Patents

Literature

36results about How to "Guaranteed wind pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

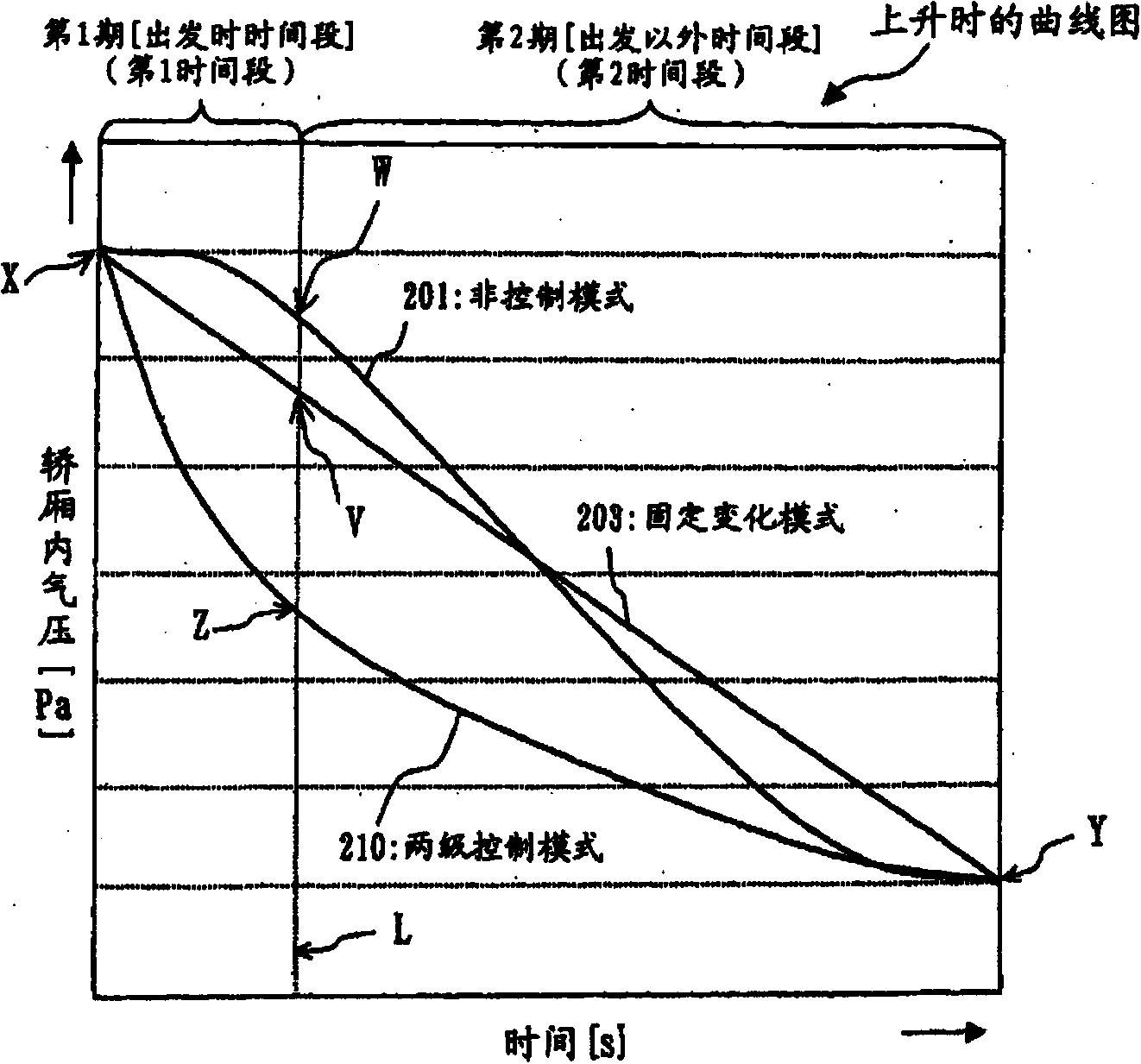

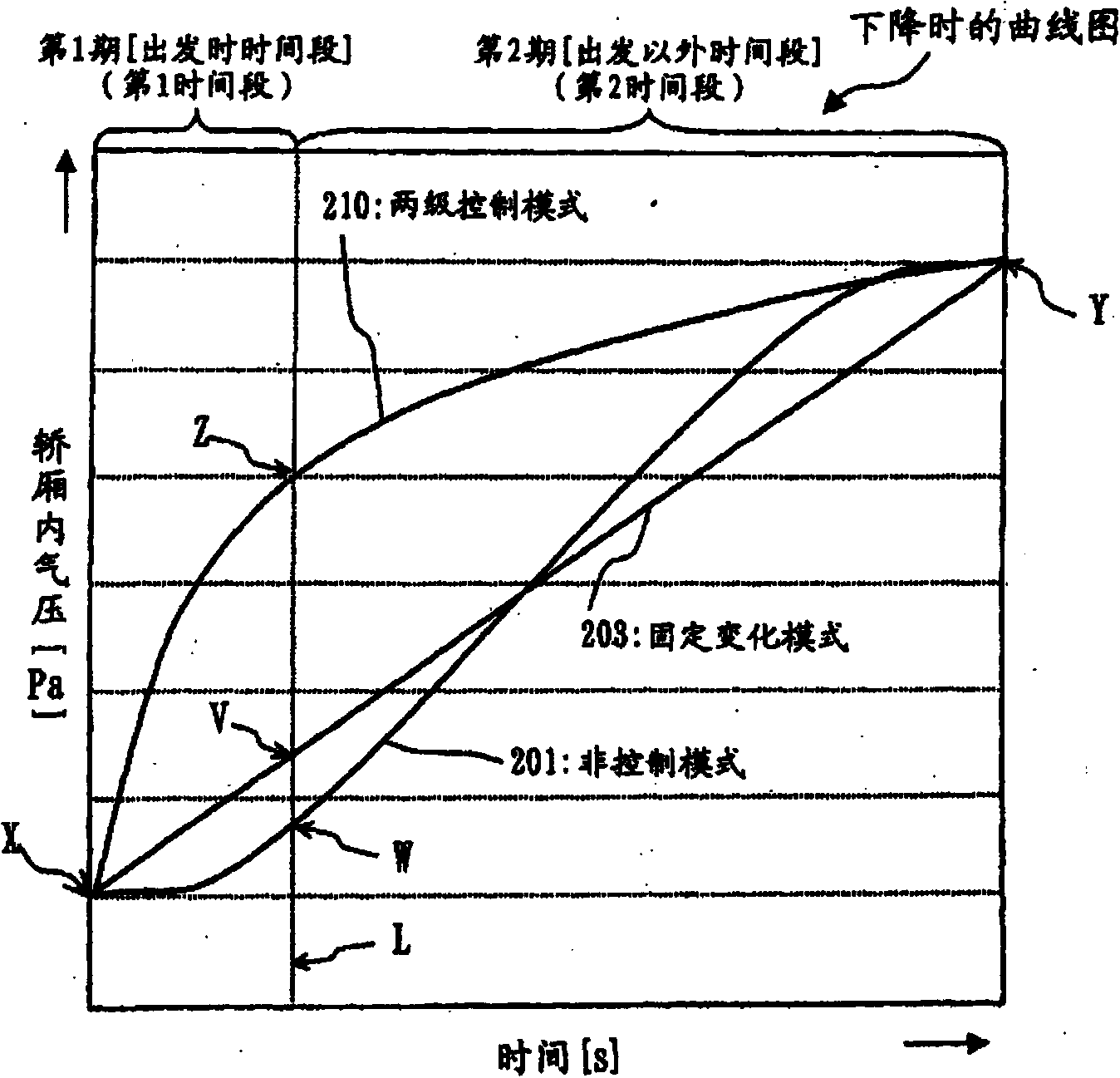

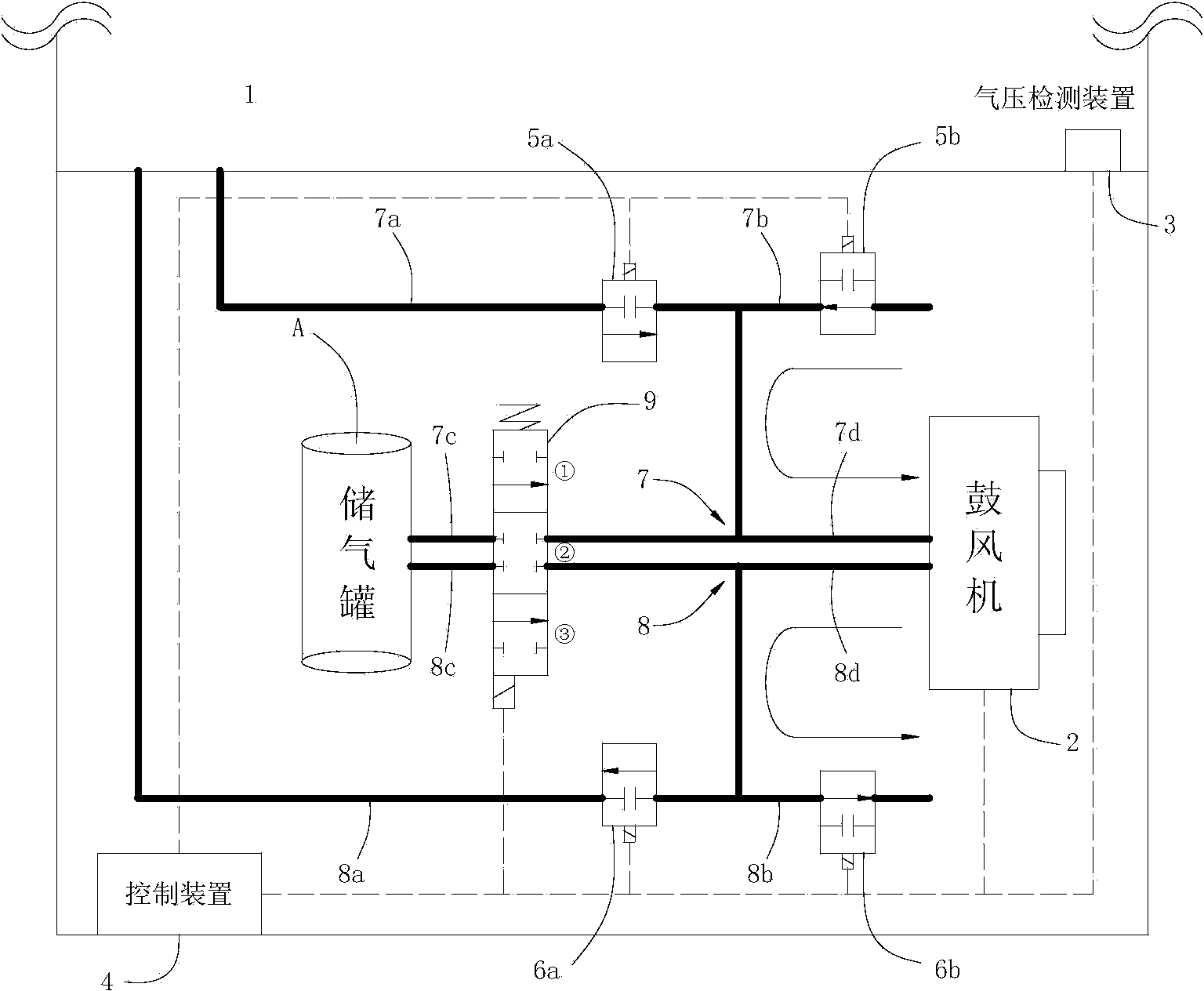

Pneumatic control system in elevator lift car

InactiveCN103879847AExtended service lifeIncrease wind pressureElevatorsBuilding liftsPositive airway pressureUltra high speed

The invention relates to a pneumatic control system in an elevator lift car. An elevator is controlled to reduce pressure in the elevator lift car in the ascending process or to increase pressure in the elevator lift car in the descending process. The pneumatic control system comprises an air blower, an air storage tank, a pressure reduction piping group, a pressure increase piping group, a valve set, an air pressure detecting device and a control device. The air blower is arranged at the bottom of the elevator lift car, air pressure is generated continuously in the same direction when the elevator operates, and air is filled into the air storage tank or exhausted from the air storage tank so that positive pressure or negative pressure can be formed. The pressure reduction piping group and the pressure increase piping group are connected with the elevator lift car, the air blower and the air storage tank. The valve set is arranged in the pressure reduction piping group and the pressure increase piping group for controlling air circulation. The air pressure detecting device detects the air pressure in the elevator lift car and outputs detection signals. The control device regulates the opening and closing and the opening size or the opening position of the valve set according to the detection signals and controls the air pressure in the elevator lift car. Compared with the prior art, the pneumatic control system in the elevator lift car can eliminate the discomfort of passengers due to ear pressure in the ultra high-speed elevator lift car in the lifting process.

