Feeding robot of a silkworm egg breeding tower

A robot and material feeding technology, which is applied in the field of bioengineering to achieve the effect of saving manpower, improving work efficiency and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

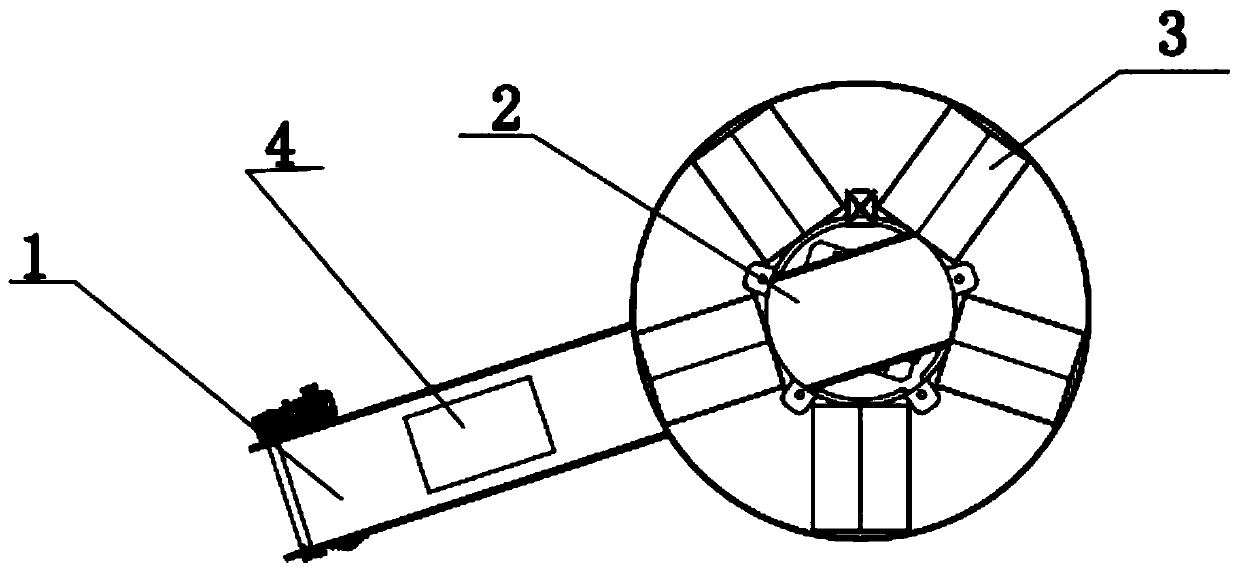

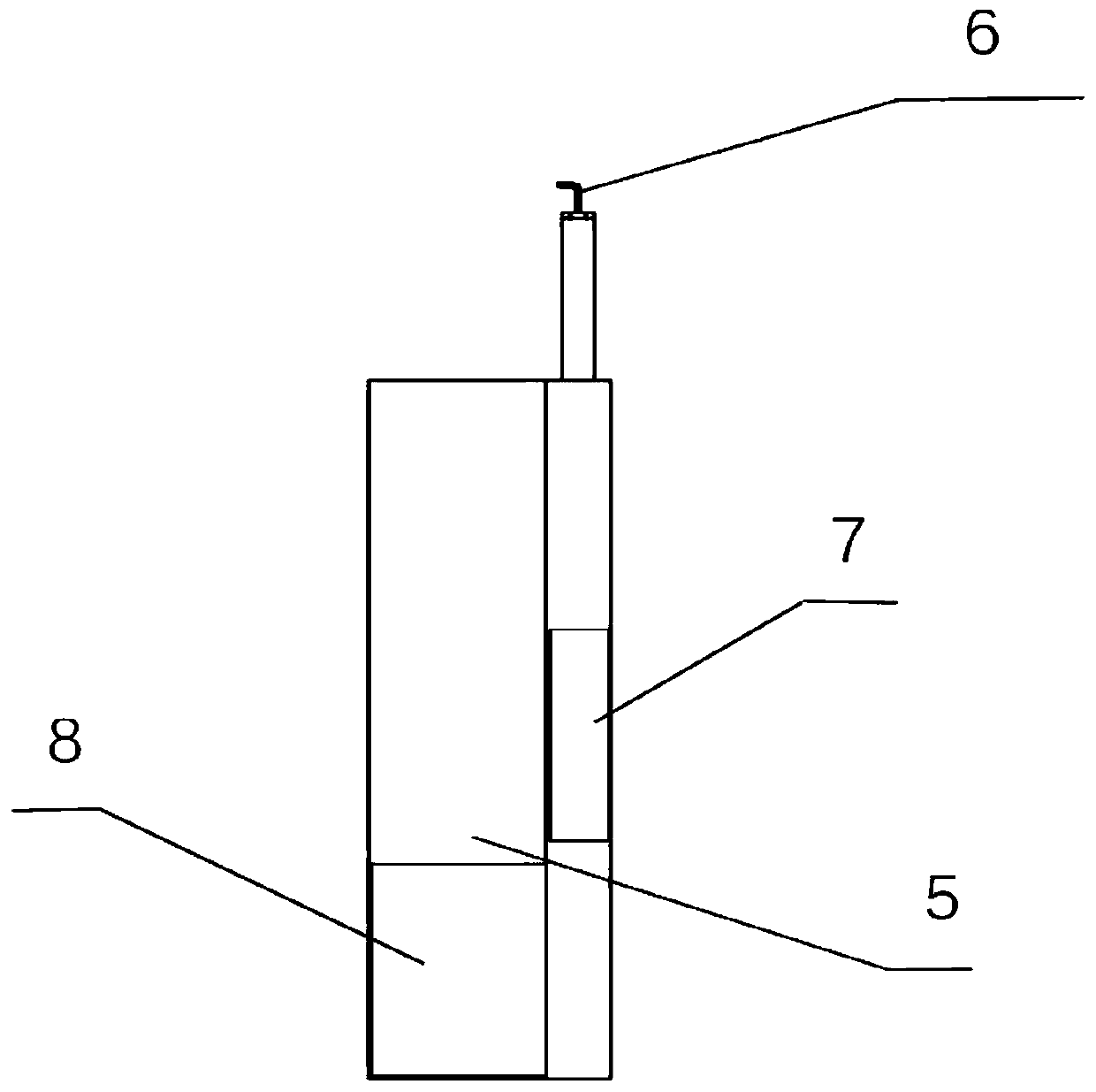

[0014] Such as figure 1 , figure 2 As shown, the silkworm egg cultivation tower feeding robot provided by the present invention includes: a storage box 5 , a feeding head 6 , a feeding head retracting device 7 and a control device 8 .

[0015] The storage box 5 has a large capacity, and can be loaded with the feeding head 6 while storing food.

[0016] Described feeding head 6 is made up of 10 or more small nozzles, and each small nozzle can spread out food, realizes spreading food evenly.

[0017] The material head retracting device 7 can push out the material head after the feeding robot of the silkworm egg cultivation tower reaches the designated position, so as to realize the extension and retraction of the material head 6 .

[0018] The food feeding head 6 can control the output of food to realize the feeding requirements of silkworms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com