Experimental device for adjustable frequency and phase unsteady flow control based on rotating slot grid

A technology for unsteady flow and control experiments, applied in pump control, measuring devices, aerodynamic tests, etc., to achieve the effects of small volume and weight, improved boosting capacity, and adjustable phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

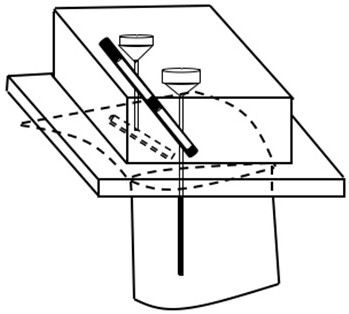

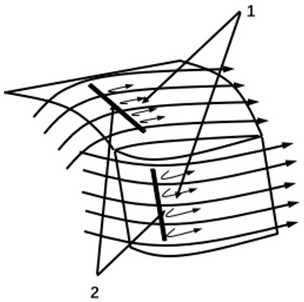

Embodiment 1

[0041] Using the above-mentioned inventive device, research on the unsteady control of the corner separation flow of the double-sided diffuser channel has been carried out, such as Figure 5 , There is a 1mm jet slit at the initial separation position of the two expansion sections. Among them, the pipeline of bleed air is intersected with a rotating slot grid driven by a high-speed micro motor. There are a total of 6 slots distributed on the rotating slot grid, of which the upper part of the rotating slot grid (including 3 slots) and The intersecting air channel leads to the jet outlet on one side of the expansion channel, and the lower half of the intersecting air channel is connected to the jet outlet on the other side. The micro motor drives the rotating slit grid to rotate to generate periodic opening and closing flow. The path, and then form a periodic pulse jet, and control the phase of the jet in the corner area by designing the staggered positions of the distributed sl...

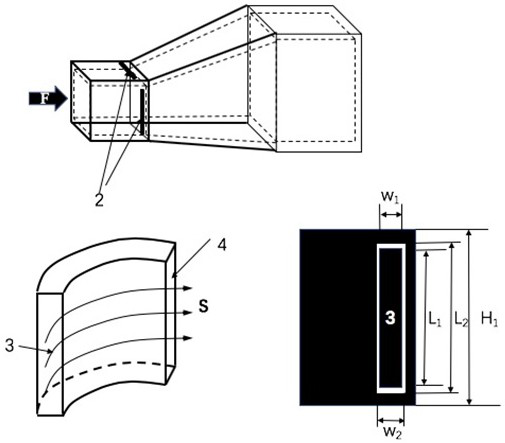

Embodiment 2

[0043] Using the above-mentioned inventive device, the research on unsteady control of the separation flow in the corner area of the double-sided diffuser channel with the different number of openings of the slit grid was carried out at the same time, and a jet slit of 1 mm was also opened at the initial separation position of the two expansion sections. The pipeline of the same bleed air is intersected with a rotating slit grid driven by a high-speed micro-motor. The difference is that three slits are used in the upper part, and two slits are used in the lower part, in which the upper part of the rotating slit grid (including 3 slits) intersects with the air channel leading to the jet outlet on one side of the expansion channel. The air path intersected with the lower part (including 2 slits) is connected to the jet outlet on the other side, and the micro motor drives the rotating slit grid to rotate to generate periodic opening and closing flow paths, thereby forming period...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com