Owner:TONGJI UNIV

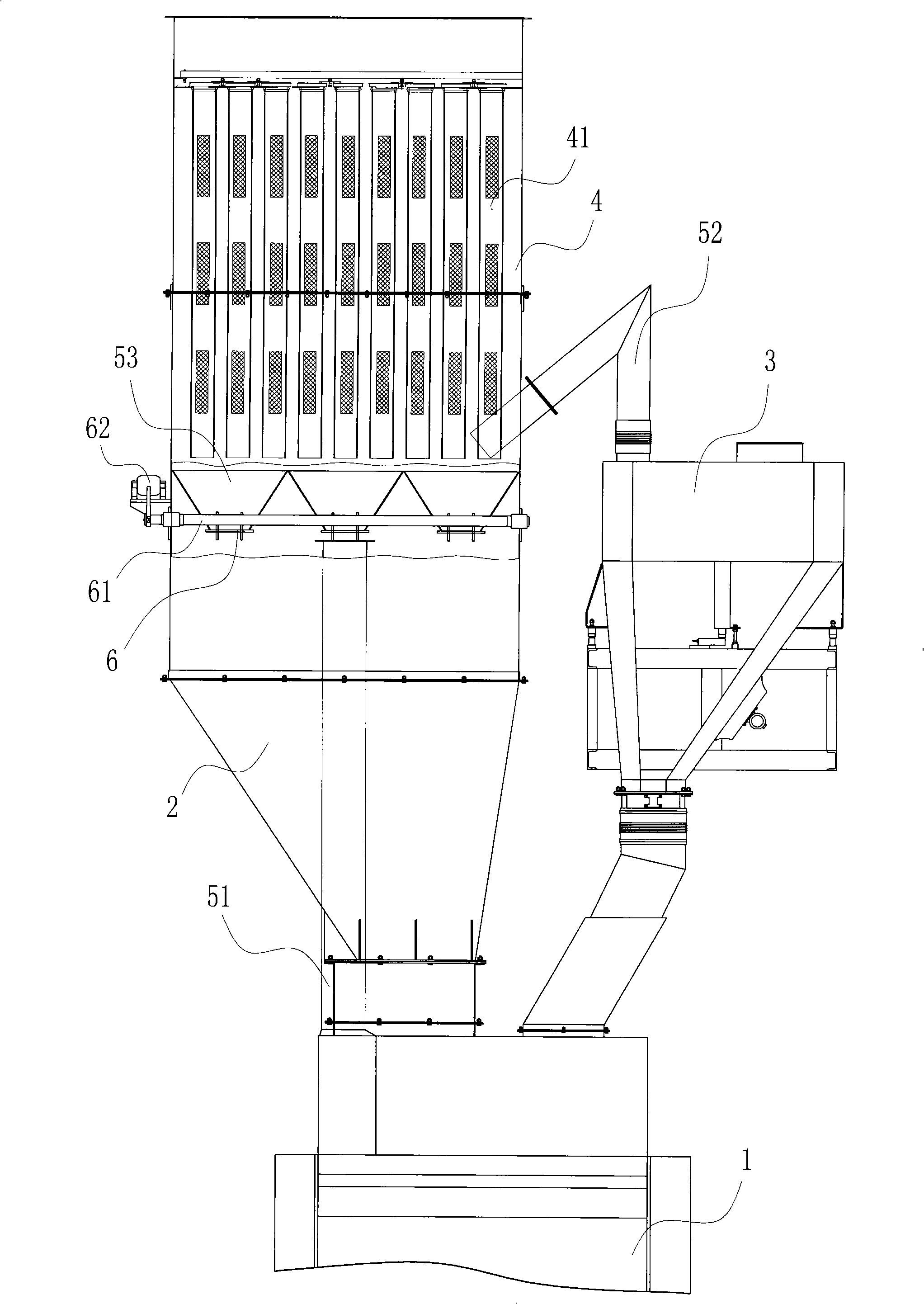

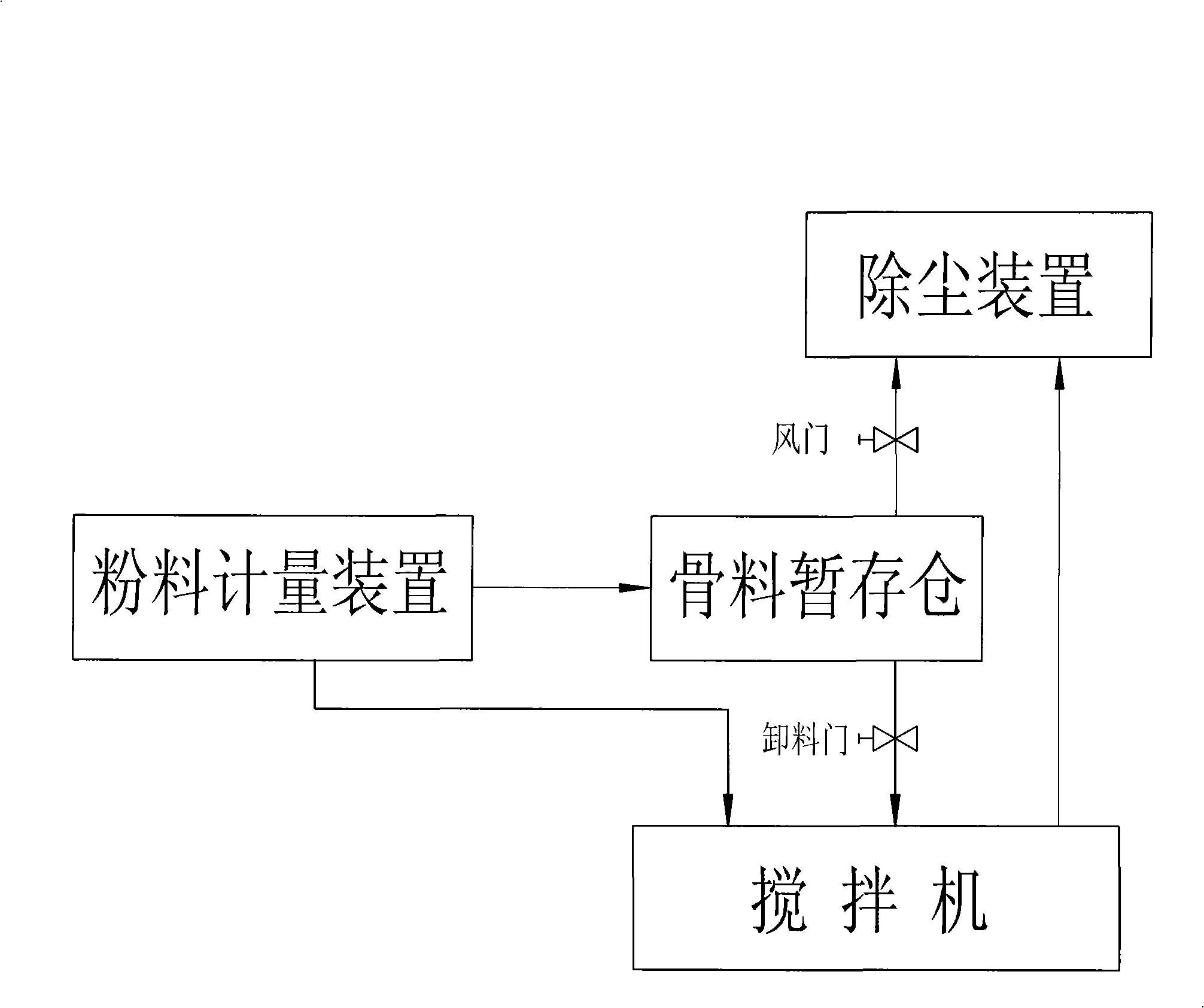

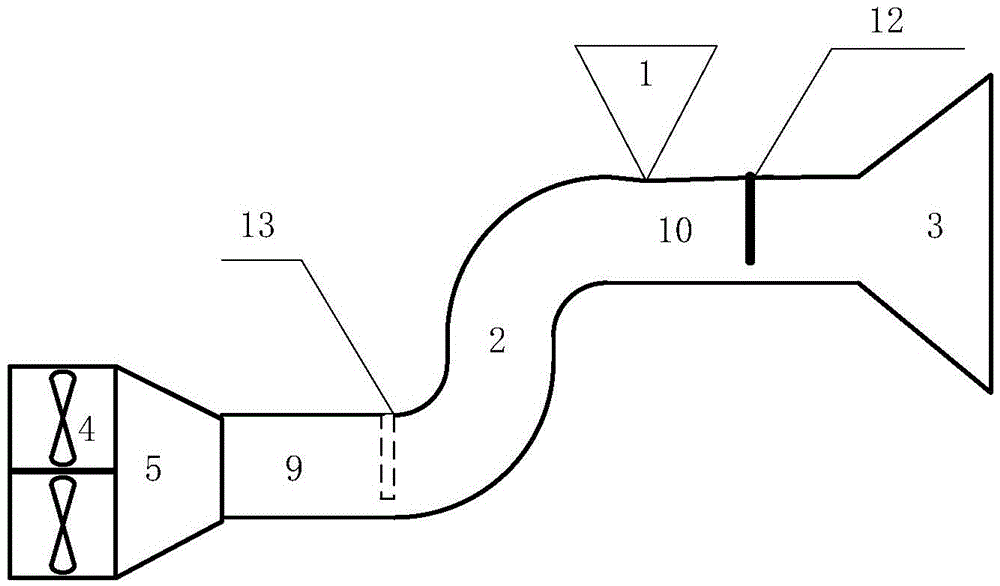

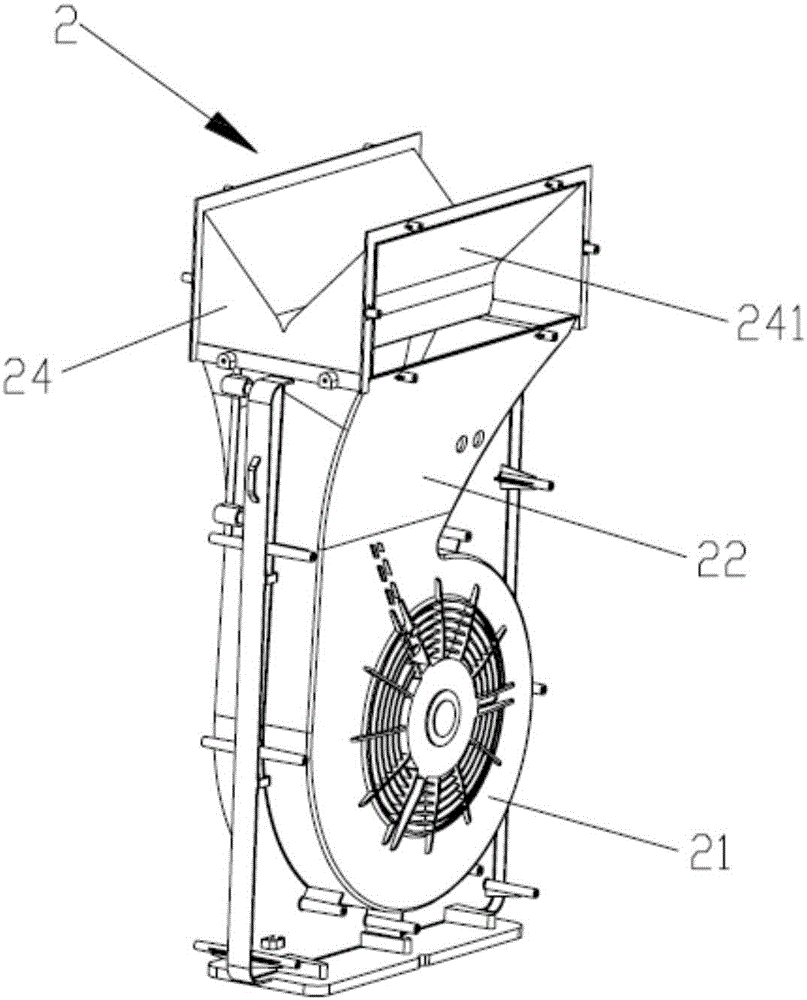

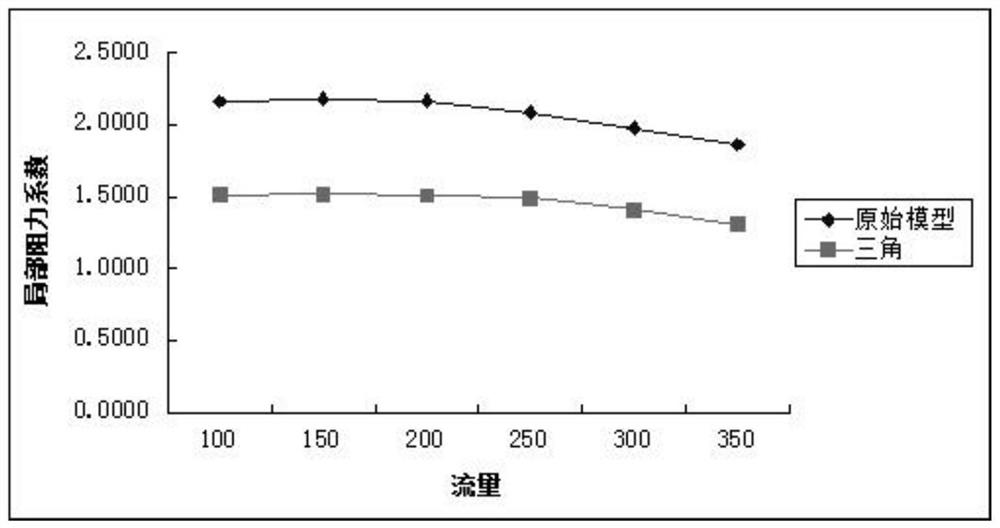

