Automatic punching die device

An automatic punching and mold technology, applied in the field of punching processing, can solve the problems of low efficiency and low precision, and achieve the effect of high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

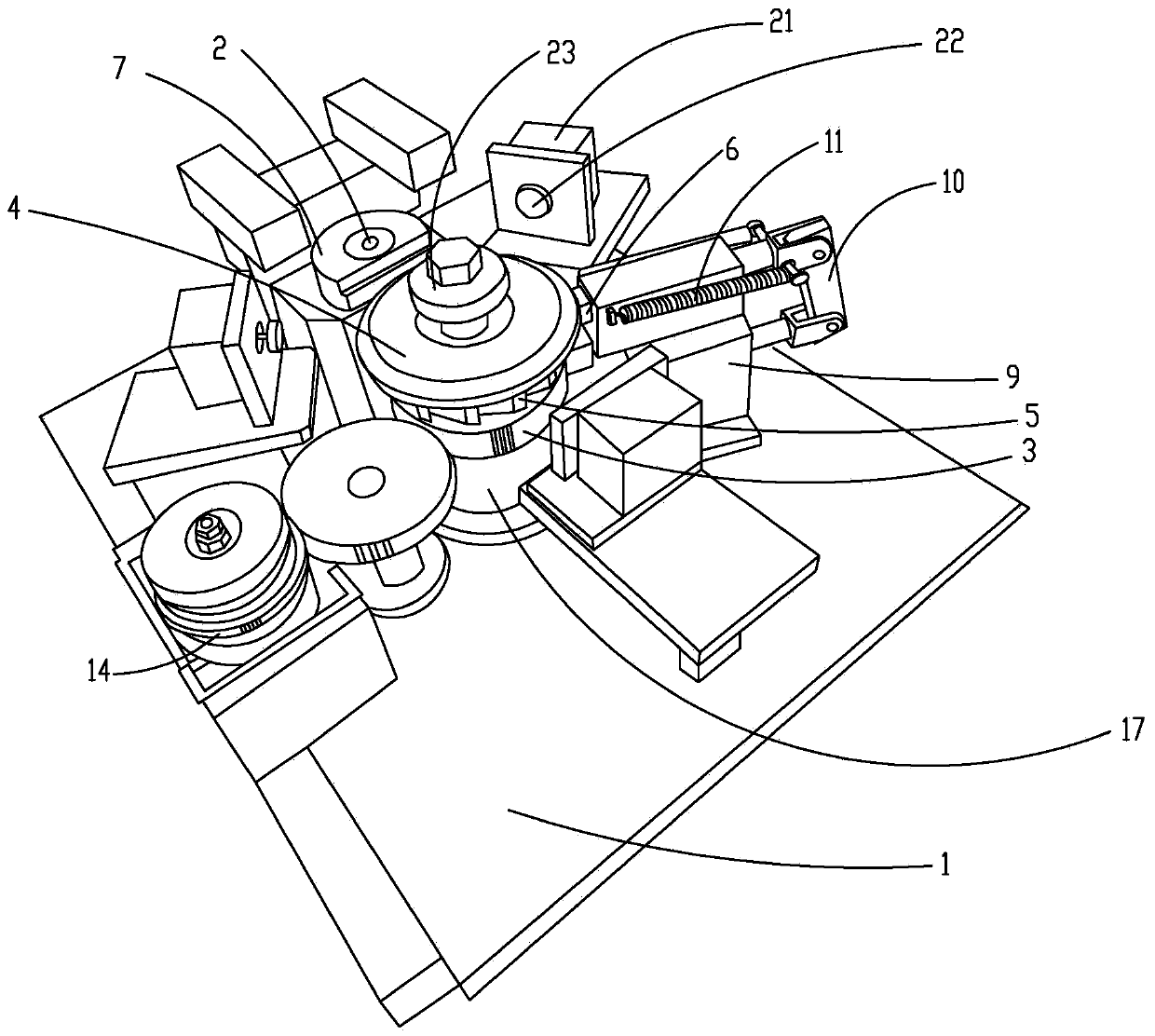

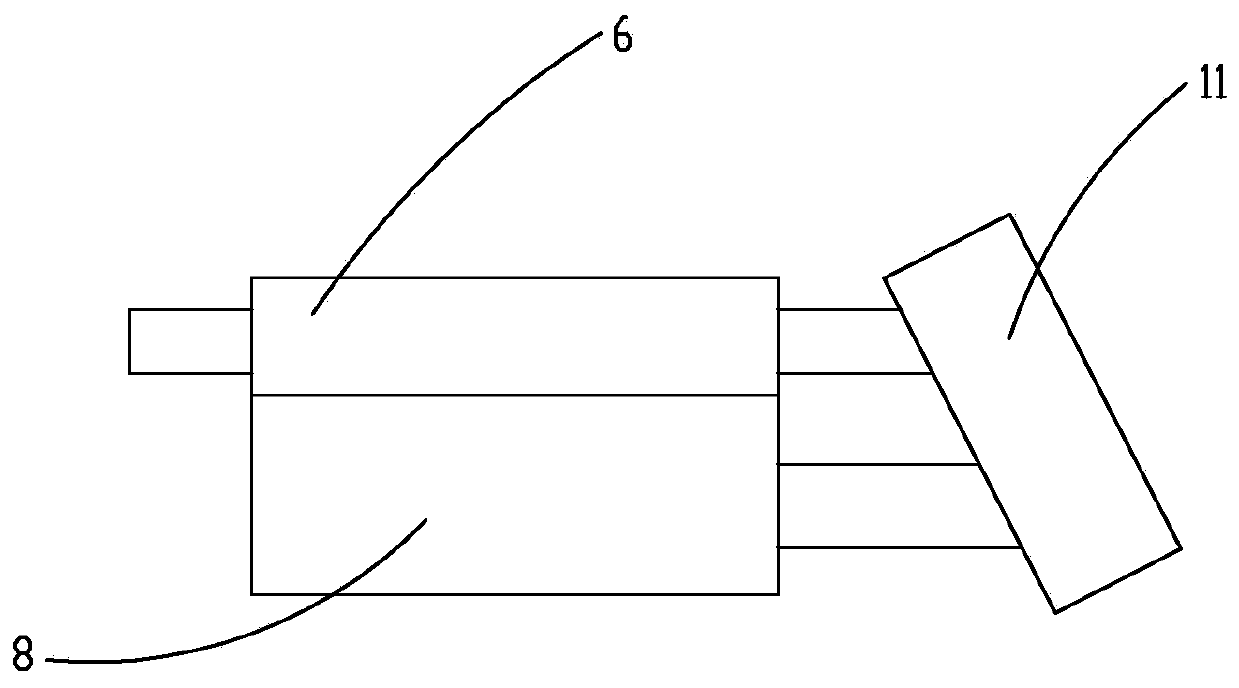

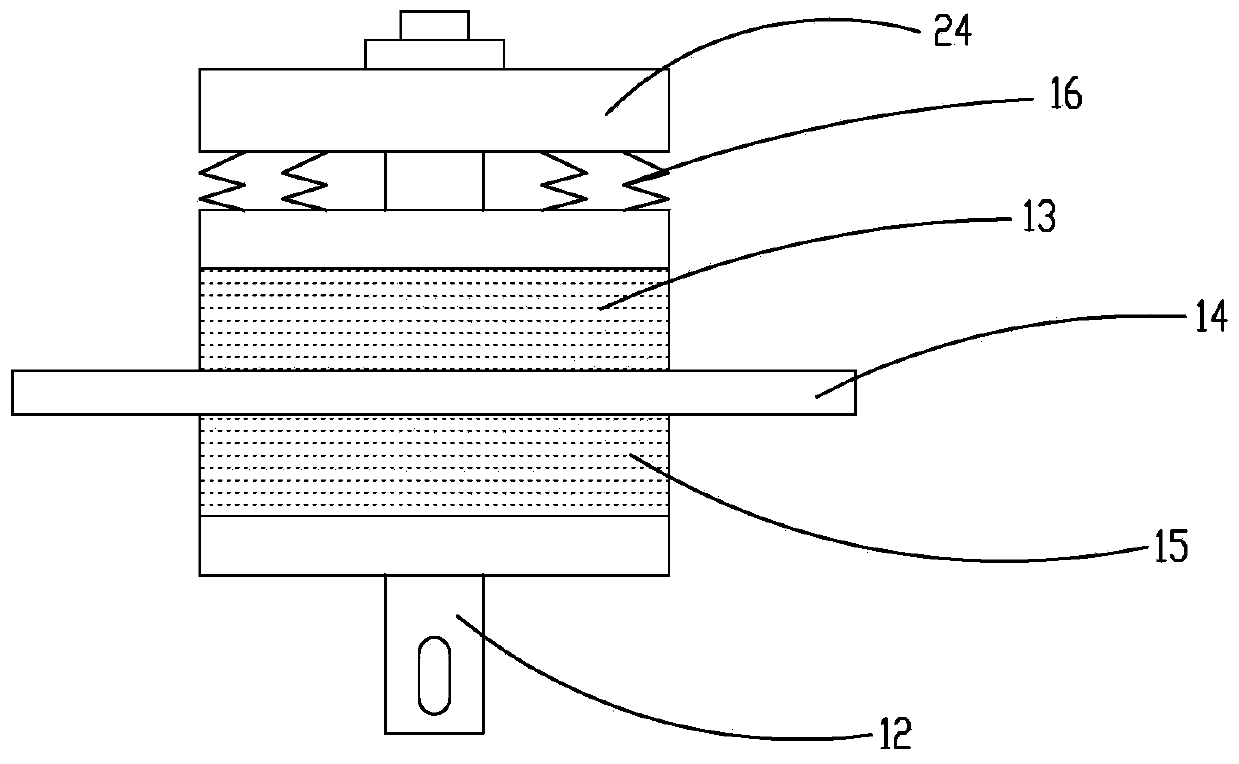

[0022] like Figure 1~5 The embodiment of the present invention shown is an automatic punching die device, including a working platform 1, the working platform 1 is provided with a motor, a rotary oil cylinder, a positioning device and a stamping column 7, and the rotary oil cylinder is provided with a transmission gear 3, and the transmission gear 3 is fixed On the cylinder body of the rotary oil cylinder, the cylinder body and the transmission gear 3 rotate together. The motor and the transmission gear 3 are connected to drive the rotary oil cylinder to rotate. The top of the rotary oil cylinder is provided with a supporting tray 4 for placing workpieces. The rotation of the supporting tray 4 drives The workpiece rotates, and the bottom of the supporting tray 4 is provided with a ratchet 5. The positioning device includes a pawl block 6 that cooperates with the ratchet 5. The pawl block 6 can move to approach or move away from the ratchet 5. When the pawl block 6 is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com