Combined supporting and absorbing device and low-temperature multilayer heat insulating vessel having same

An adsorption device and a multi-layer heat insulation technology are applied in the direction of pressure vessels, container filling methods, and container discharge methods, which can solve the problems of reducing the volume of the inner container, not easy to maintain the vacuum degree of the interlayer, and increasing the external dimension, so as to maintain The effect of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

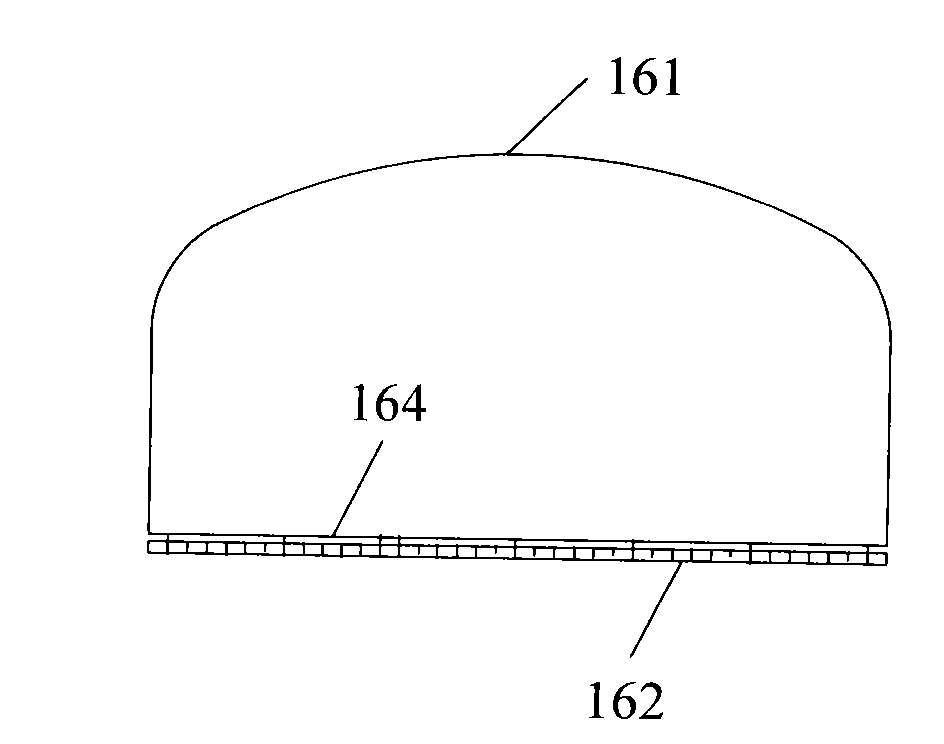

[0038] Such as Figure 4 and Figure 5 As shown, the present invention provides a combined support and adsorption device 30, which includes: a cover body 31 with one end closed and the other end open; A receiving space 39 is defined between the plates 32 . The baffle 32 is a porous structure and has an opening 321 thereon, so that one end (first end) 341 of the supporting structure 34 can pass through the opening 321 into the inside of the cover body 31 , that is, into the accommodating space 39 . The other end (second end) 342 of the support structure 34 is located outside the cover body 31 . The support structure 34 is preferably made of fiberglass material.

[0039] In the accommodation space 39 , the cryogenic adsorbent 90 is filled around the support structure 34 . For example, a commonly used cryogenic adsorbent is in the form of small cylindrical particles with a diameter of about 2mm and a length of 3-6mm. The porous structure of the baffle 32 allows the accommoda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com