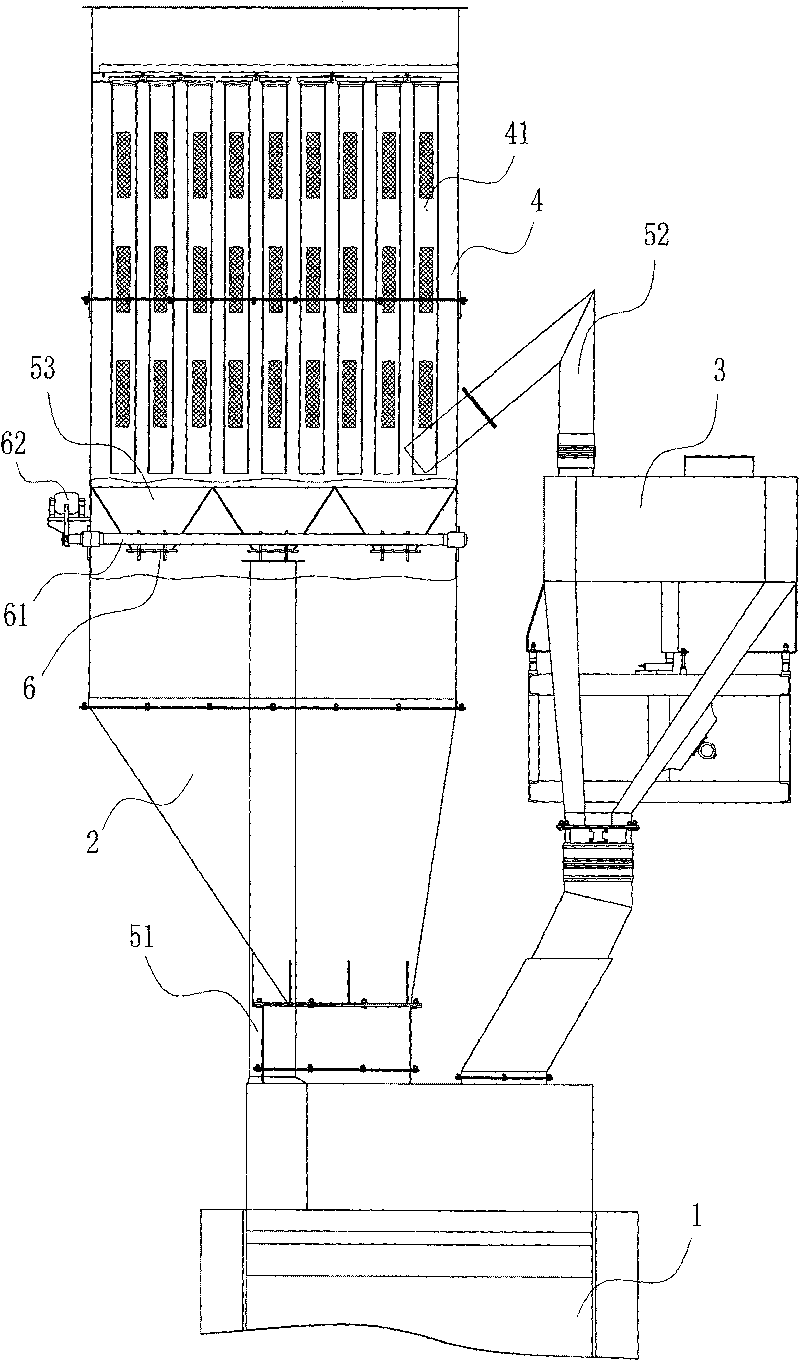

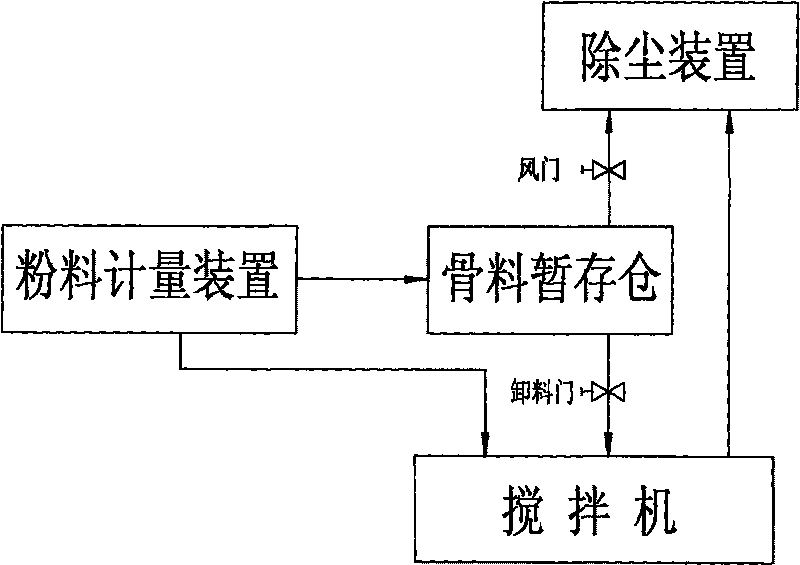

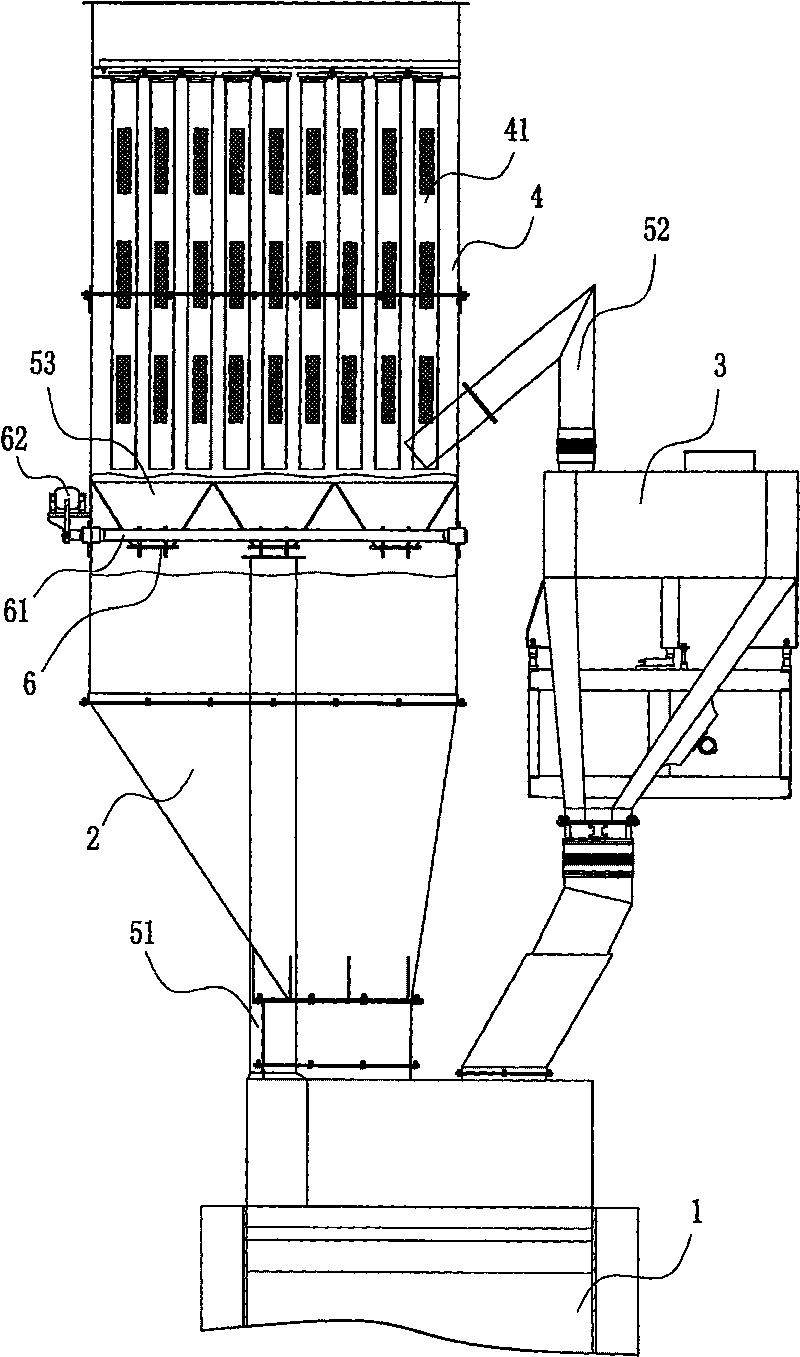

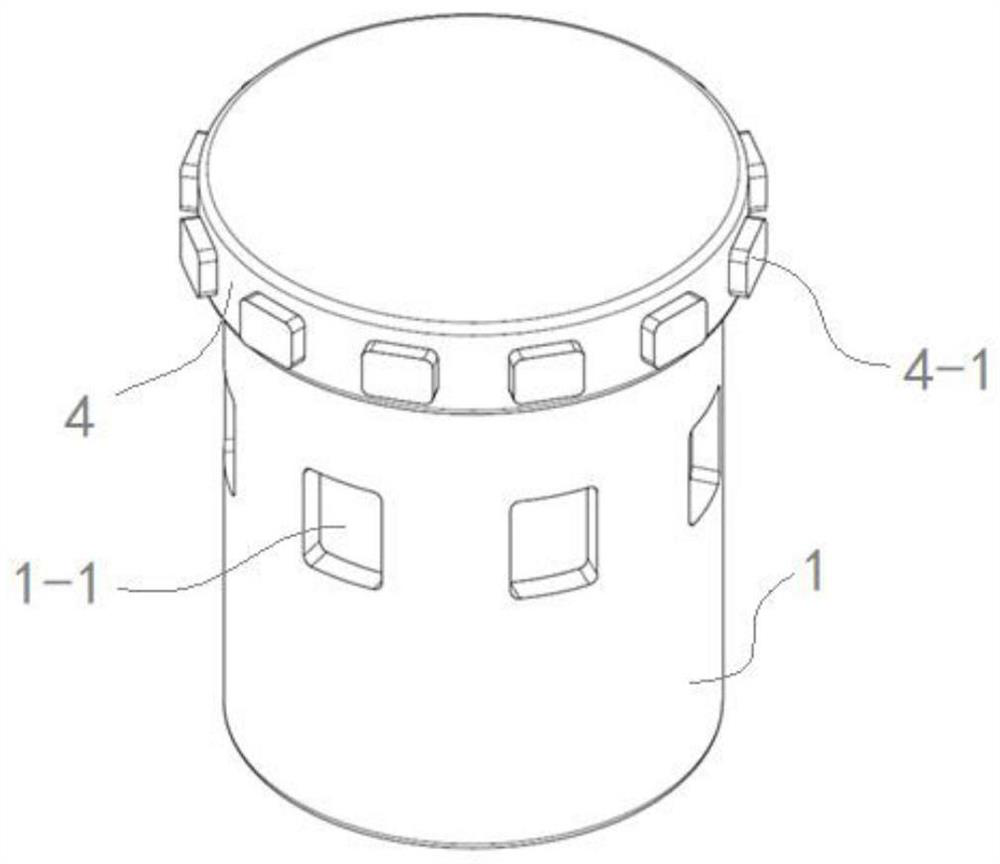

Concrete station and method for dedusting by stages according to operation process

