A Common Rail Injector Sensitive Fault Feature Extraction Method Based on Composite Hierarchical Discrete Entropy Chde and Pairwise Proximity Pwfp

A common rail injector and fault feature technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of difficult and low extraction accuracy of common rail injector fault features, and achieve good fault diagnosis results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in more detail below in conjunction with the accompanying drawings:

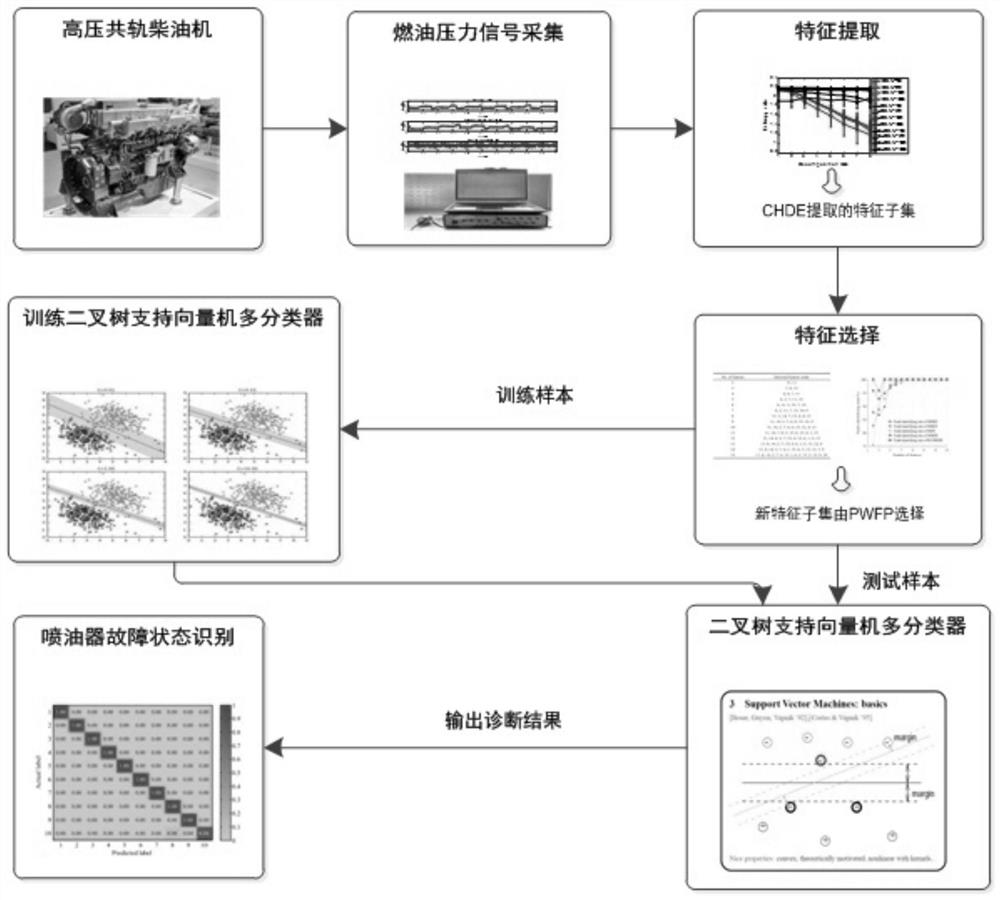

[0041] combine Figure 1-5 , a common rail injector sensitive fault feature extraction method based on CHDE and PWFP, including the following steps:

