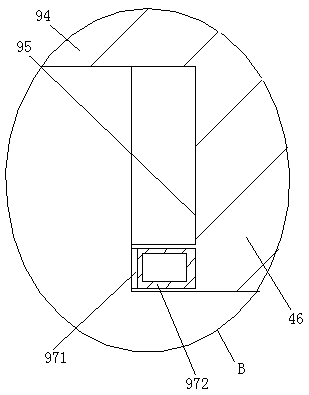

[0017] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a pipeline joint structure, including a first pipe head 90 and a second pipe head 99 . One end of the first pipe head is provided with an internally threaded pipe section 91 and a positioning step 92 at the inner end of the internally threaded pipe section. The outer end of the internally threaded pipe section is provided with a large-diameter section to form a first sealing step 93 . One end of the second pipe head 99 is provided with an externally threaded pipe section 94 . A second sealing step 95 is formed between the externally threaded pipe section and the second pipe head. The second pipe head 99 can be inserted into the large diameter section. The externally threaded pipe section is threadedly connected with an internally and externally threaded pipe section 96 sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com