ActiveCN101352895ACompact structureReduced size and footprintMixing operation plantConstruction aggregateControl unit

The invention relates to a concrete mixing plant which can carry out staged dedusting in the working process and a method; the concrete mixing plant consists of a stirring mill, an aggregate temporary storage bin, a main tower composed of a powder metering device, a dust removing device and a control unit. The stirring mill is communicated with the dust removing device by a first dust transfer passage, the powder metering device is communicated with the aggregate temporary storage bin by a second dust transfer passage, the dust removing device is connected with the aggregate temporary storage bin and is communicated with the aggregate temporary storage bin by a third dust transfer passage, the third dust transfer passage is internally equipped with a ventilation door which can be opened or closed, the ventilation door can be manipulated by a door operation mechanism to shift between an open position and a closed position, and the door operation mechanism is arranged to be controlled by the control unit. The staged dedusting method is characterized in that: the dust removing device can carry out dedusting operation during the process of putting aggregate into the aggregate temporary storage bin by optionally closing or opening the ventilation door, while dedusting operation is stopped during the process of transferring the aggregate from the aggregate temporary storage bin into the stirring mill.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

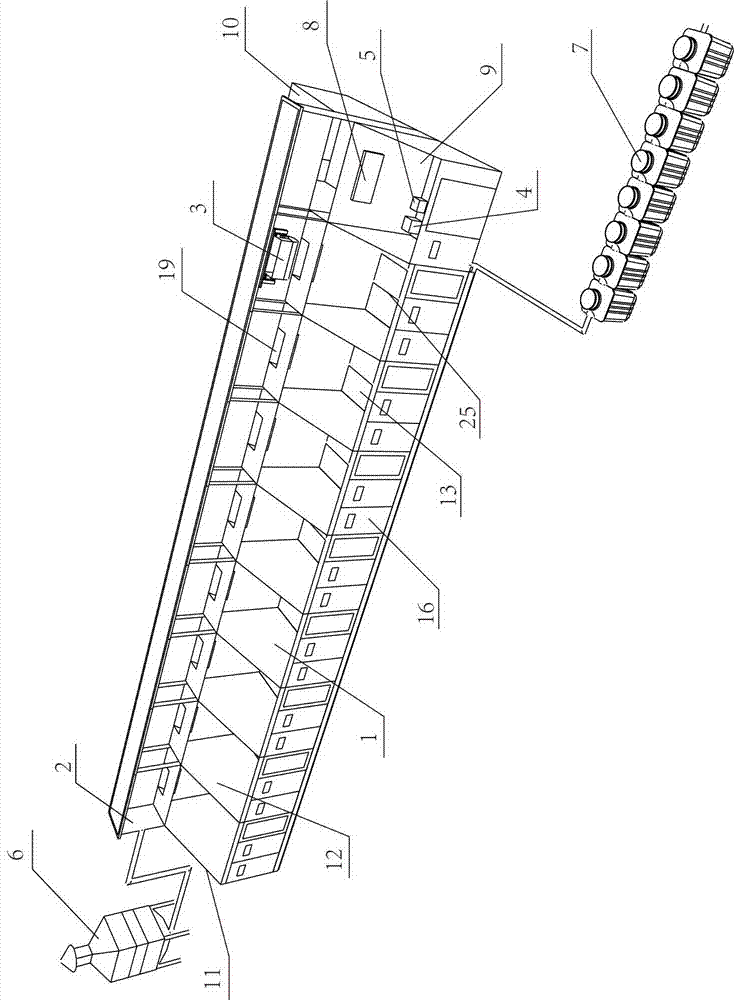

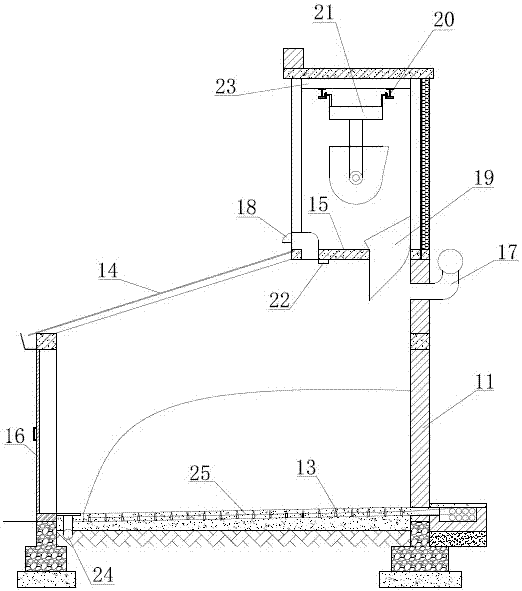

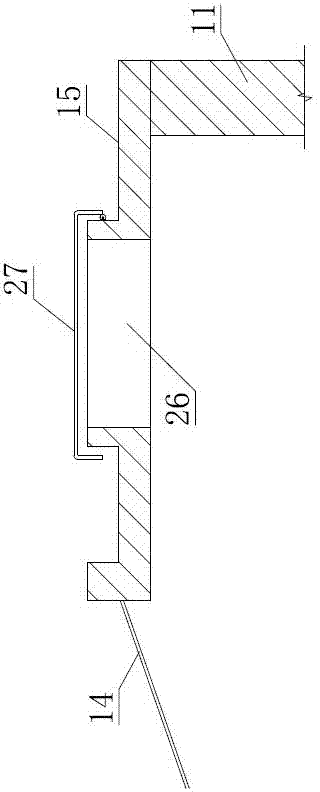

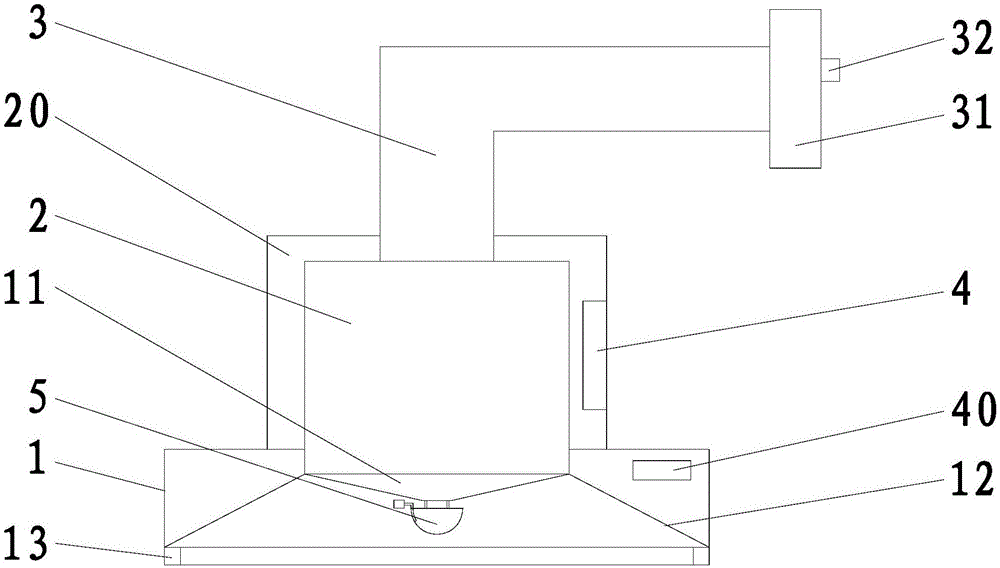

Intelligent sunlight garbage composting house

InactiveCN107382385ASolve operational problemsSolve labor intensityClimate change adaptationEnergy inputLitterOrganic matter

The invention relates to the field of life organic matter compost, and concretely relates to an intelligent compost sunlight house. The sunlight house comprises multiple bottom composting rooms which are arranged side by side, an upper mechanical feeding layer, a separate supply type constant pressure ventilation and oxygen supply system, and a separate supply type liquid sprinkling system, wherein the upper mechanical feeding layer is arranged at the upper part of the composting rooms, and the separate supply type constant pressure ventilation and oxygen supply system and the separate supply type liquid sprinkling system are arranged in the composting rooms. The composting rooms are in the five technical processes of idle state (waiting for feeding), feeding, oxygen supply and fermentation, standing, and discharging at the same time, percolate is treated and exhaust gas is purified, so that the whole composting process does not cause environmental pollution. The composting rooms have the characteristics of reasonable structures, improved function, high intelligence, good composting effects, operation and maintenance convenience, effective utilization of solar energy, and the like.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

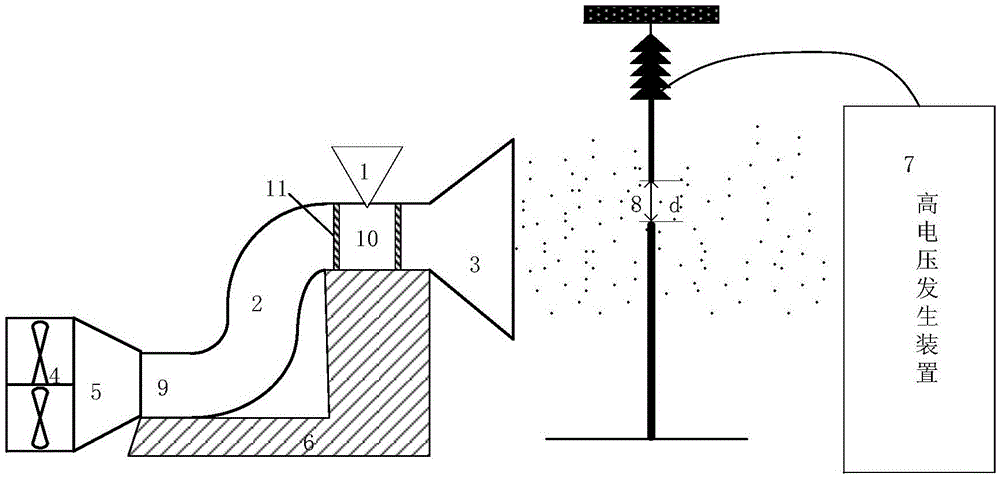

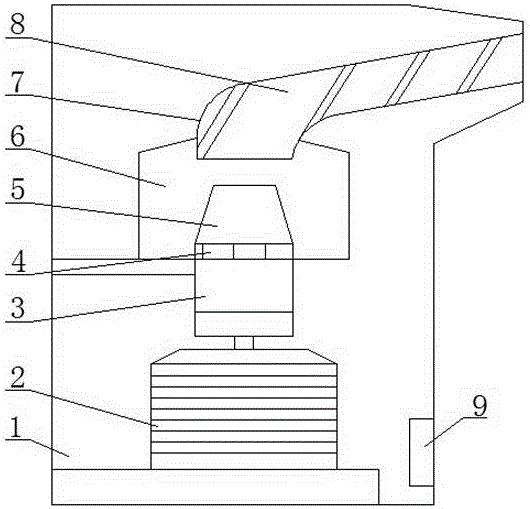

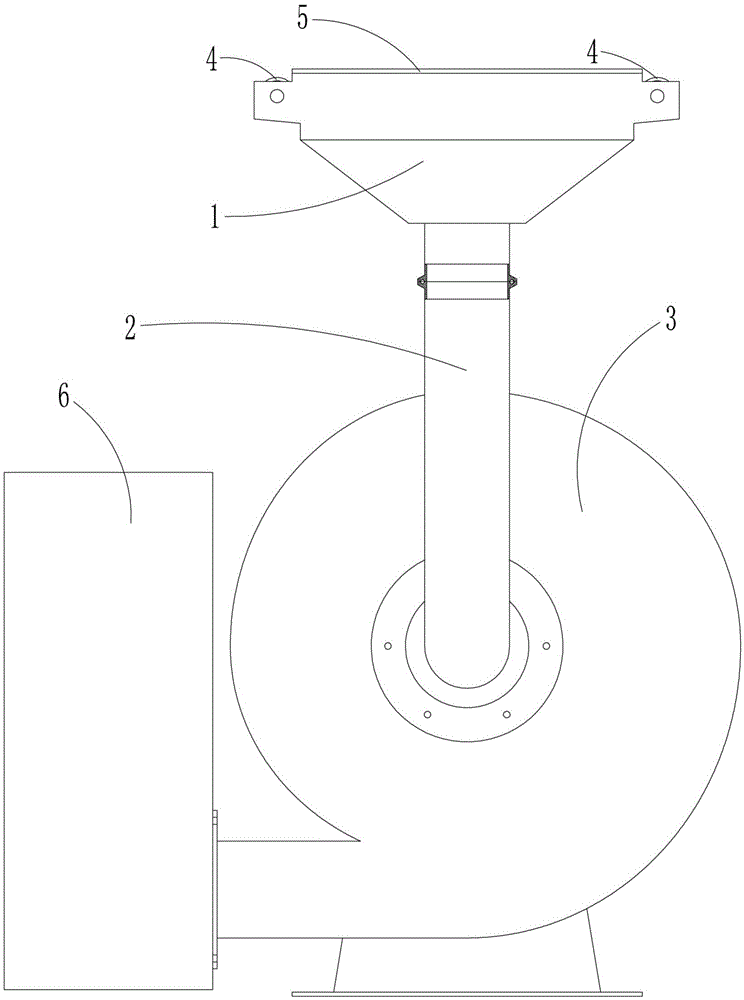

Gap discharge characteristic detection system under sand-dust condition

InactiveCN105606965ADiffusion is sufficient and uniformEasy to controlTesting dielectric strengthEngineeringTest requirements

The invention provides a gap discharge characteristic detection system under a sand-dust condition, the system comprises a sand-dust environment simulation device and a high voltage generator, the sand-dust environment simulation device is used for simulating a sand-dust environment, a gap is arranged in the sand-dust environment, and the high voltage generator is connected with the two ends of the gap in parallel and is used for providing high voltage to the gap. The technical scheme provided by the invention can stably simulate the sand-dust environment and can be used in various air gap discharge characteristic test, such as rod-rod gap, rod-plate gap, plate-plate gap and the like, gap discharge characteristic tests under conditions of different voltage types, different wind speed, sand existing, sand unexisting, different sand-dust concentration can be selected according to the test requirement, so that the reference and guidance are provided for a construction of an extra-high voltage DC transmission line.

