Multi-freedom-degree constraint auxiliary supporting device for reverse guided missile launching

An auxiliary support and degree of freedom technology, which is applied in the direction of launching devices, devices for preventing multi-way movement of goods, load handling devices, etc., can solve the problems of insufficient constraints on degrees of freedom, low firmness, and poor reliability, so as to improve the safety of product transportation Sexuality, reliable constraints, and the effect of realizing multi-degree-of-freedom full constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

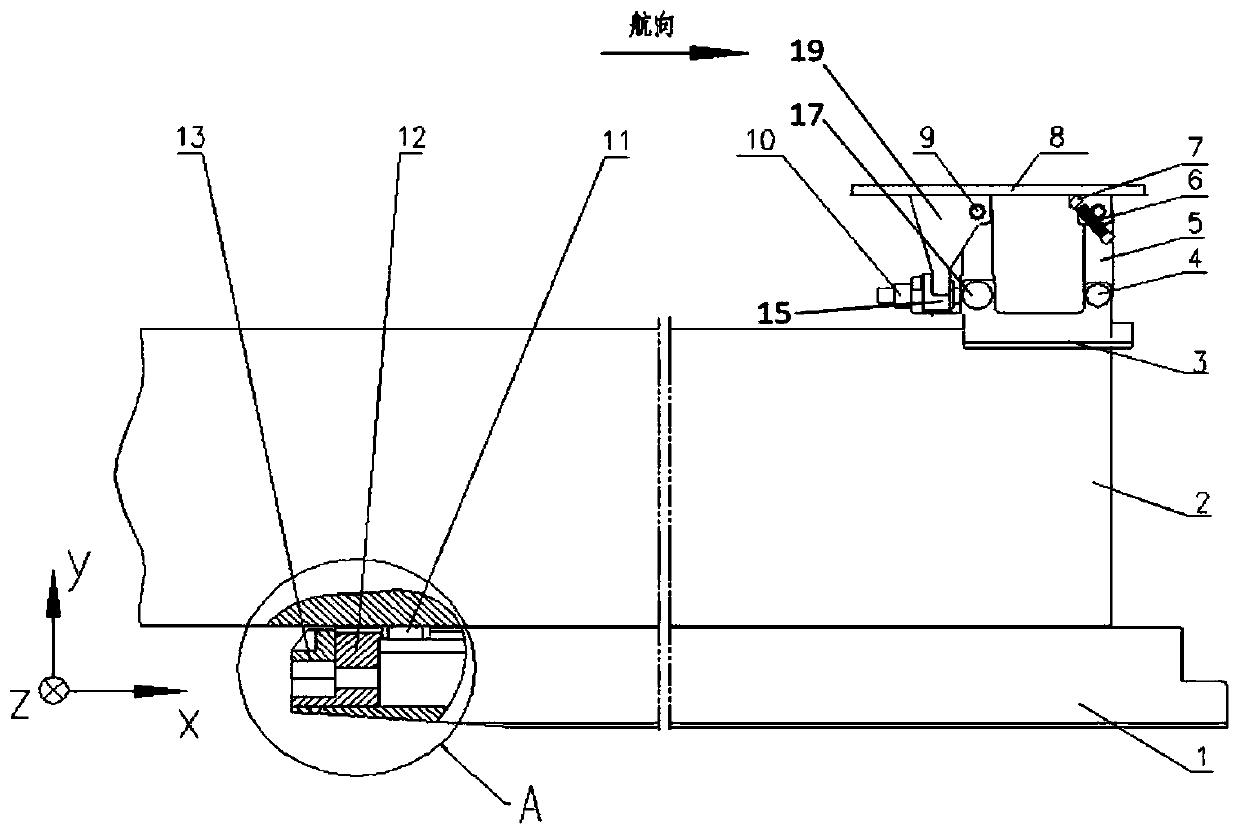

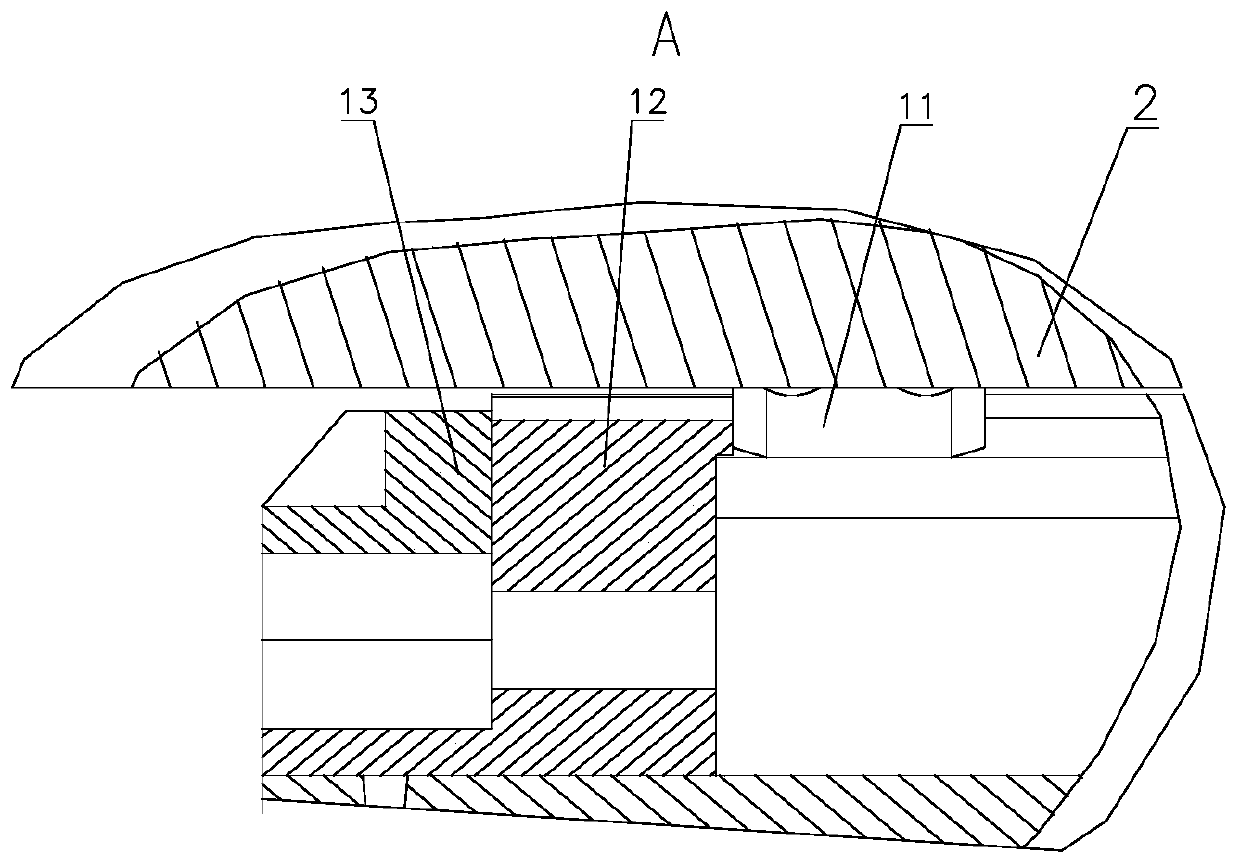

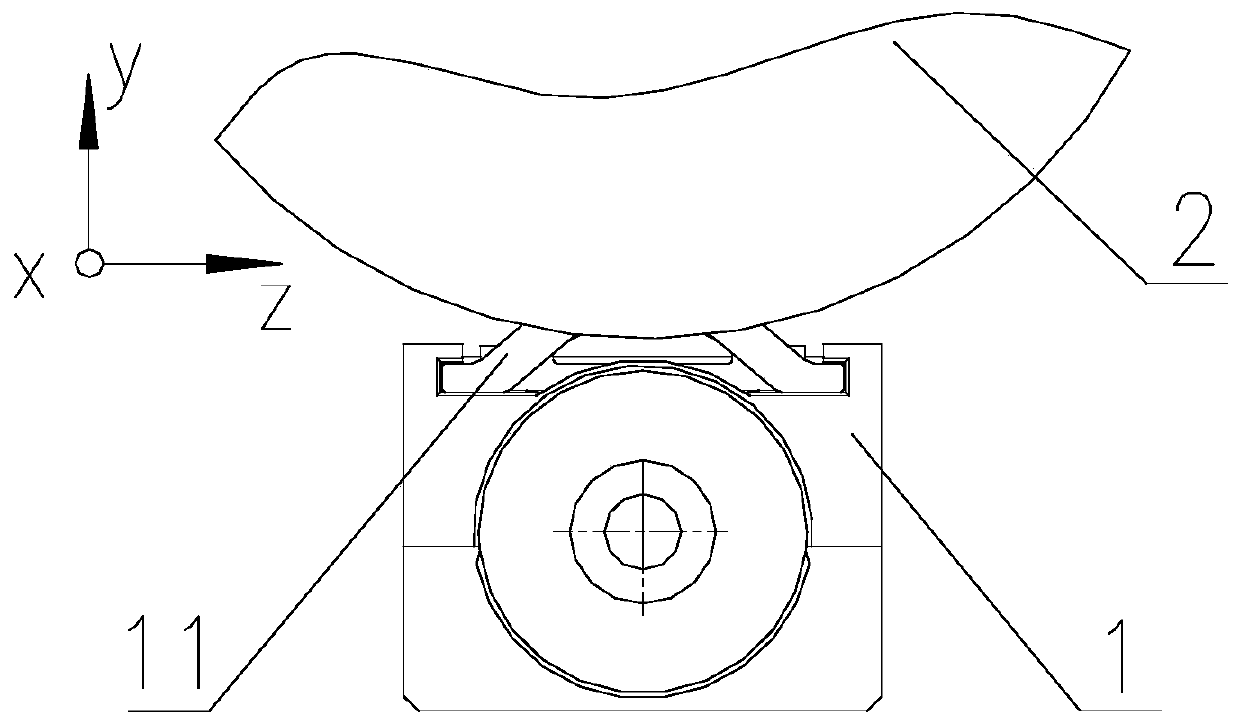

[0040] like Figure 1~6 Shown is a multi-degree-of-freedom restraint auxiliary support device for reverse launching missiles provided by the present invention. The parallelogram mechanism also includes a connecting piece 19, and the connecting piece 19 is fastened on the bottom plate 8. On the connecting piece 19, A pressing block 15 is provided for fastening.

Embodiment 2

[0042] like Figure 1~6 Shown is a multi-degree-of-freedom restraint auxiliary support device for reverse launching missiles provided by the present invention. The parallelogram mechanism also includes an explosive bolt 10, and one end of the explosive bolt 10 is installed on the connecting piece 19 and the pressure block 15. , and the other end is sleeved on the third rotating shaft 17 . There are semicircular grooves on the connecting piece 19 and the briquetting block 15, and two semicircular grooves form a cylindrical hole. In the semicircular groove, the explosive bolt 10 is fixed.

Embodiment 3

[0044] like Figure 1~6Shown is a reverse launch missile multi-degree-of-freedom restraint auxiliary support device provided by the present invention, which also includes a pair of tension springs 6, and the pair of tension springs 6 are correspondingly arranged at both ends of the second rotating shaft 16; One end of the tension spring 6 is connected to the second connecting rod 5 , and the other end is connected to the bottom plate 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com