High-speed electric hair drier

A technology for hair dryers and fans, applied in clothing, hairdressing equipment, hair drying devices, etc., can solve the problems of large fixed structure of motors, inconvenient portability and storage, large size of hair dryers, etc. Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

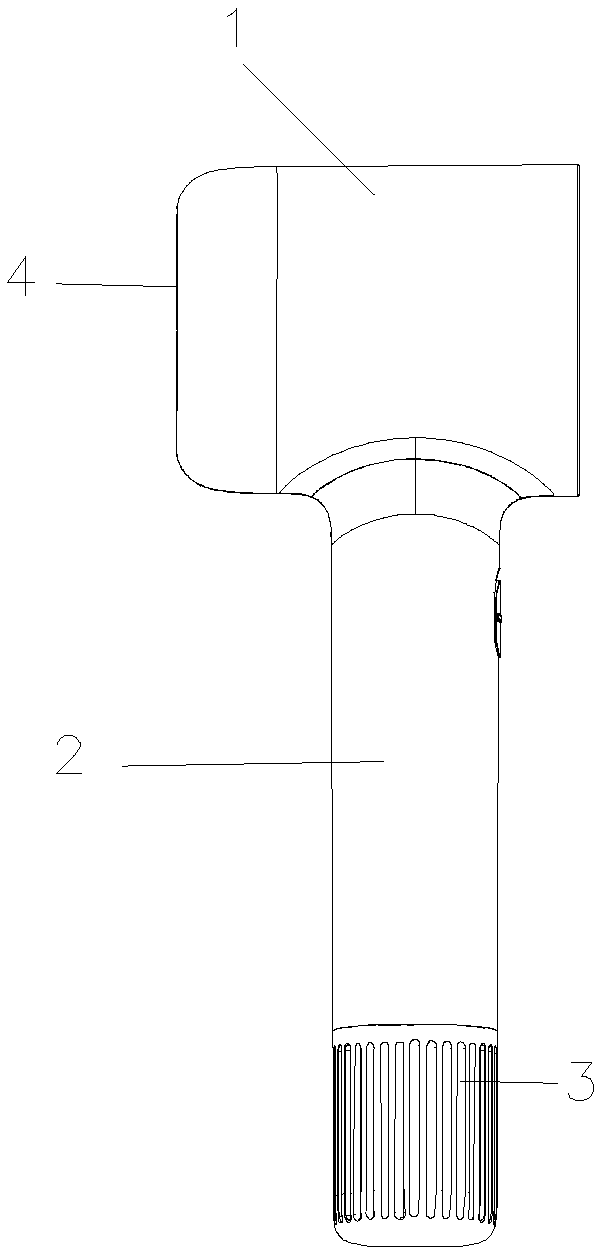

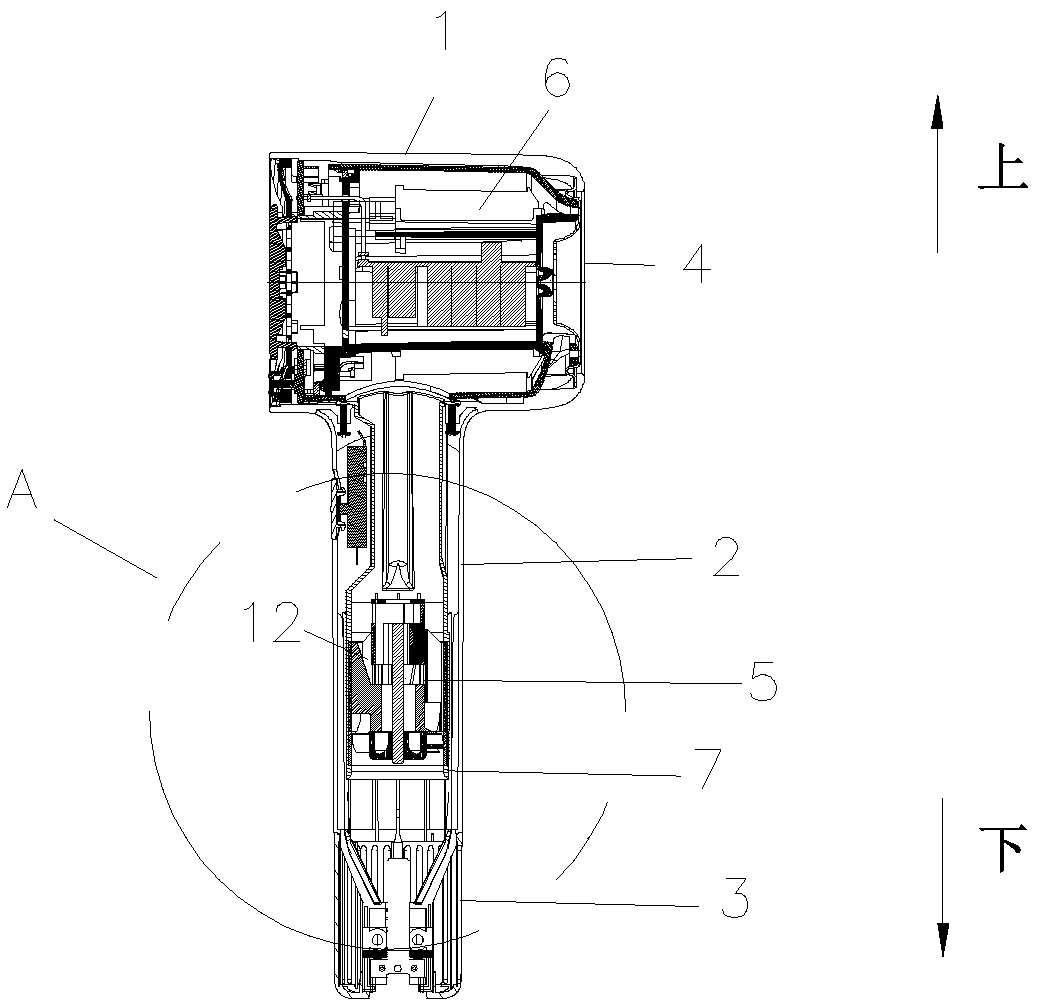

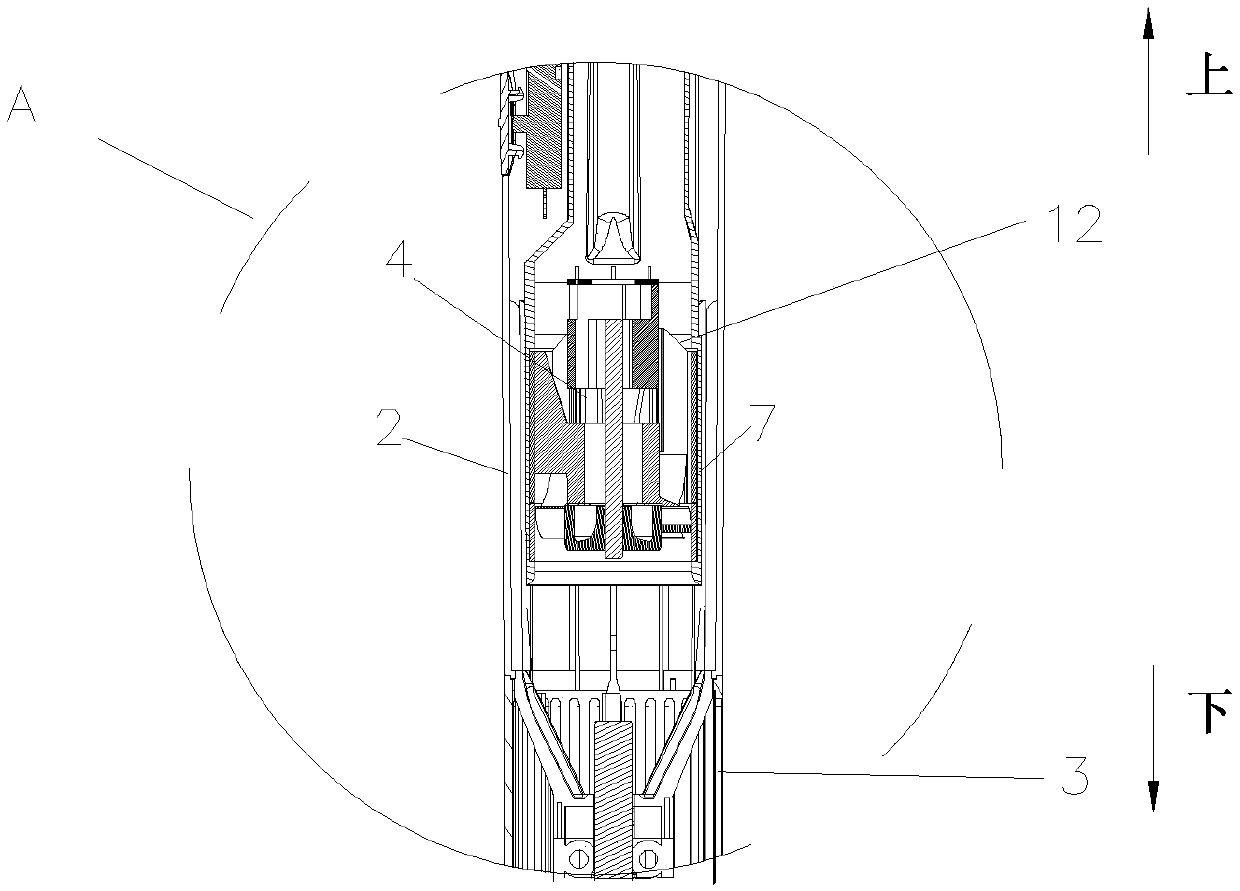

[0061] Such as Figures 1 to 11 As shown, a high-speed hair dryer includes a housing 1, a handle assembly 2 connected to the housing 1, an air inlet 3, an air outlet 4, a fan unit 5 for sucking air from the air inlet 3 into the inside of the hair dryer, and a fan unit 5 for The heating unit 6 for heating the airflow, the fan unit 5 includes a fan blade 502 and a motor 501 for driving the fan blade 502 to rotate, the motor 501 includes a stator assembly 15 and a rotor assembly 16, wherein the motor 501 also includes A bracket for supporting the rotor assembly 16 and the stator assembly 15; the rotor assembly 16 is connected to the fan blade 502 and drives the fan blade 502 to rotate; the bracket includes a