Owner:CHINA ELECTRIC POWER RES INST +2

Kitchen ventilator convenient to use

InactiveCN106765392ASufficient output powerEfficient dischargeDomestic stoves or rangesLighting and heating apparatusEngineeringCheck valve

The invention discloses a kitchen ventilator convenient to use. The kitchen ventilator comprises a smoke absorbing cover, a protective cover, a draught fan, a smoke exhaust pipe, a pressure detecting head and a control device. The upper portion of the smoke absorbing cover is connected with the draught fan provided with a plurality of gears; the protective cover covers the draught fan; the draught fan is connected with the smoke exhaust pipe; a smoke outlet of the smoke exhaust pipe is connected with a flue check valve; the pressure detecting head is fixed on the flue side of the flue check valve; the pressure detecting head and the draught fan are both connected with the control device through connecting lines; and the smoke absorbing cover is composed of a smoke inlet part located in the middle part of the kitchen ventilator and a smoke collecting part around the smoke inlet part. The pressure detecting head is fixed on the flue side of the flue check valve, so that the control device can timely adjust the gears of the draught fan according to the pressure in the flue, and the draught fan has enough output power to guarantee air pressure and guarantees that lampblack can be discharged timely and effectively.

Owner:JIAXING JIALEFU NEW ENERGY

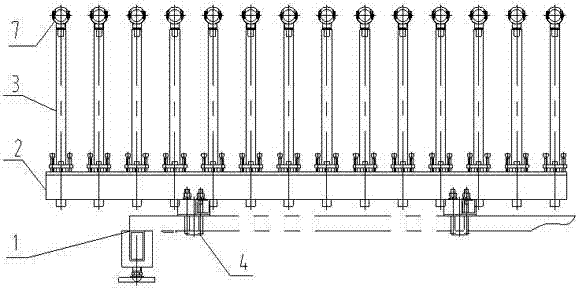

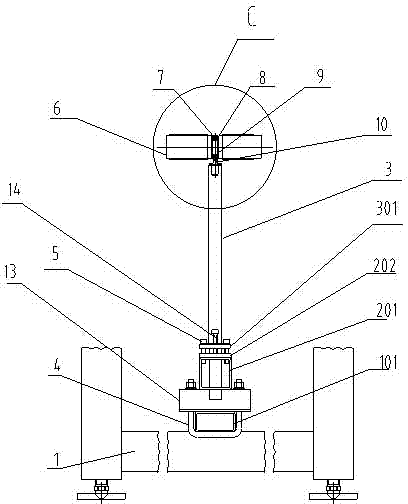

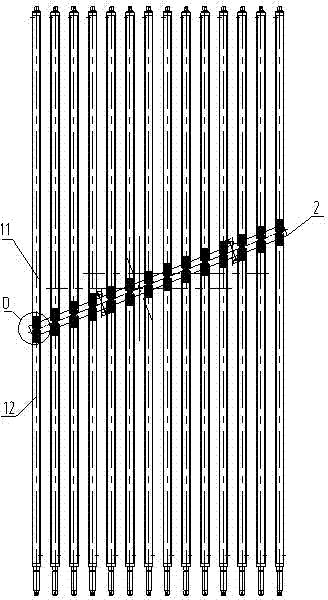

Rollgang for flat quenches for glass tempering

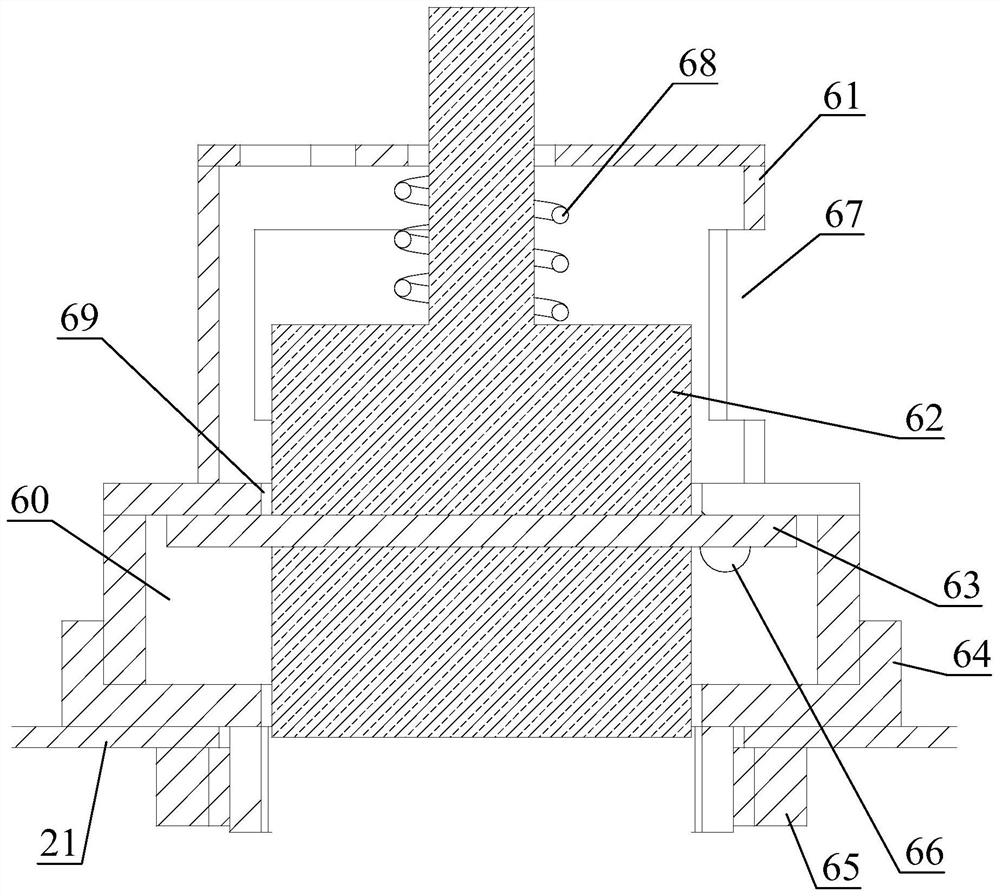

InactiveCN104724920AEliminates down deflectionImprove qualityGlass transportation apparatusGlass tempering apparatusToughened glassPlain bearing

The invention discloses a rollgang for flat quenches for glass tempering, which comprises a rack and multiple conveying rolls, wherein the multiple conveying rolls are parallelly arranged on the rack at certain interval, at least one conveying roll is composed of two sections of rollers, a middle rollgang supporting device is also provided, the middle rollgang supporting device comprises a mounting seat, a mounting frame, a support rod and a sliding bearing pedestal, the mounting frame is connected with the mounting seat, one end of the support rod is fixedly connected with the mounting frame, the other end of the support rod is fixedly connected with the sliding bearing pedestal, a sliding bearing is arranged in the sliding bearing pedestal, the two ends of the sliding bearing are respectively provided with a plane bearing, a connecting head is respectively arranged in inner holes of the sliding bearing and the plane bearings, the two ends of the connecting heads are respectively connected with the two sections of rollers constituting a same conveying roll, and the top end of the sliding bearing pedestal is not higher than the rotary supporting surface of the conveying roll. By using the rollgang disclosed by the invention, the down-warping of the middle part of the rollgang can be eliminated, thereby improving the quality of tempered glass.

Owner:LUOYANG NORTHGLASS TECH +1

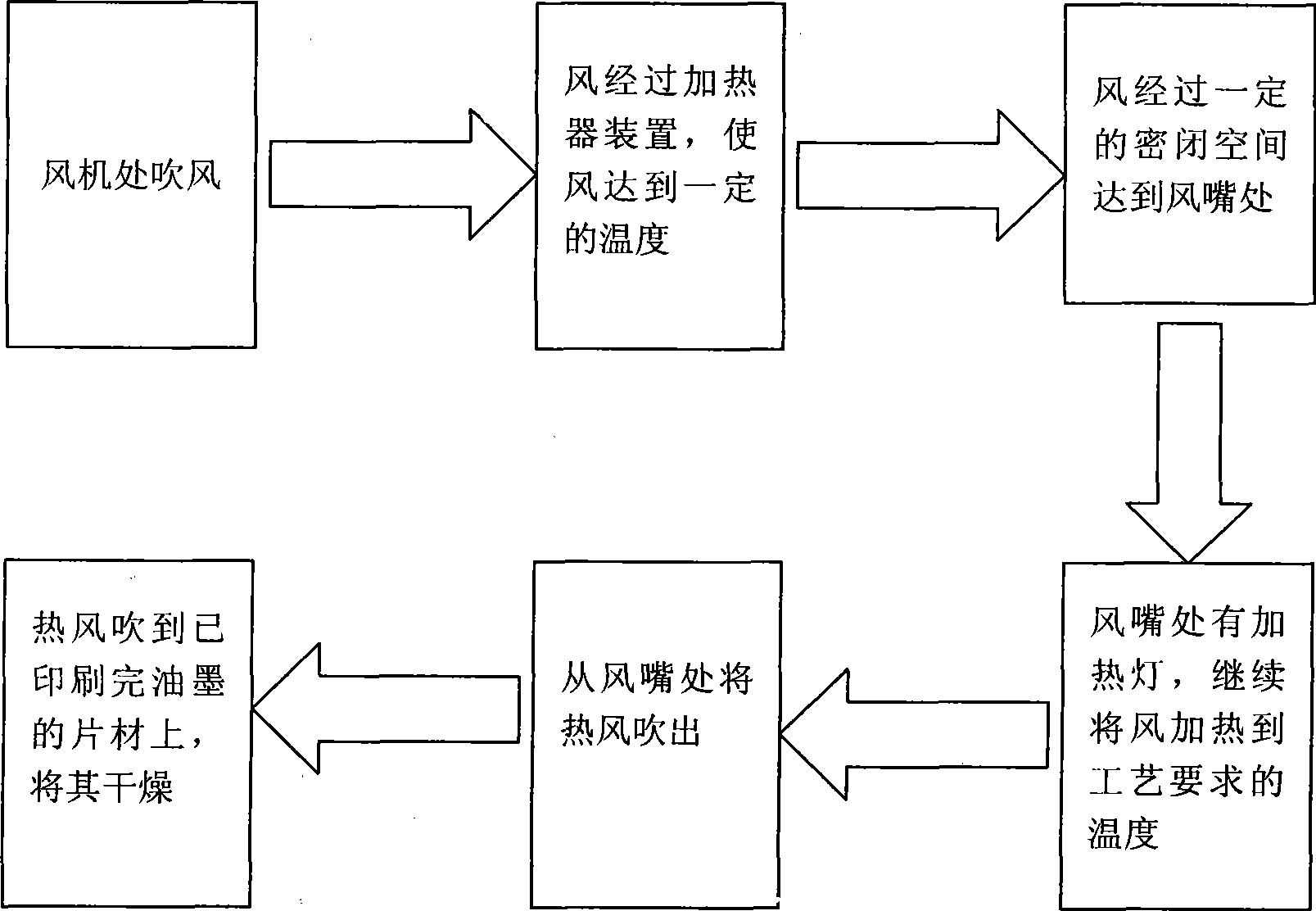

Apparatus for drying mirror silver ink and technique thereof

InactiveCN101462398AGuaranteed uniformityGuaranteed stabilityPretreated surfacesCoatingsSilver inkAir volume

The invention discloses drying equipment for mirror silver ink and a process thereof. The process is characterized in that special drying equipment provides a hot air drying area that an initial end section is a low temperature area, an intermediate section is a high temperature area, and a tail end section is a low temperature area, and the three sections are continuously connected; and a drying method for heating and sectional control of sheets with ink printed on the surfaces by low temperature-high temperature-low temperature sectionalization is adopted to dry the ink on the surfaces of the sheets. The adoption of a mode of sectional heating and sectional control of low temperature at both ends and high temperature at the intermediate position has the advantages that a drying mode that the prior process adopts a human observation mode for inspection, no corresponding formed process parameters exist and the human observation mode is adopted for inspection is improved; a heater device is arranged at an air inlet of a blower to make the temperature of blown air reach certain process requirement; and a cylindrical blast nozzle is used at an air outlet to maintain certain wind pressure to ensure the uniformity and stability of air volume, thereby ensuring that a solvent in the ink is quickly volatilized to obtain the mirror effect with higher brightness.

