A heat exchange structure and heat exchange control method

A heat exchange structure and control unit technology, applied in the field of heat exchange, can solve the problems of battery life, rapid temperature rise, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

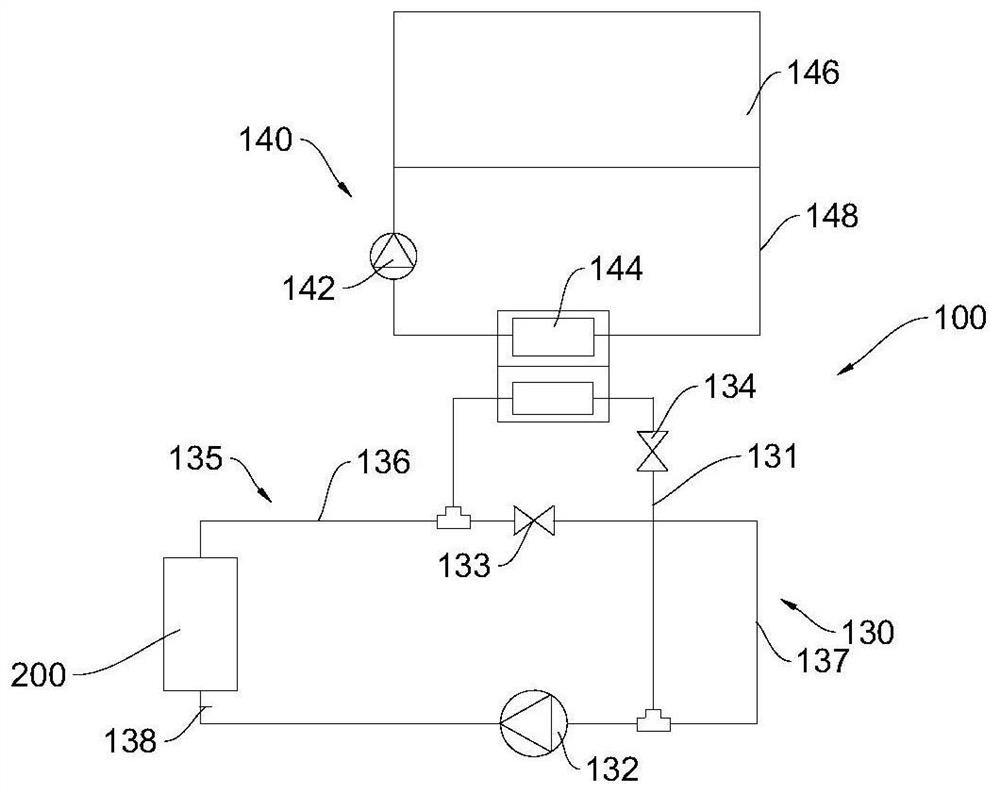

[0042] Please refer to figure 1 and figure 2 , this embodiment provides a heat exchange structure 100, the heat exchange structure 100 provided by this embodiment is mainly used for heat exchange of the product 200, the heat exchange structure 100 provided by this embodiment can ensure that the product 200 as a whole can be at a stable temperature Within the interval, it is safe and reliable, prolonging the service life of the product 200.

[0043] The product 200 is mainly a structure that requires heat dissipation, such as a battery.

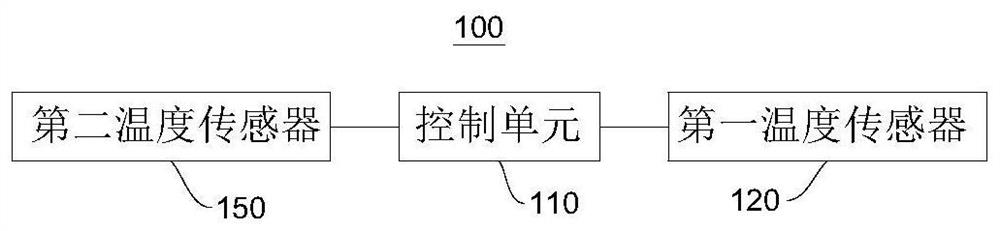

[0044] In this embodiment, the heat exchange structure 100 includes: a control unit 110, a first temperature sensor 120, a heat exchange assembly 140 and a circulation assembly 130, and the circulation assembly 130 is used to connect with the product 200;

[0045] The heat exchange component 140 communicates with the circulation component 130, and is used to exchange heat for the heat exchange medium in the circulation component 130;

[00...

no. 2 example

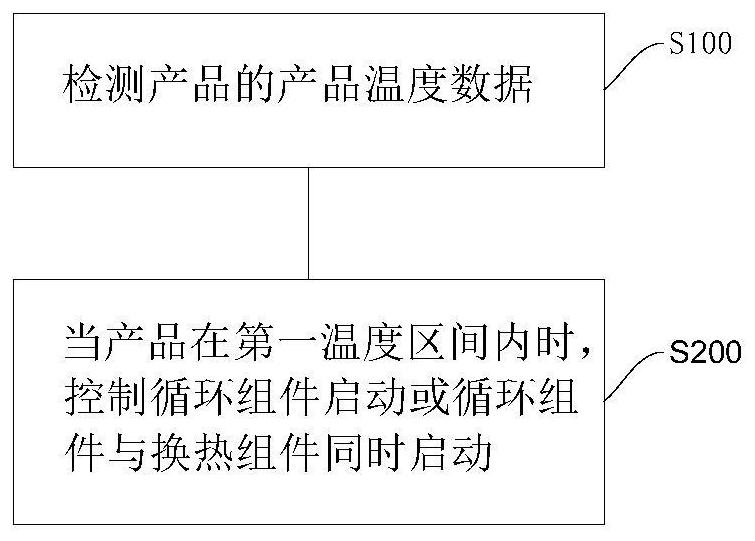

[0086] see image 3 , this embodiment provides a heat exchange control method, the heat exchange control method provided by this embodiment is mainly used for heat exchange of the product 200, the heat exchange structure 100 provided by this embodiment can ensure a stable temperature for the product 200 as a whole, Safe and reliable, prolonging the service life of the product 200.

[0087] The heat exchange control method provided in this embodiment is implemented based on the heat exchange structure 100 provided in the first embodiment, and the heat exchange structure 100 provided in the first embodiment is used to exchange heat for a product 200 . For brief description, the first embodiment may be referred to for the parts not mentioned in this embodiment.

[0088] Specific steps are as follows:

[0089] Step S100 , detecting product temperature data of the product 200 .

[0090] Step S200 , when the product 200 is within the first temperature range, control the cycle com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com