High-efficiency energy-saving heat exchange device

A heat exchange device, high-efficiency and energy-saving technology, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of wasting energy, increasing the cost of developing salons, barbershops, family kitchens, and family bathrooms. To achieve the effect of long service life, favorable heat exchange and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

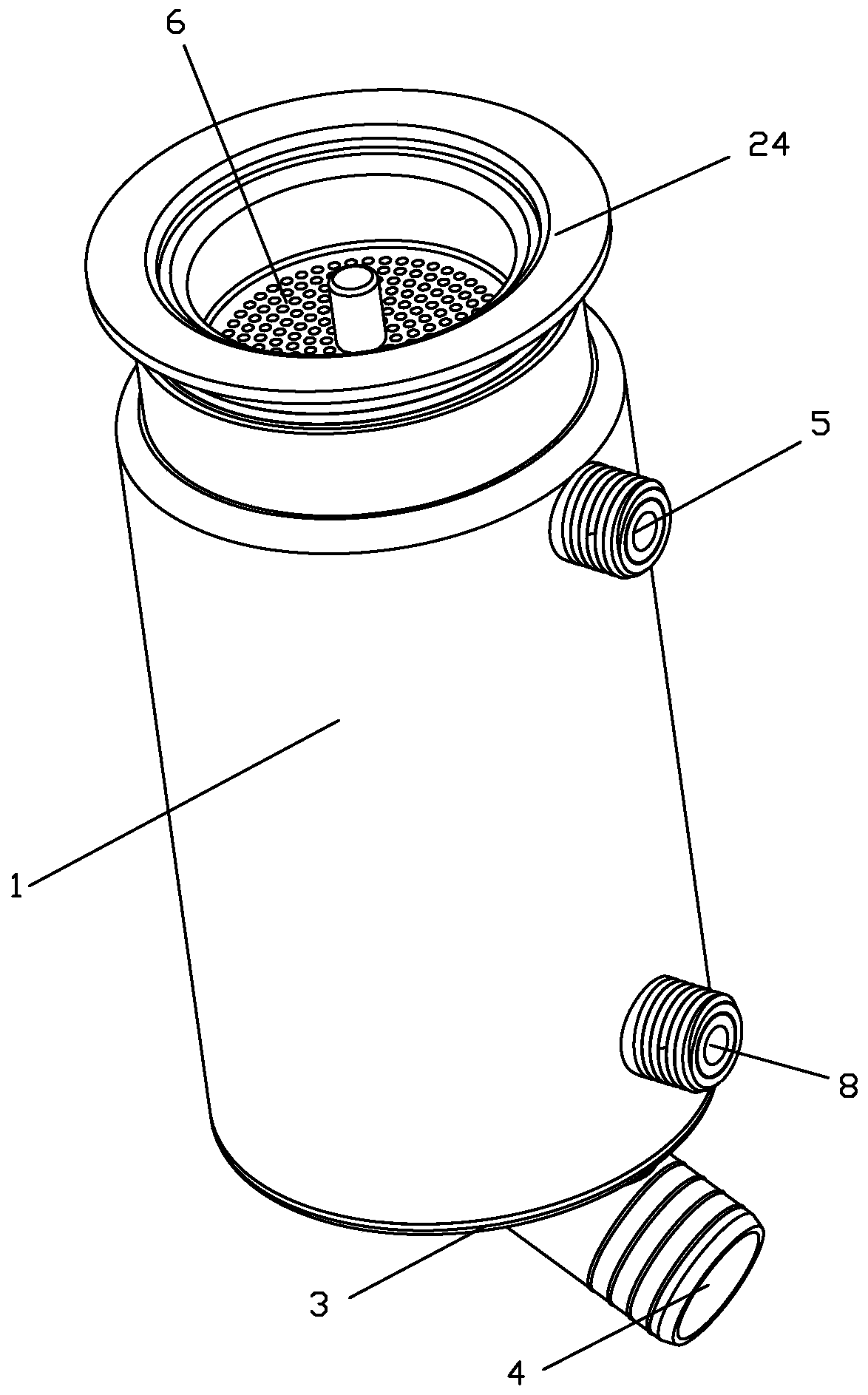

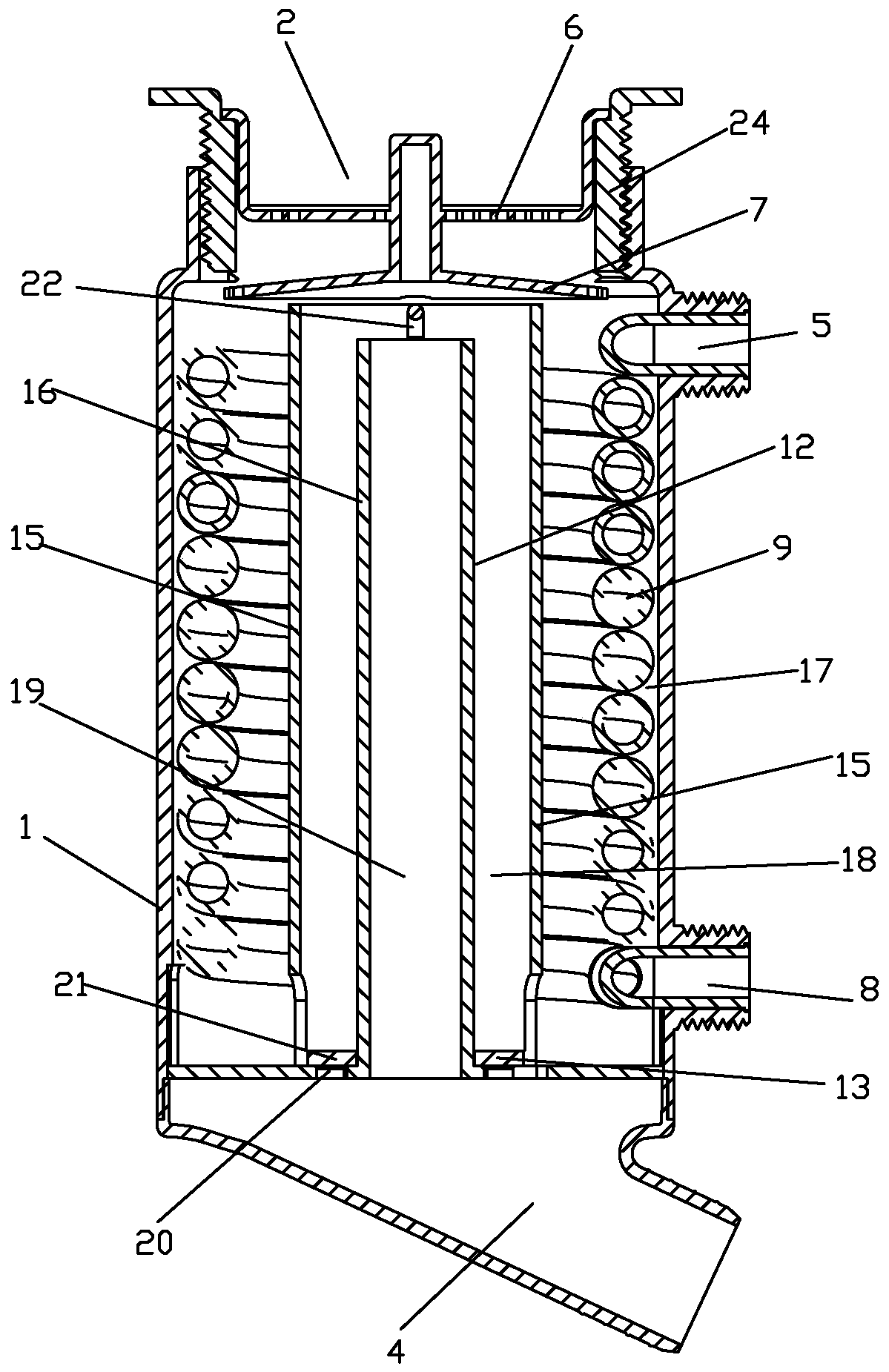

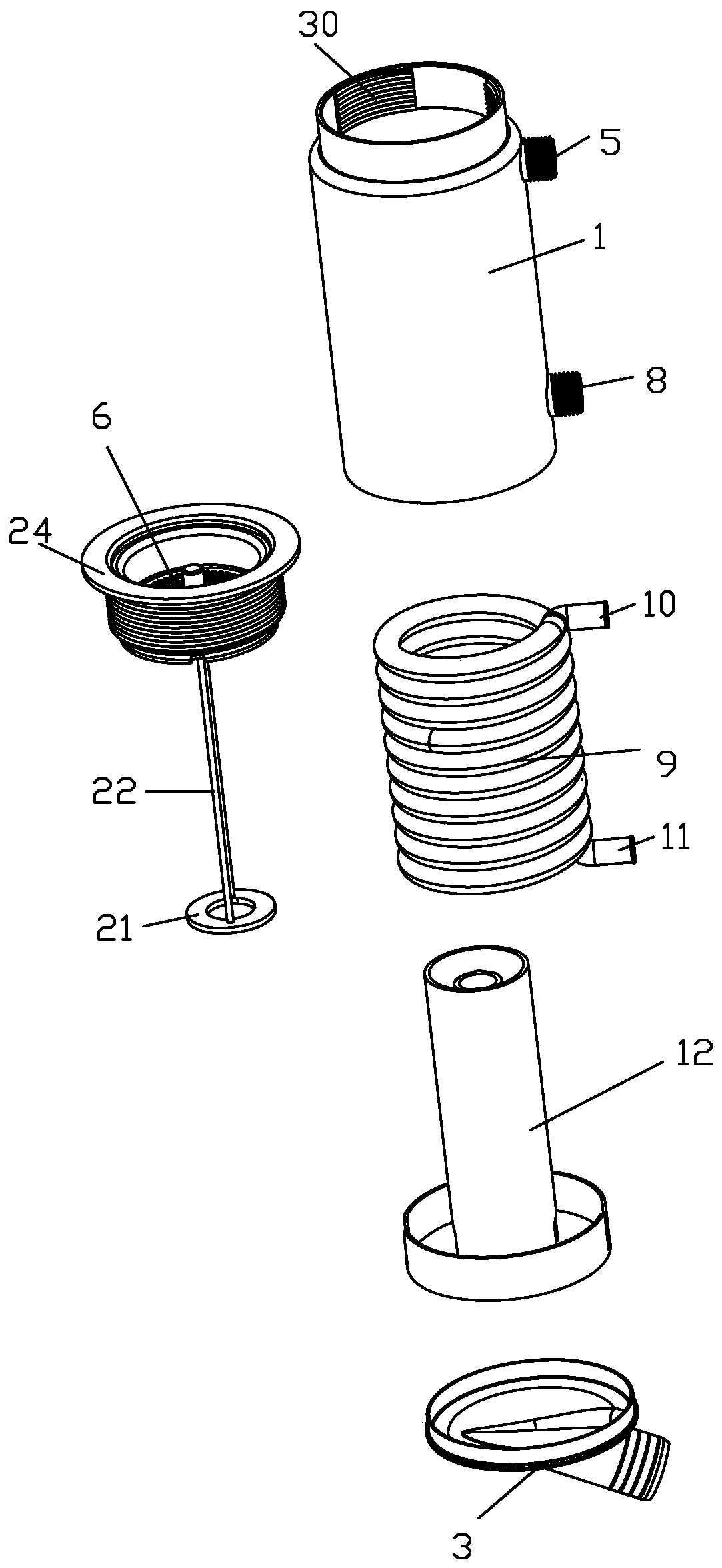

[0025] A high-efficiency energy-saving heat exchange device, which includes a main shell 1, the upper part of the main shell 1 is provided with a waste water inlet 2, a bottom cover 3 is fixed below the main shell, the lower part of the main shell 1 is provided with a waste water outlet 4, and the main shell The body 1 is also provided with a hot water outlet 5 and a cold water inlet 8. The upper part of the main housing 1 is also provided with a filter device 6 communicated with the waste water inlet 2. The filter device 6 is provided with a shroud 7, and the lower part of the main housing 1 Also be provided with hot water outlet 8, also be provided with bellows 9 in main housing 1, the bellows outlet 10 of bellows 9 communicates with hot water outlet 5, the bellows inlet 11 of bellows 9 communicates with cold water inlet 8, main The shell 1 is also provided with a self-pressurized heat exchange assembly 12, and the bellows 9 is arranged in the self-pressurized heat exchange a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com