Owner:TIANJIN ZHONGHUAN HI TECH

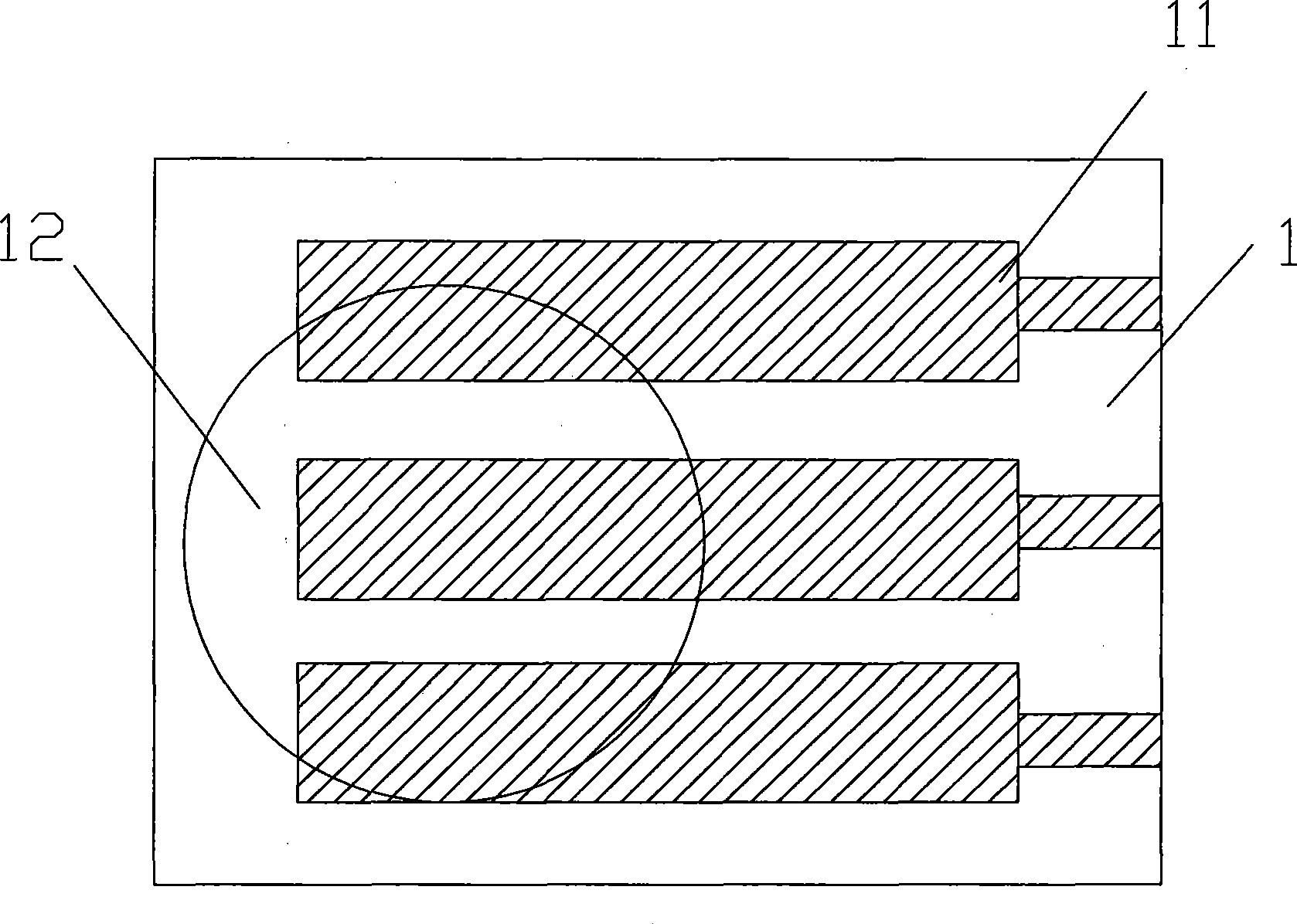

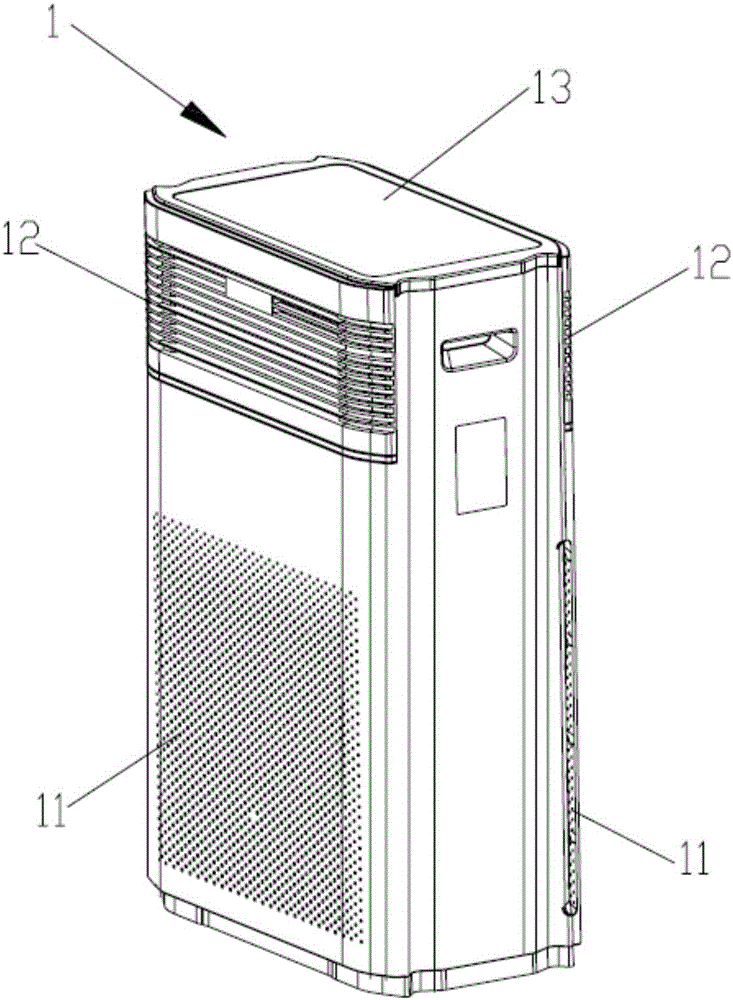

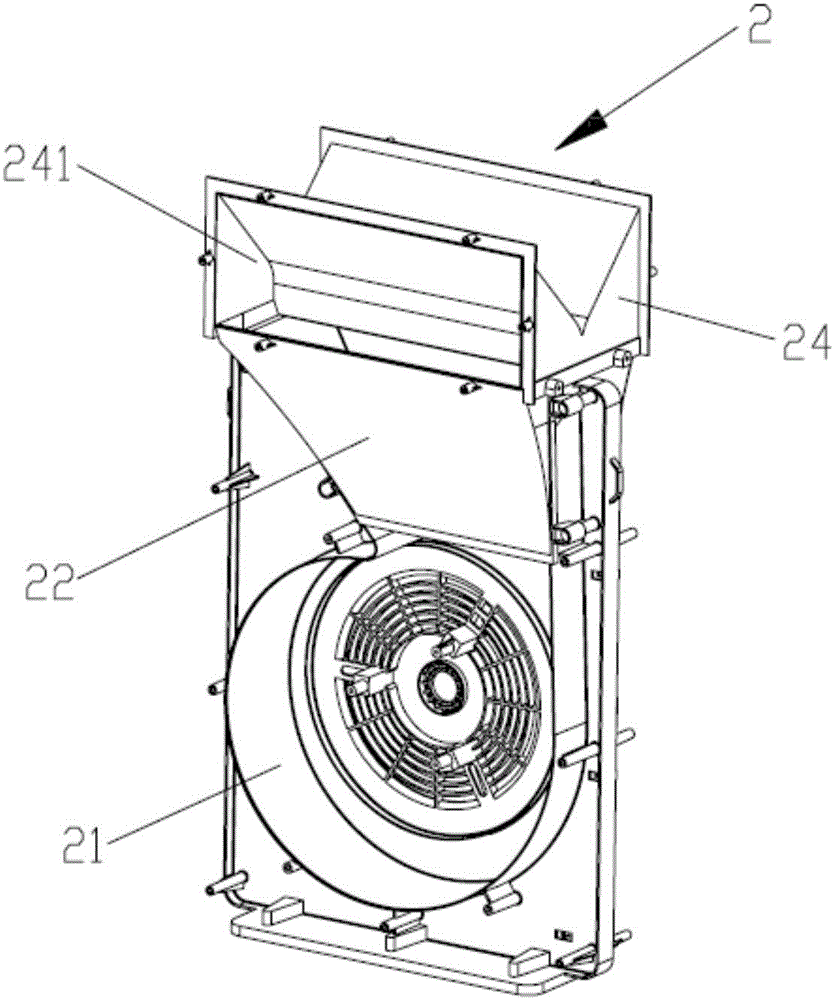

Air purifier with air outlets in double surfaces

InactiveCN106678996AReduce working noiseReduce consumptionDucting arrangementsMechanical apparatusAir purifiersTurbine

The invention relates to the technical field of air purifiers, in particular to an air purifier with air outlets in double surfaces. The air purifier comprises a shell and an air flue fixed in the shell, wherein two air inlets are respectively formed in two sides of the lower part of the shell; two air outlets are respectively formed in two sides of the upper part of the shell; the air flue comprises a turbine casing and an air supply cavity connected to the upper part of the turbine casing; a motor is mounted in the turbine casing; a rotating shaft of the motor is connected with a bidirectional wind wheel; two sides of the bidirectional wind wheel respectively communicate with the two air inlets; the upper part of the air supply cavity is connected with an air discharge component; two air discharge channels with the same structures are symmetrically arranged on the air discharge component; and the two air discharge channels respectively communicate with the two air outlets. By the two air inlets and the two air outlets, purified air quantity is greatly increased, and the purifying efficiency is improved; the structures of the two air discharge channels of the air discharge component are symmetric and the same, so that air discharge of the two air outlets is consistent, the air speed is even, air pressure loss is small, and noises of the purifier are reduced.

