A municipal water supply and drainage pipeline connection structure

A connection structure, water supply and drainage technology, applied in the direction of adjustable connection, flange connection, pipe/pipe joint/pipe fitting, etc., can solve the problems of prolonged operation time, low operation efficiency, increase of processing procedures, etc., and meet the requirements of operation skills. High, simple sealing and connection, low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

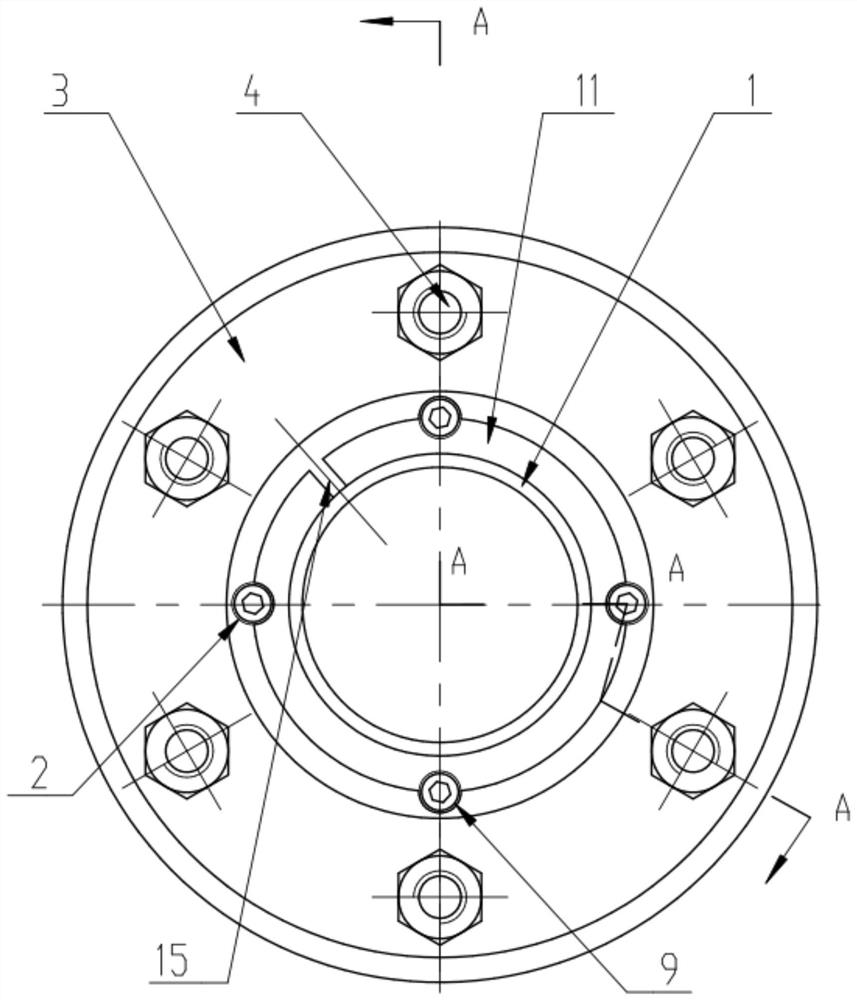

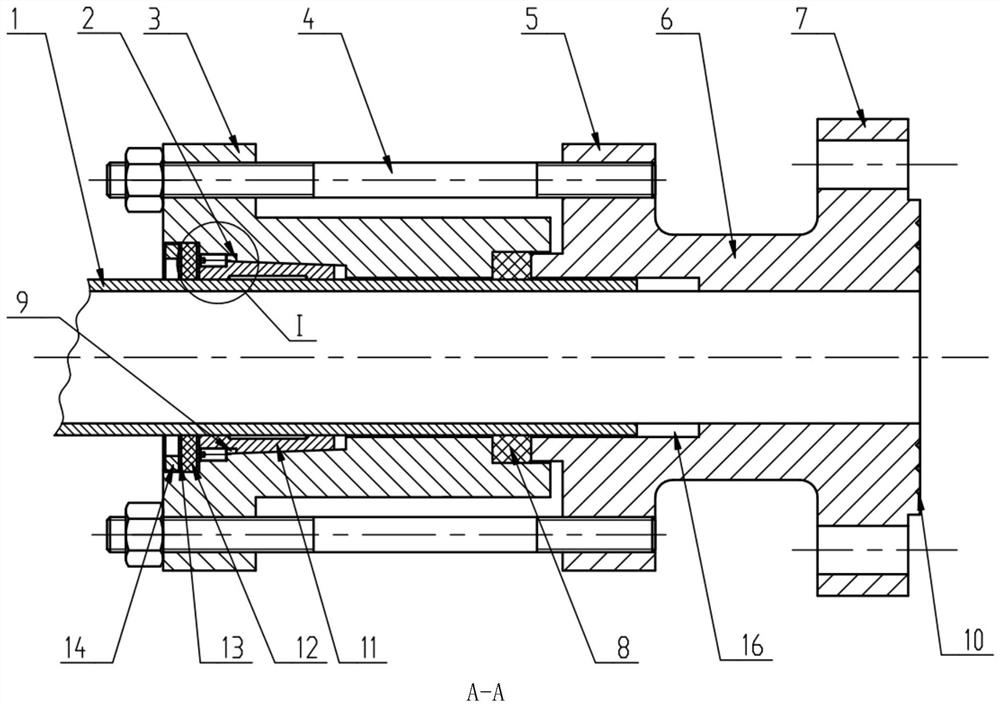

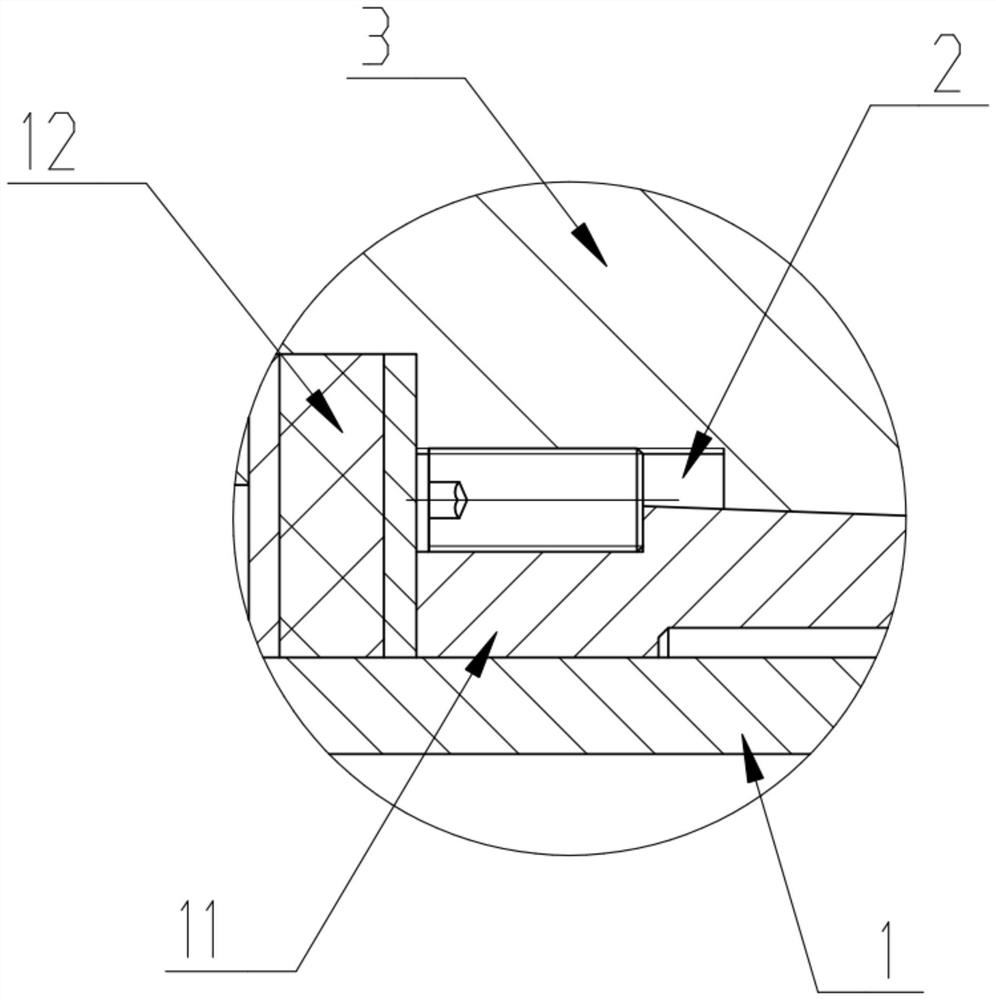

[0019] Such as Figure 1 to Figure 3 As shown, a municipal water supply and drainage pipe connection structure, which includes a circular connecting body 6 and a sealing unit arranged between the connecting body 6 and the pipeline 1, the center of the connecting body 6 is provided with a The through hole for the fluid, the right end of the connecting body 6 is a circular connecting flange 7, and the center of the left end is provided with an axial mounting hole 16, the pipe 1 is inserted in the mounting hole 16 and is slidingly fitted with the connecting body 6 . The present invention is used in pairs, and the connecting body 6 can slide axially along the pipe 1, so that the distance between the end of the pipe 1 and the connecting flange 7 can be adjusted, so that the distance between the end faces of the two pipes 1 to be connected can be adjusted. The accuracy requirement is not high, which is especially suitable for pipeline 1 rescue. When the pipeline 1 leaks, it is onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com