Equipment fault alarm method and device

A technology for equipment failure and equipment to be tested, applied in alarms, measuring devices, instruments, etc., can solve problems such as low fault alarm accuracy, achieve high fault alarm accuracy, improve fault alarm accuracy, and be prone to early failures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

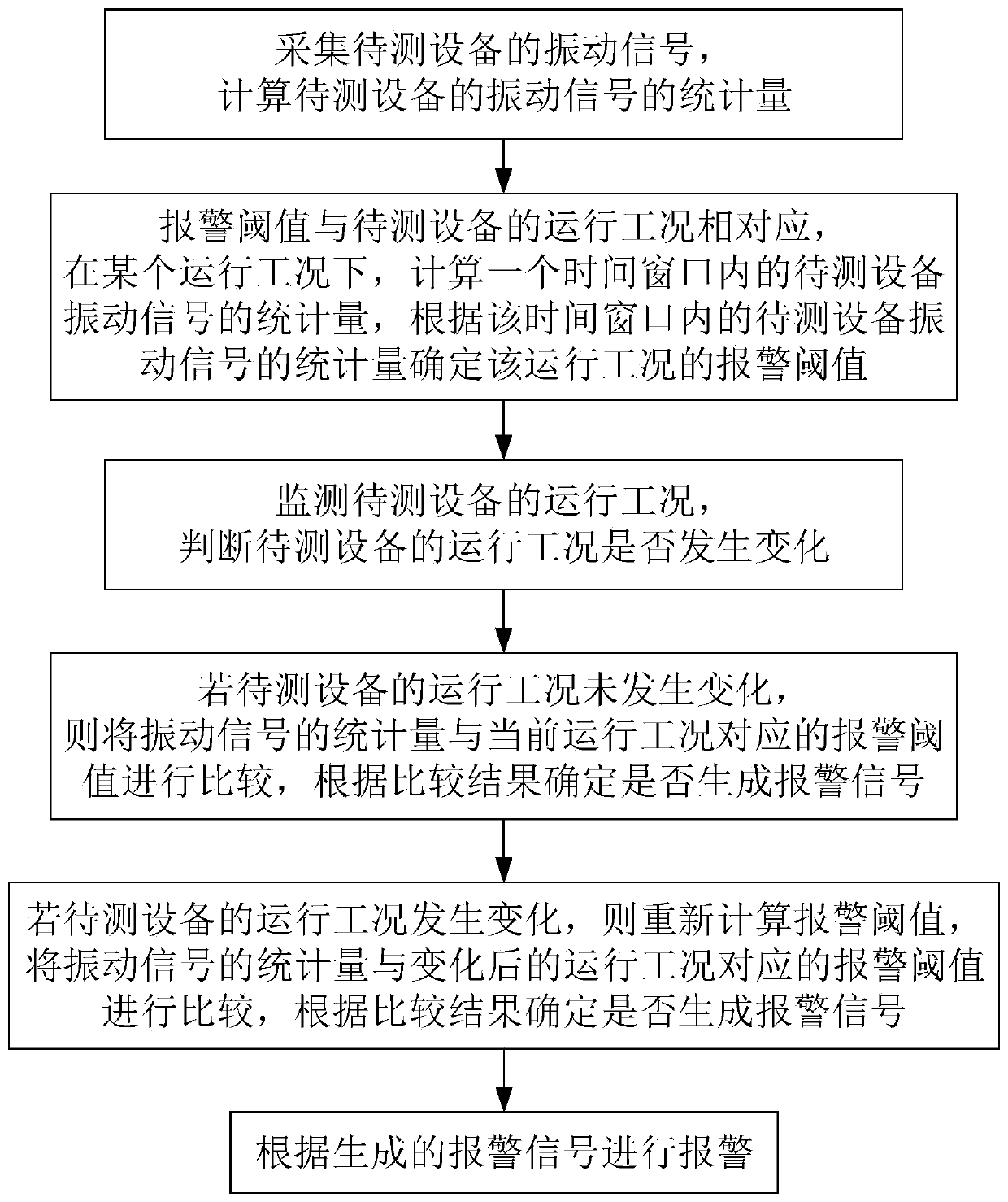

[0031] Embodiment 1 relates to an embodiment of an equipment failure alarm method and an embodiment of an equipment failure alarm device.