Owner:SHANGHAI SAIFEI ENVIRONMENTAL TECH

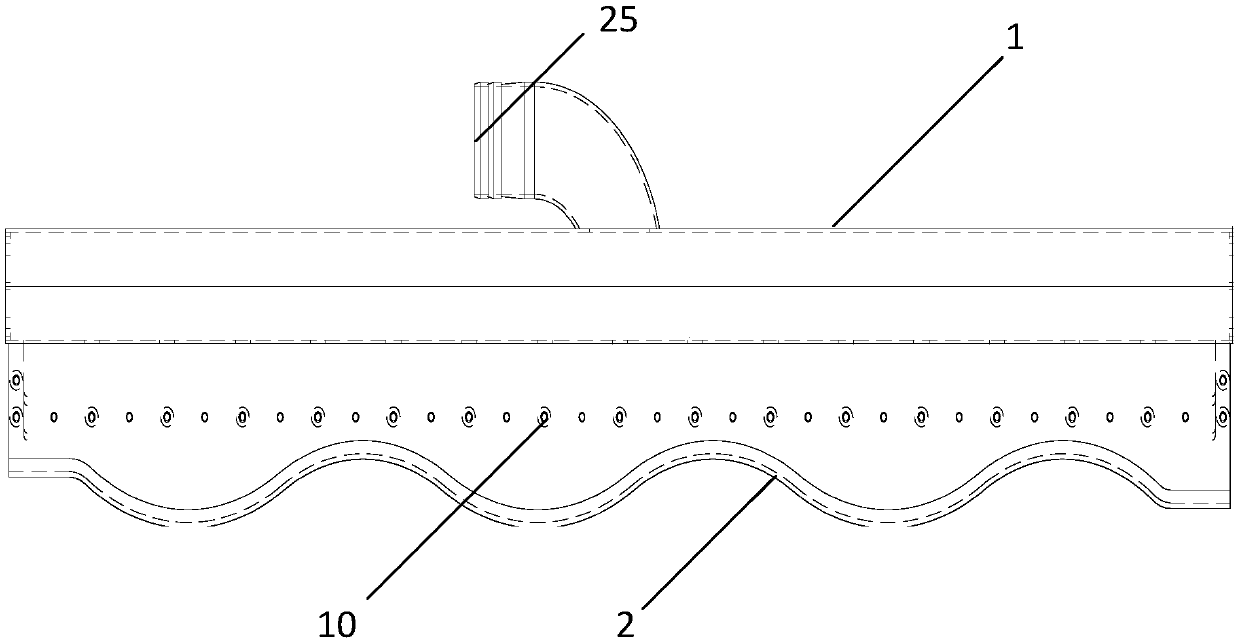

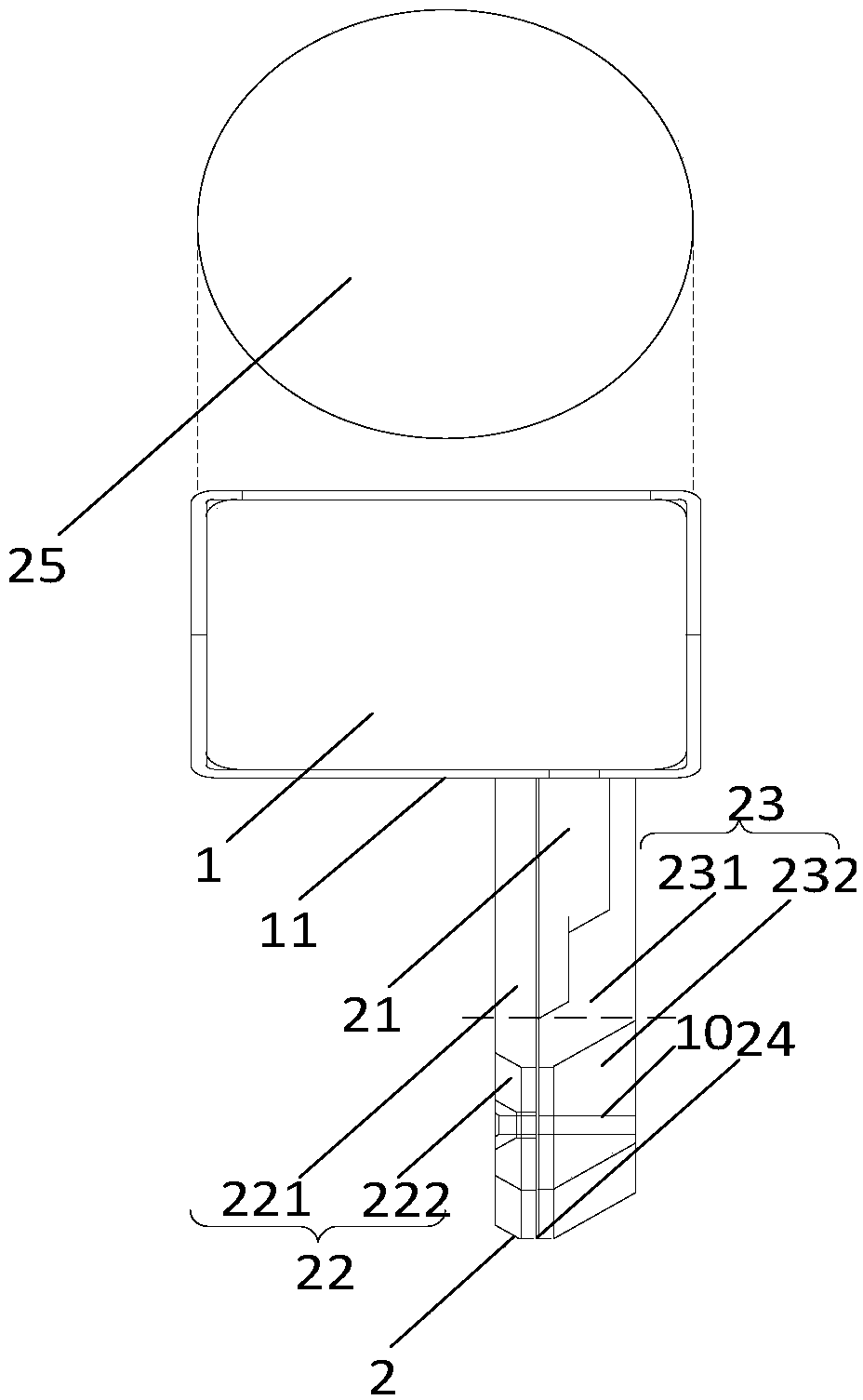

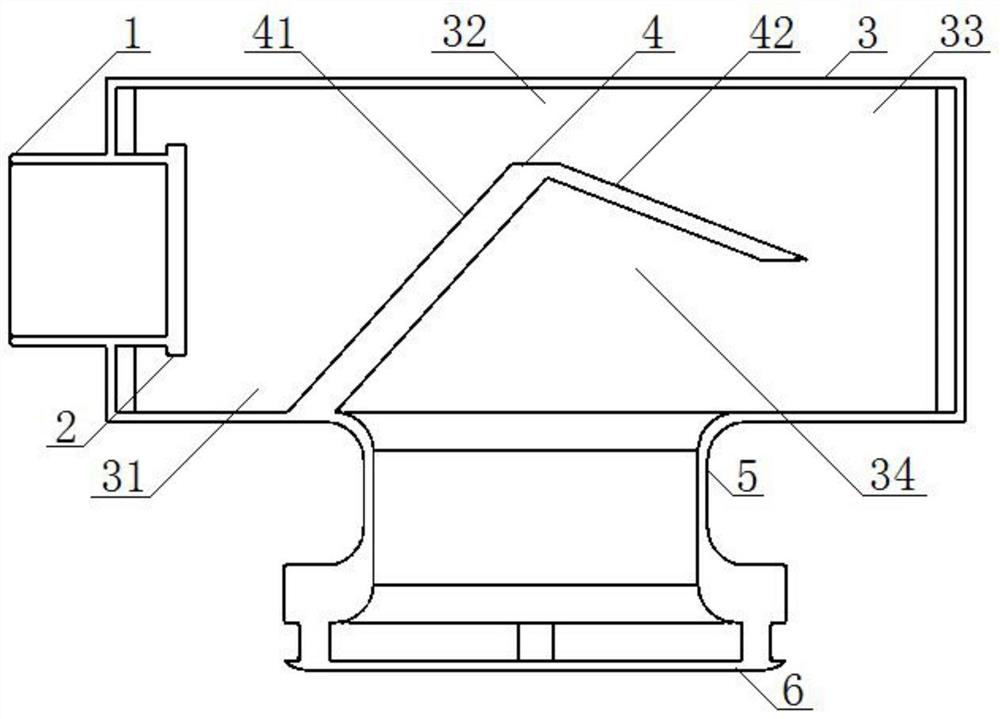

Drying device and cleaning system

PendingCN110953871AAchieve the purpose of dryingGuaranteed wind pressureDrying gas arrangementsEngineeringAir knife

The invention discloses a drying device and a cleaning system, which relate to the technical field of cleaning and drying, and aim to solve the problem of drying a cleaned curved glass plate. The drying device comprises a ventilation assembly and an air knife arranged on the ventilation assembly, wherein the air knife is communicated with a draught fan through the ventilation assembly, the air knife comprises an air knife cavity communicated with the ventilation assembly, and an air outlet communicated with the interior of the air knife cavity is formed in the air knife cavity; and the shape of the air outlet is matched with the surface shape of a dried object. The cleaning system comprises the drying device in the technical scheme. The drying device and the cleaning system are used for the technical field of cleaning and drying.

Owner:DONGJUN NEW ENERGY CO LTD

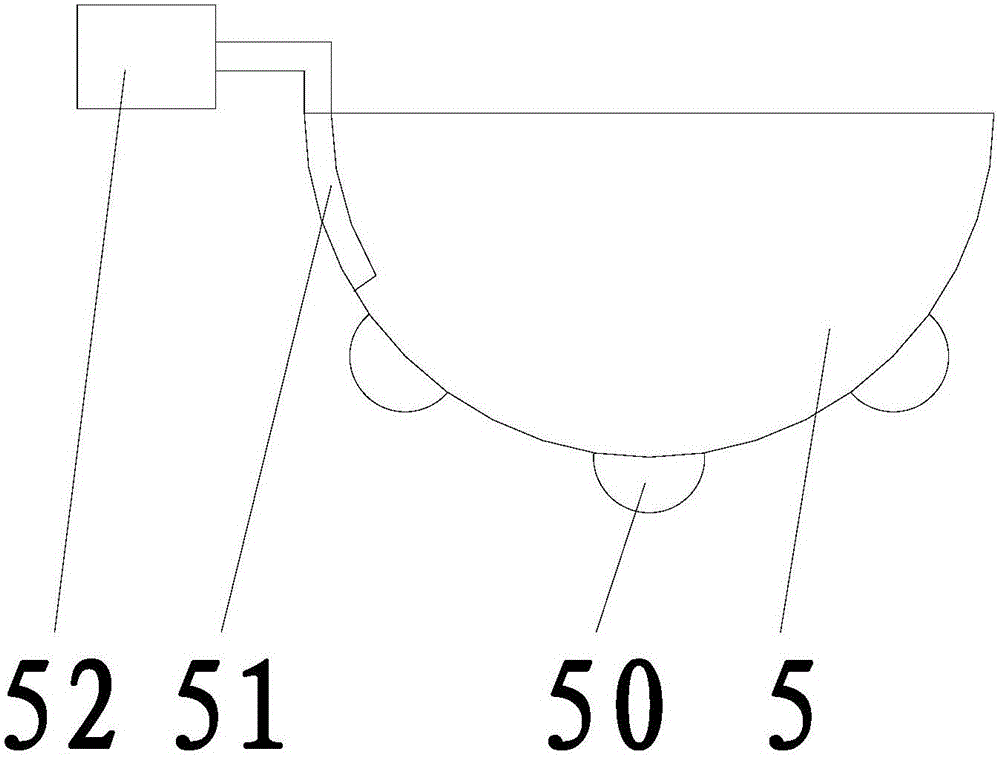

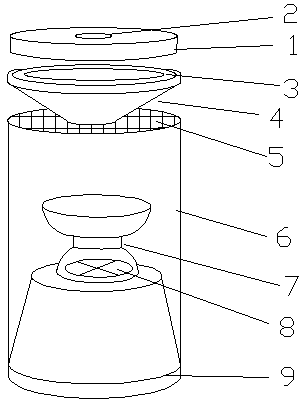

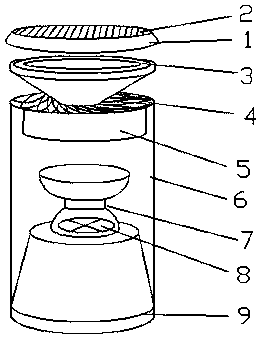

Radiation-free mosquito killing lamp

The invention discloses a radiation-free mosquito killing lamp. The radiation-free mosquito killing lamp includes a top cover, a switch, an ultraviolet lamp tube, a lampshade, a wind net, a mosquito cage, a wind channel, a turbine fan and a fan. The switch is located at the center of the upper part of the top cover. The ultraviolet lamp tube is located under the top cover. The mosquito cage is located under the lampshade. The mosquito cage connects the wind net and the base. The wind channel is of a funnel shape and located in the mosquito cage. The turbine fan is located in the lower half funnel of the wind channel. The base bears the whole structure. The radiation-free mosquito killing lamp of the invention utilizes a unique light wave of ultraviolet to attract mosquitoes, and catches the mosquitoes through the cooperation of the wind net, wind channel and turbine fan and by utilizing wind pressure and wind quantity so as to achieve the effect of radiation-free mosquito killing.