first cylinder 8 for supporting the rotor assembly 16 and a housing The second cylinder 9 of the fan blade 502; the first cylinder 8 is arranged on one side of the second cylinder 9 and is connected with the second cylinder 9 through the connecting blade 10; the hair dryer al...

Embodiment 2

[0082] The difference between this embodiment and Embodiment 1 is that, if Figure 12 , 13 As shown, the second cylindrical body 9 includes an air inlet side 13 and an air outlet side 14 , and the first cylindrical body 8 is disposed on the air inlet side 13 of the second cylindrical body 9 .

[0083] The motor 501 can be arranged in the handle assembly 2. At this time, the air inlet 3 is arranged on the handle assembly 2, and the motor 501 is arranged above the air inlet 3. The axis of the motor 501 is the same as that of the handle assembly 2, and the air inlet side 13 is closer to The air inlet 3, when the fan blade 502 rotates, the air flow enters the second cylinder 9 from the air inlet 3, the air inlet 3 is located below the air inlet side 13 of the second cylinder 9, and the first cylinder 8 is located in the second cylinder The motor 501 can also be arranged in the housing 1, the air inlet 3 is arranged at the rear end of the housing 1, the axis of the motor 501 is th...

Embodiment 3

[0088] The difference between this embodiment and any of the above embodiments is that, if Figures 14 to 16 As shown, the hair dryer also includes a third cylinder 11 for fixing the motor 501, the third cylinder 11 and the first cylinder 8 define an air flow channel 12, and the third cylinder 11 is separated from the bracket set up. When the fan blade 502 rotates, the airflow entering the hair dryer from the air inlet 3 first enters the airflow channel 12 and then enters the second cylinder 9; or the airflow entering the hair dryer from the air inlet 3 enters the second cylinder 9 first, Then enter the airflow channel 12.

[0089] Further, the second cylinder 9 includes an air inlet side 13 and an air outlet side 14, and the fan blade 502 rotates so that the airflow enters the second cylinder 9 from the air inlet side 13 and enters the airflow channel through the air outlet side 14 12.

[0090] The third cylinder 11 includes an abutting portion, and the abutting portion ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com