[0032] In this embodiment, when an equipment failure alarm is performed, an acceleration sensor is installed on the bearing or gear of the equipment to be tested. Under the condition that the sampling theorem is satisfied, the acceleration sensor is used to collect the vibration signal of the equipment to be tested, and the collected vibration signal of the equipment to be tested is The equipment failure alarm device processes the received vibration signal of the equipment under test to realize the equipment failure alarm method of this embodiment, and then realize the equipment failure alarm.

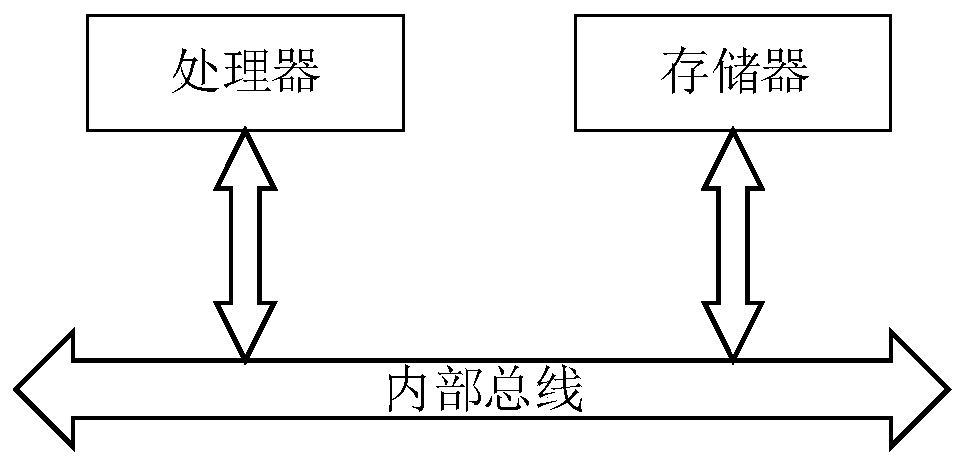

[0033] The equipment failure alarm device of this embodiment is as follows: figure 1 As shown, the device includes a processor and a memory, and the processor executes the computer program stored in the memory to implement the equipment failure ala...

Embodiment approach 2

[0062] Embodiment 2 relates to an embodiment of an equipment failure alarm method and an embodiment of an equipment failure alarm device.

[0063] The structure of the equipment failure alarm device in this embodiment is the same as that in Embodiment 1, the difference lies in that the equipment failure alarm method that can be realized by the equipment failure alarm device in this embodiment is different from that in Embodiment 1.

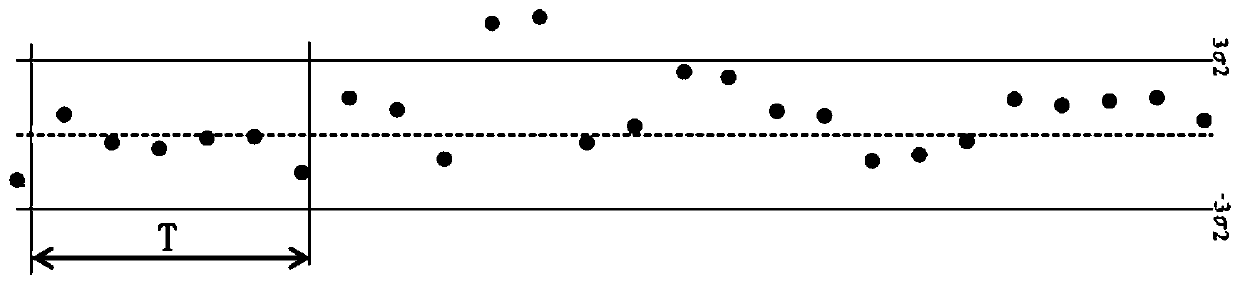

[0064] The equipment failure alarm method of this embodiment differs from Embodiment 1 only in that: when the operating condition of the equipment under test changes, the time window is also updated, and the alarm threshold is recalculated on the updated time window. For example, if the operating condition of the equipment under test changes from a stable condition to a variable speed condition, the alarm threshold is recalculated on the time window corresponding to the variable speed condition.

[0065] As shown in Table 1, the operating conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com