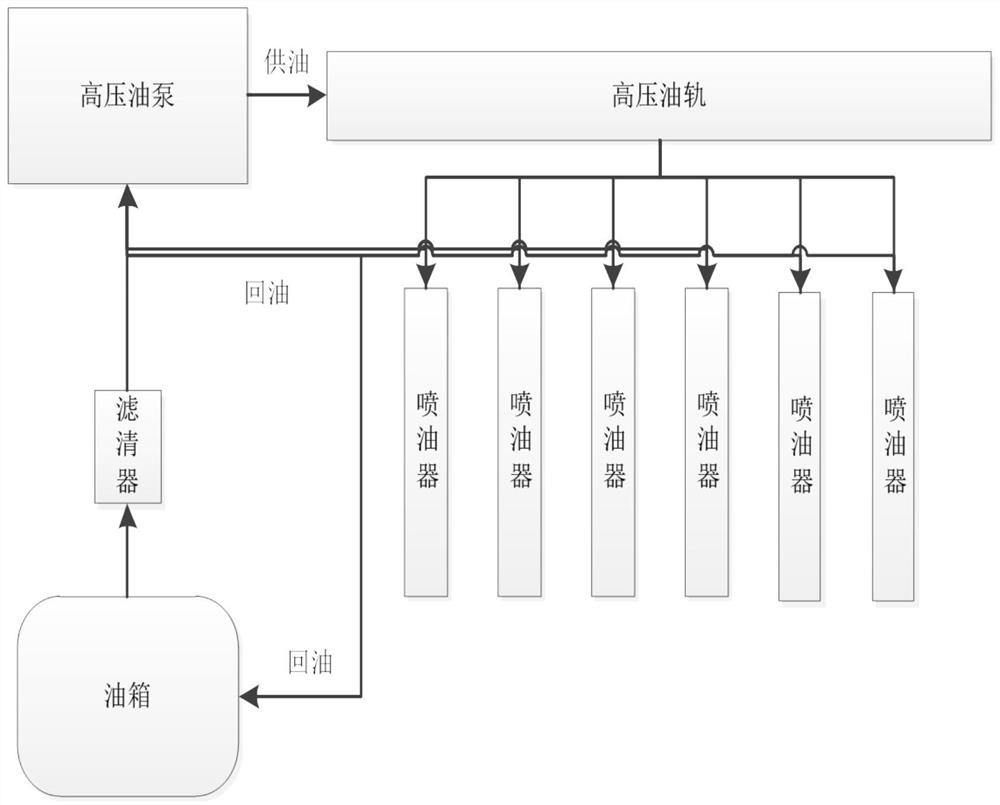

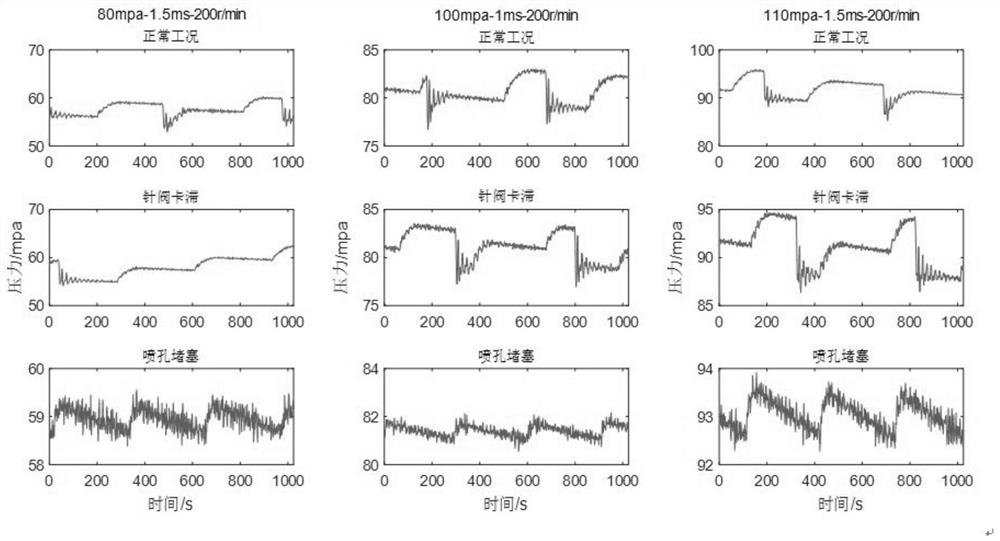

[0042] S1. Use a high-precision pressure sensor to collect the fuel pressure fluctuation signal of the high-pressure fuel pipe, and divide the collected signal into a training signal and a test signal;

[0043] S2. Calculate the composite hierarchical discrete entropy of the training signal and the test signal respectively;

[0044] S3. Calculate the proximity between discrete entropies at each level, and score with the proximity as a reference. The scores are arranged in ascending order. The lower the score, the more sensitive the fault feature is;

[0045] S4. Select the top-ranked composite hierarchical discrete entropy in the training sample to form a subset of feature vectors, and input the binary tree supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com