Automotive interior trim atmosphere lamp assembly and manufacturing method thereof

A technology for automotive interiors and manufacturing methods, which is applied in the field of automotive interiors, and can solve problems such as unclear display of patterns, changes in light transmittance of ambient light shells, inconsistent light transmittance of light source refraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present application will be described in further detail below in conjunction with the accompanying drawings and embodiments.

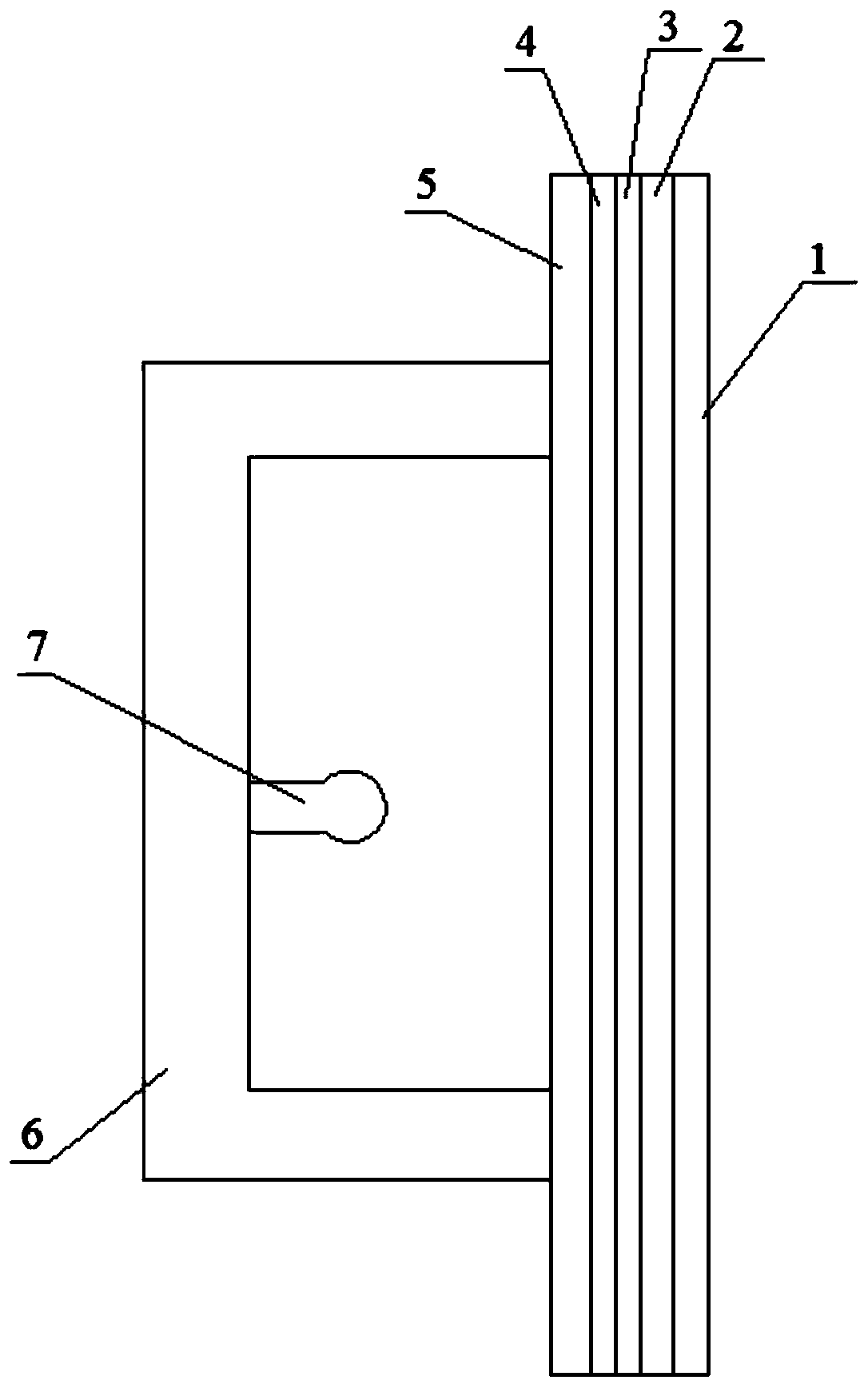

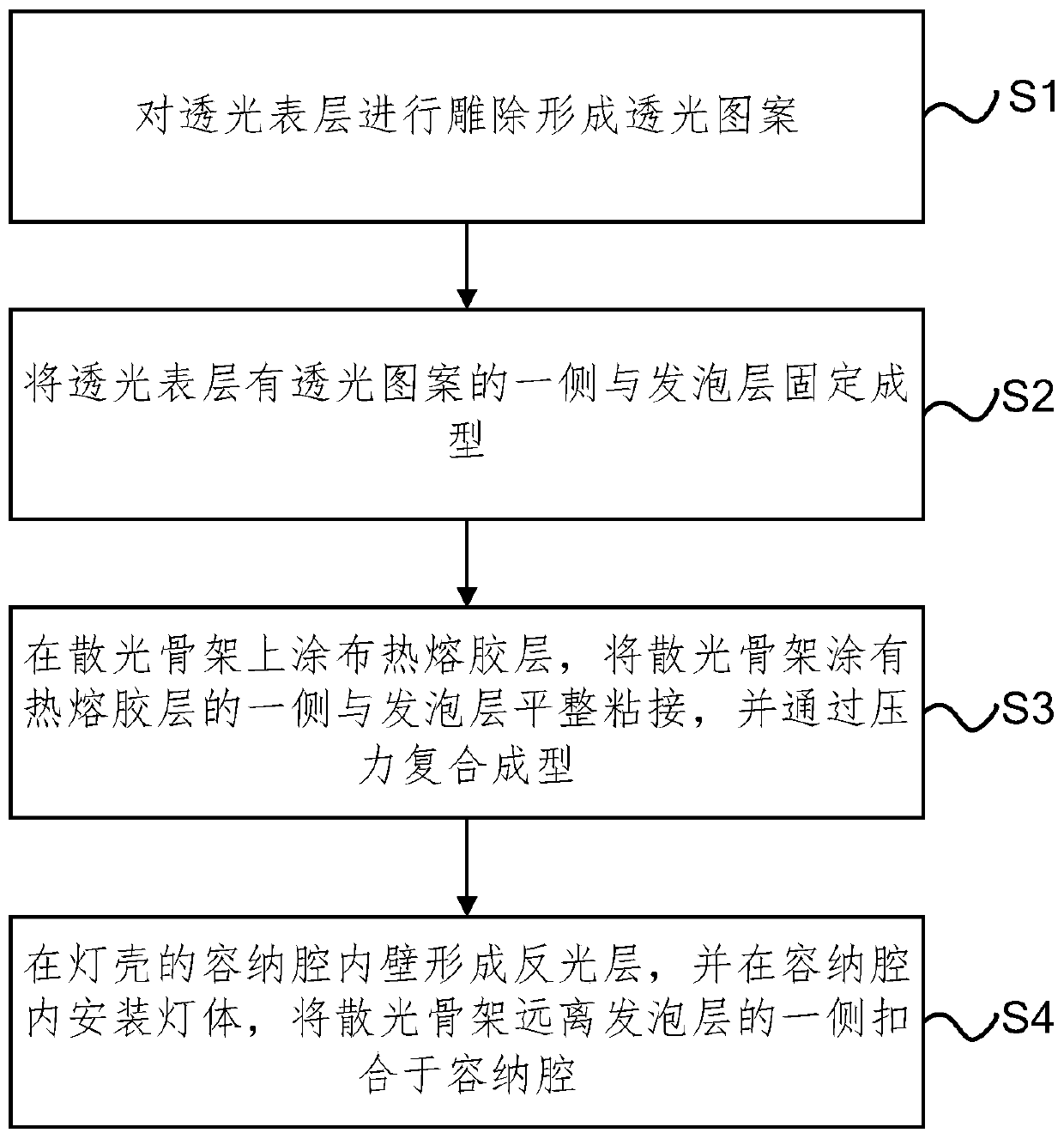

[0042] see figure 1 As shown, the present application provides an embodiment of an automotive interior ambient light assembly, which includes a light-transmitting surface layer 1 , a foam layer 3 , an astigmatism frame 5 , a lamp housing 6 and a lamp body 7 .

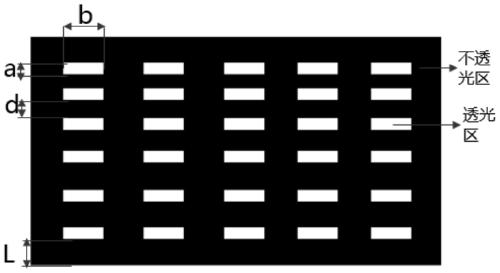

[0043] One side of the light-transmitting surface layer 1 is carved to form a light-transmitting pattern 2 . The foam layer 3 is arranged on the side of the light-transmitting surface layer 1 having the light-transmitting pattern 2 . The astigmatism framework 5 is evenly bonded to the side of the foam layer 3 away from the light-transmitting surface layer 1 through the hot melt adhesive layer 4 , and the astigmatism framework 5 is used to uniformly scatter received light. The light-transmitting surface of the atmosphere lamp is formed by the light-transmitting surface layer 1 , the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com