Engine fault detection method, system, storage medium and equipment

A fault detection and engine technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of parameter fitting error, difficulty in detecting unknown abnormal engine faults, and decline in diagnostic accuracy, and achieve strong adaptability performance, good fault diagnosis ability, and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

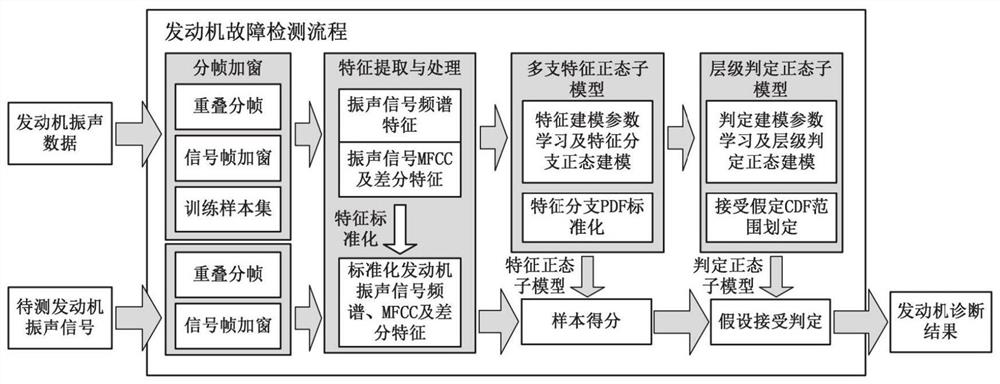

[0046] like Figure 1-5 As shown, the engine failure detection method includes the following steps:

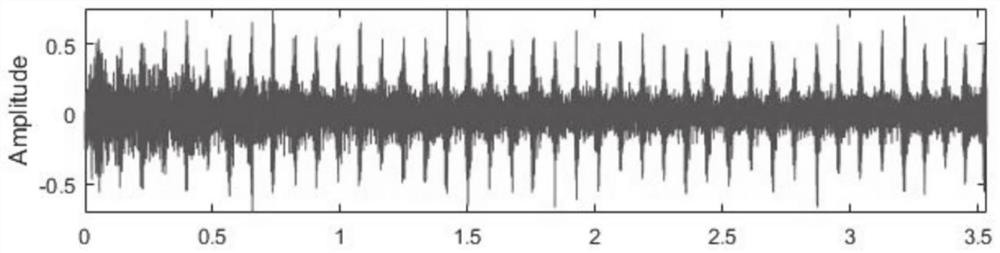

[0047] Obtain the engine vibro-acoustic signal data, and intercept the continuous vibro-acoustic signal into equal-length and overlapping signal frames;

[0048] Obtain the frequency characteristics, Mel cepstral coefficient characteristics and difference characteristics of the vibroacoustic signal based on the signal frame;

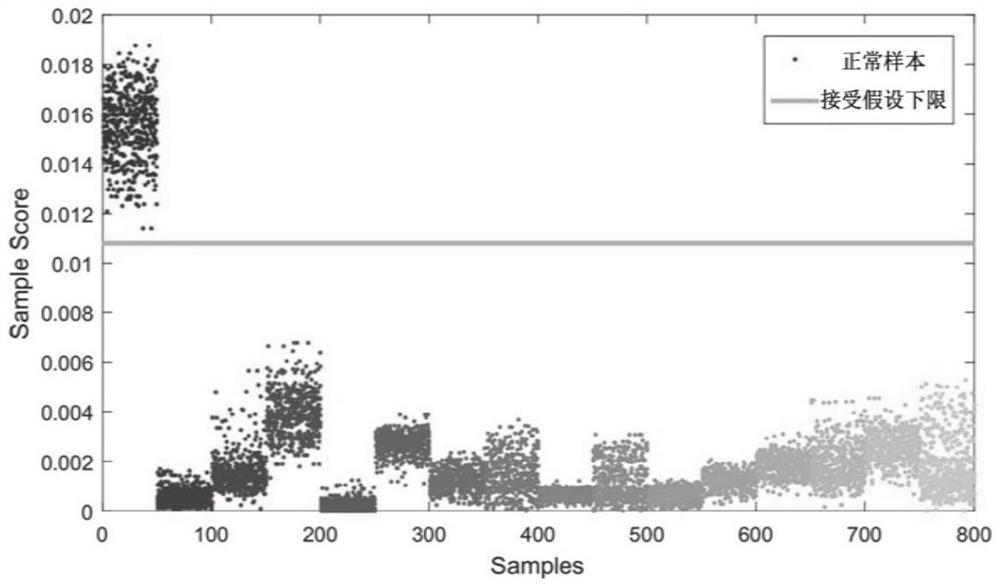

[0049] According to the spectral features, Mel cepstral coefficient features and differential features, the multi-branch feature normal sub-model is constructed; each branch sub-model in the multi-branch feature normal sub-model is standardized to obtain samples for known fault type samples Score, the larger the value of the sample score, the more likely it belongs to this type of fault type, and vice versa, the less likely it belongs to this type of fault type;

[0050] Construct a hierarchical decision normal submodel based on sample scores;

[0051...

Embodiment 2

[0105] This embodiment provides a system for realizing the above detection method, including:

[0106] The data acquisition module is configured to: acquire engine vibro-acoustic signal data, intercept continuous vibro-acoustic signals into equal-length and overlapping signal frames; acquire frequency characteristics, Mel cepstral coefficient features and Differential features;

[0107] The model construction module is configured to: construct a multi-branch feature normal submodel according to the spectral feature, the Mel cepstral coefficient feature and the difference feature; standardize each branch sub-model in the multi-branch feature normal sub-model, and obtain Sample score for samples of known fault types; construct a hierarchical judgment normal submodel based on the sample score;

[0108] The judging module is configured to: for all fault types, use the multi-branch characteristic normal sub-model and the hierarchical normal sub-model to construct a multi-branch le...

Embodiment 3

[0111] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the steps in the engine failure detection method proposed in the first embodiment above are implemented.

[0112] In the engine fault detection method implemented in this embodiment, the working state and fault type of the engine in the actual engine inspection workshop environment can be accurately detected, and abnormal conditions can be reflected in time while almost no false detection occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com