Devices for pipeline jacking construction

A jacking and pipeline technology, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem that the jacking force cannot be completely transmitted, and achieve the effect of not being easily deformed and well supported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

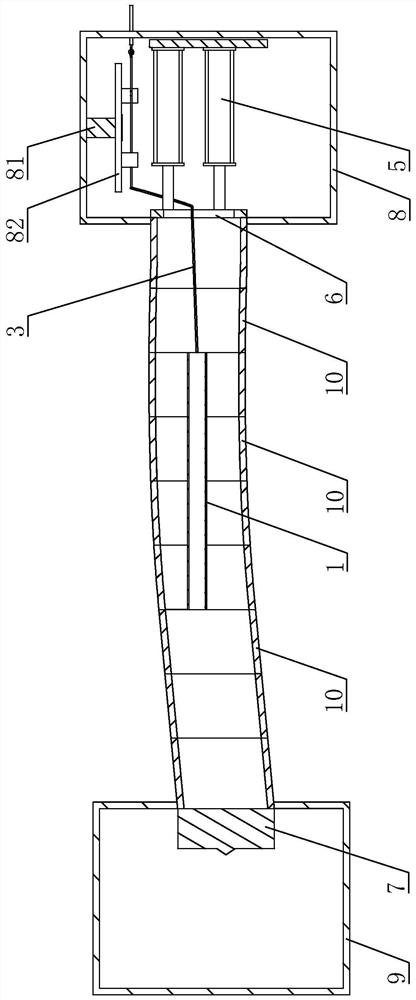

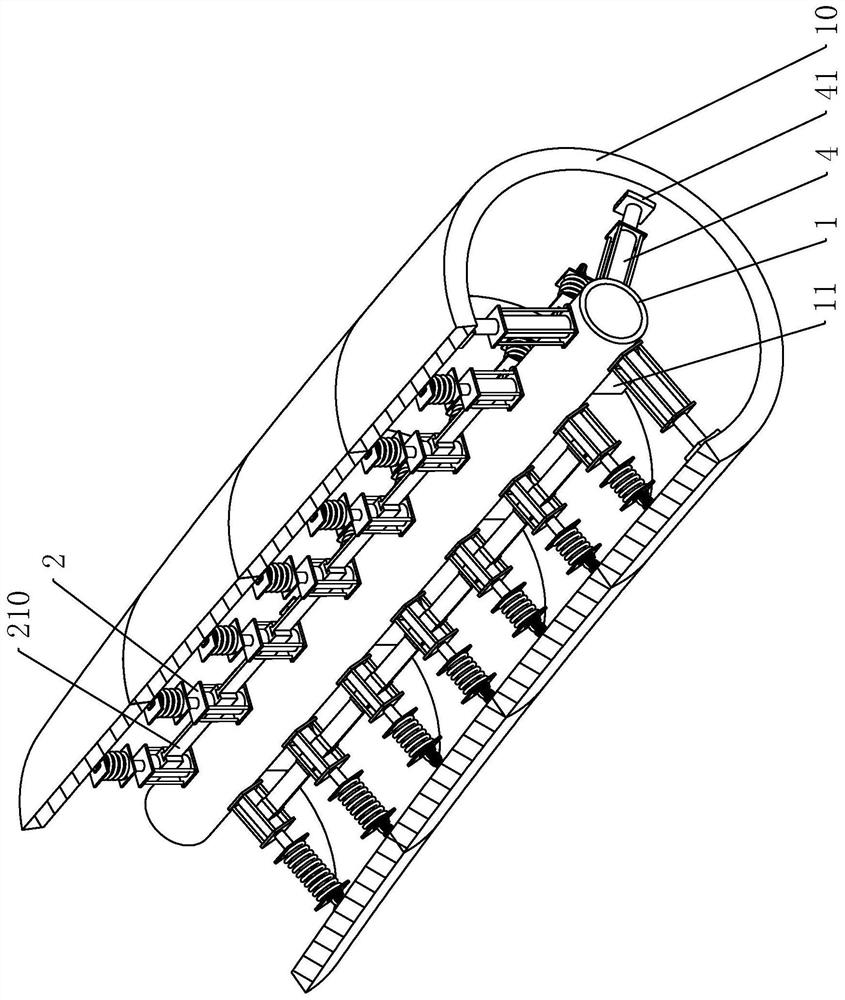

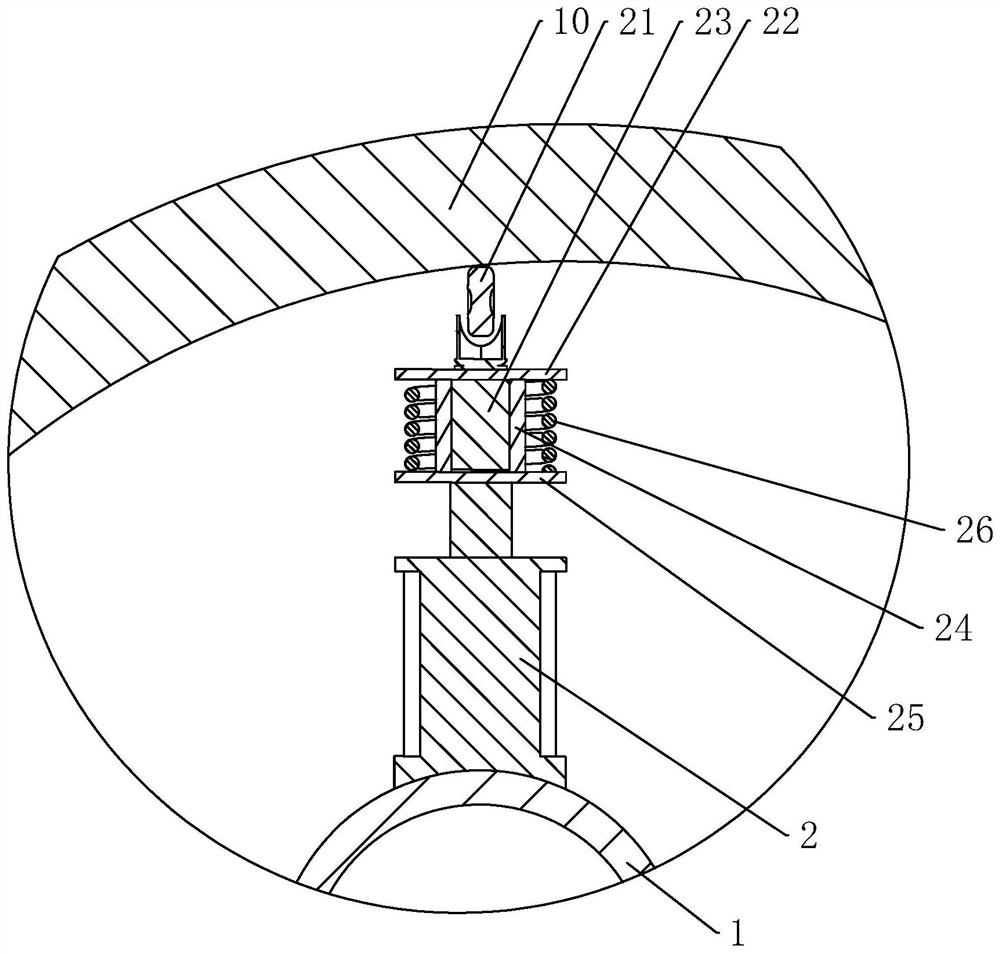

[0036] refer to figure 1, is a device for pipeline jacking construction disclosed by the present invention, including a jack 5, a jacking iron 6, a support rod 1 and a jacking head 7. Wherein, the jack 5 and the top iron 6 are arranged in the originating shaft 8, and the jack 5 offsets the pipe joint 10 through the top iron 6, and pushes the pipe joint 10 to the receiving shaft 9. The hollow support rod 1 is located in the pipeline of the curved section, and is used to maintain the extension track of the pipeline and make it difficult to deform. The jacking machine head 7 is arranged at the front end of the pipeline and offsets against the first pipe joint 10 .

[0037] refer to figure 1 , the end of the support rod 1 facing the origin shaft 8 is located in the straight pipe section 10, and the axis of the support rod 1 coincides with the pipe section 10, and the other parts of the support rod 1 are located in the three-section pipe corresponding to the curved pipe. Section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com