Owner:JIANGSU HUAXIA INTPROP SERVICE CO LTD

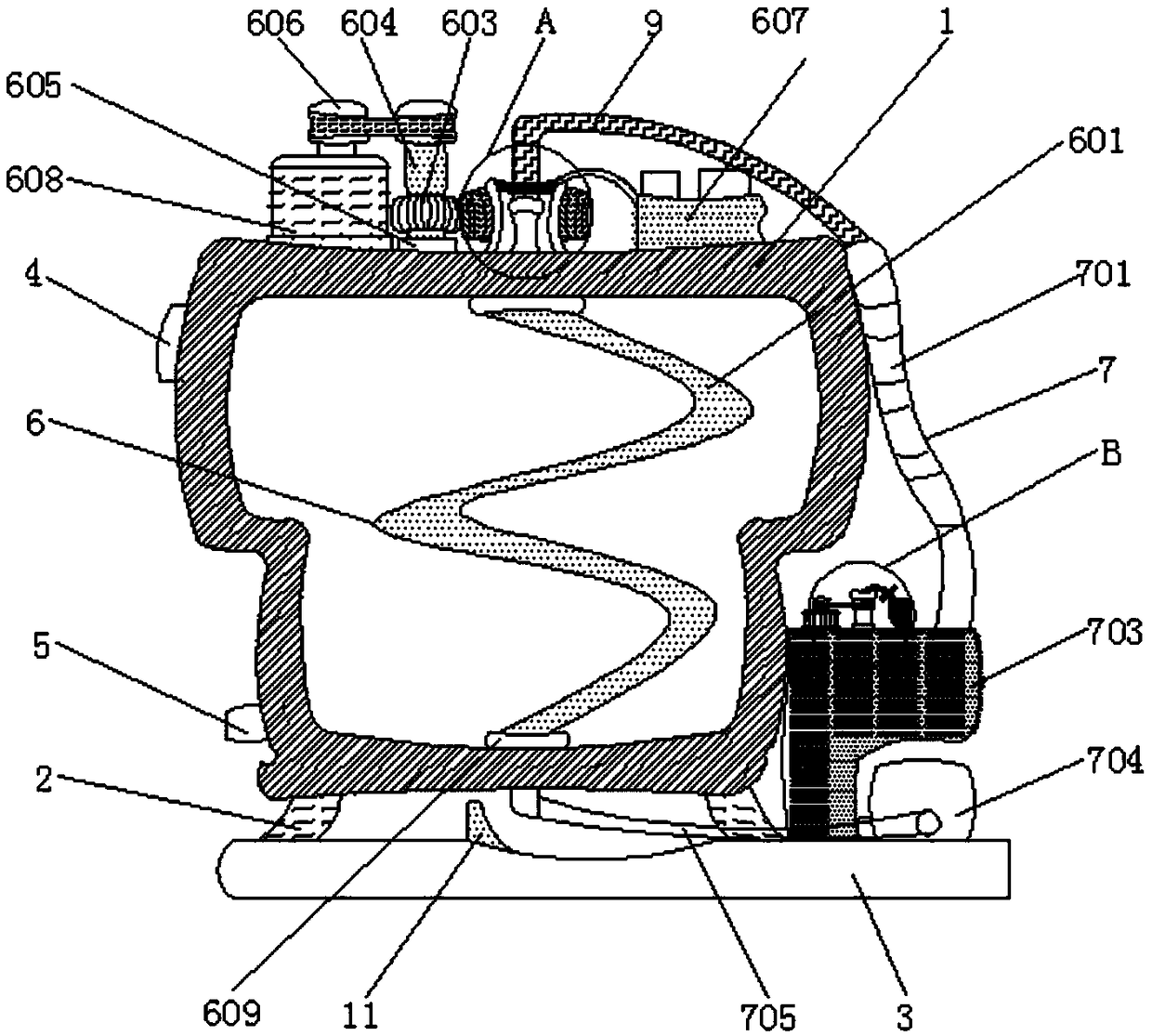

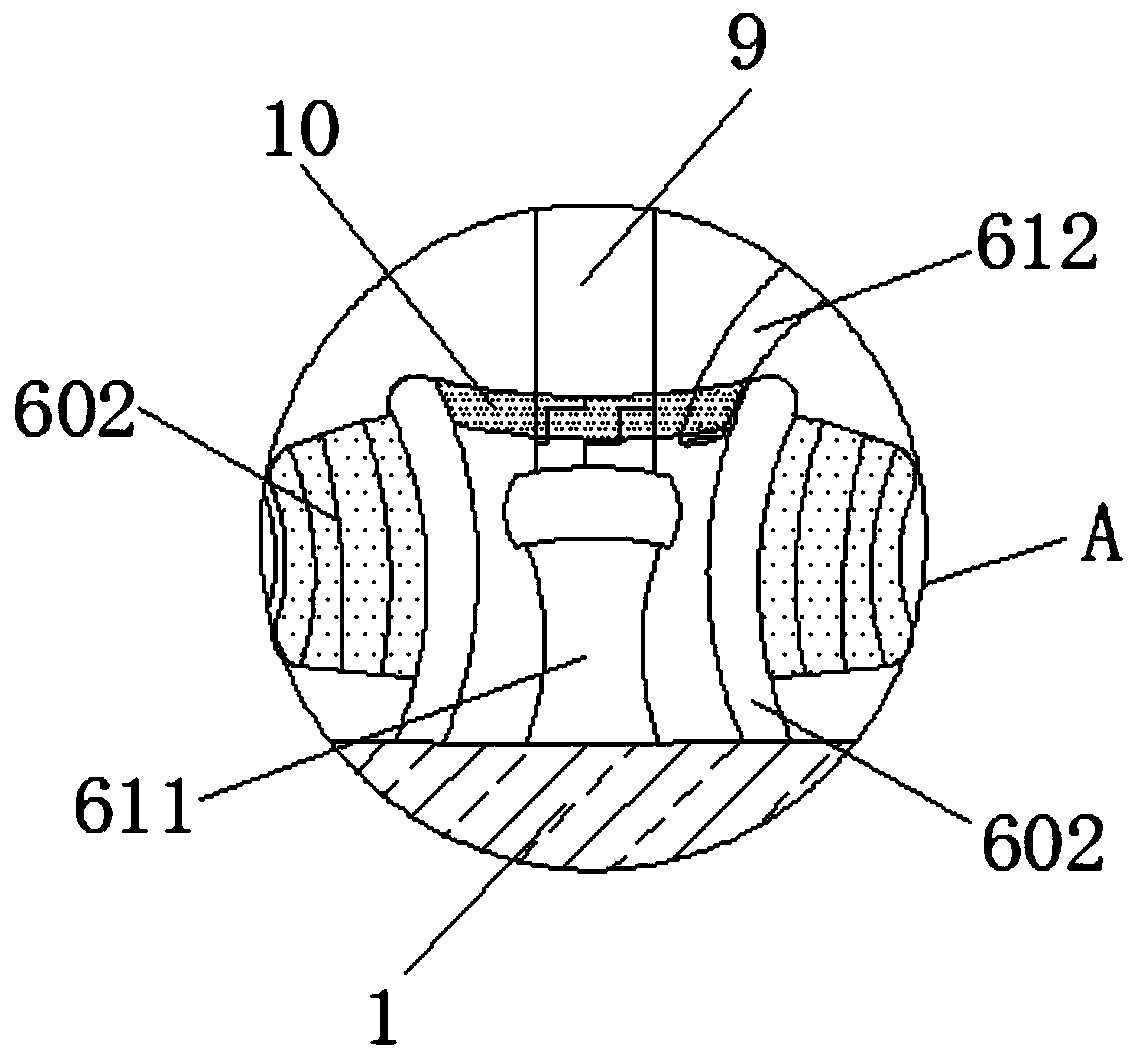

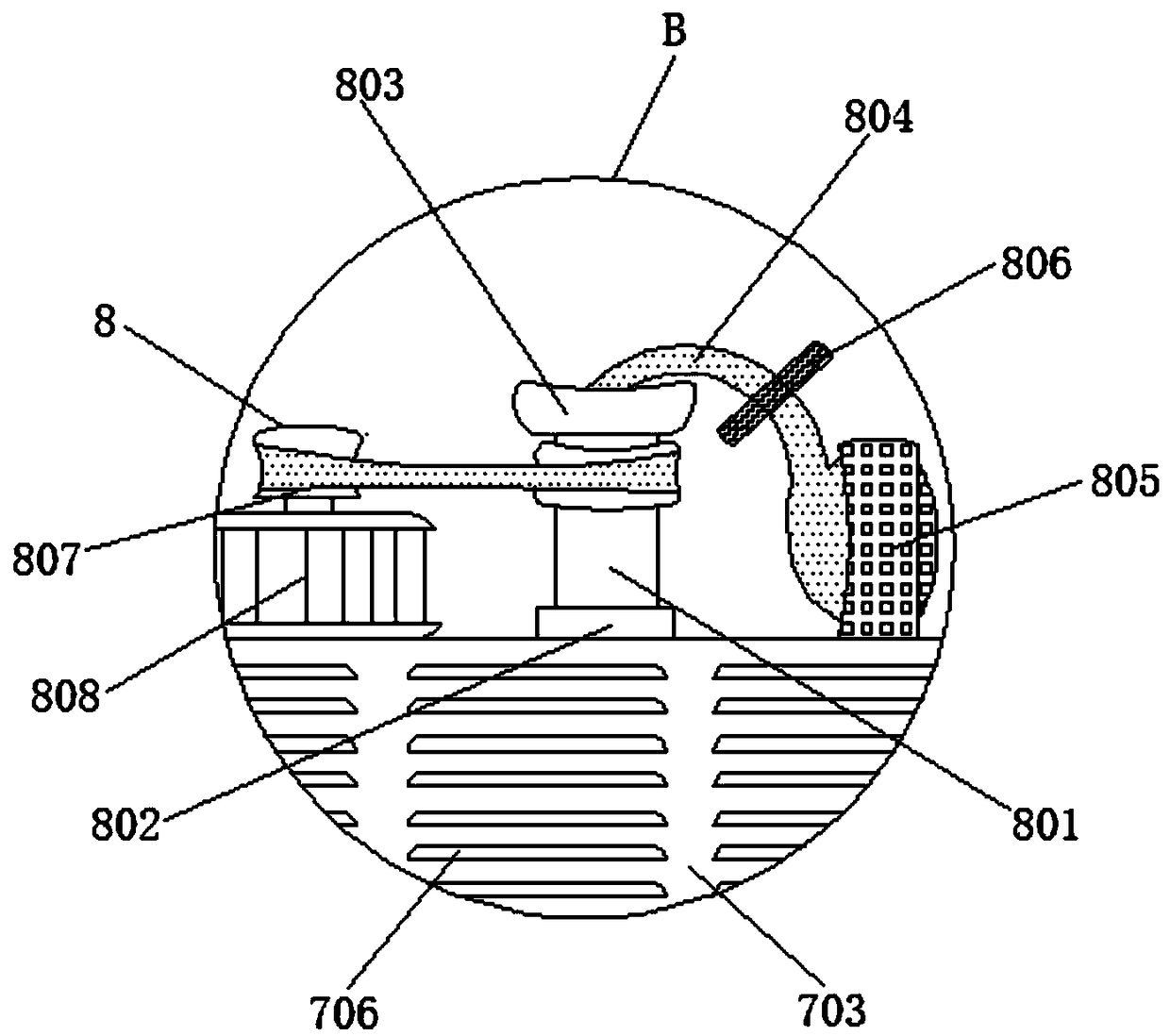

Dairy product cooling device based on water cooling mode

ActiveCN108827030AImprove cooling effectFaster coolingStationary tubular conduit assembliesCold airMotor drive

The invention provides a dairy product cooling device based on a water cooling mode, and relates to the field of dairy product cooling. The cooling device solves the problem that the existing diary product cooling is large in water consumption and poor in cooling effect. The cooling device comprises a cooling box, and the bottom of the cooling box is welded to the top of a base through overhead legs, and the side wall of the cooling box close to the top is provided with a feeding port, and the side wall of the cooling box close to the bottom is provided with a discharging pipe in communication, and a water and air integrated cooling mechanism is arranged inside the cooling box. The cooling device introduces water to a water cooling pipe inside a cooling elbow to promote cooling, and an airpump introduces outside cold air into the cooling elbow through an air guide pipe. A gear motor drives the cooling elbow through a pulley to rotate inside a dairy product to promote uniform temperature reduction of the dairy product and also drive stirring of the dairy product to expose the portion with higher temperature to promote cooling.

Owner:青海雪峰牦牛乳业有限责任公司

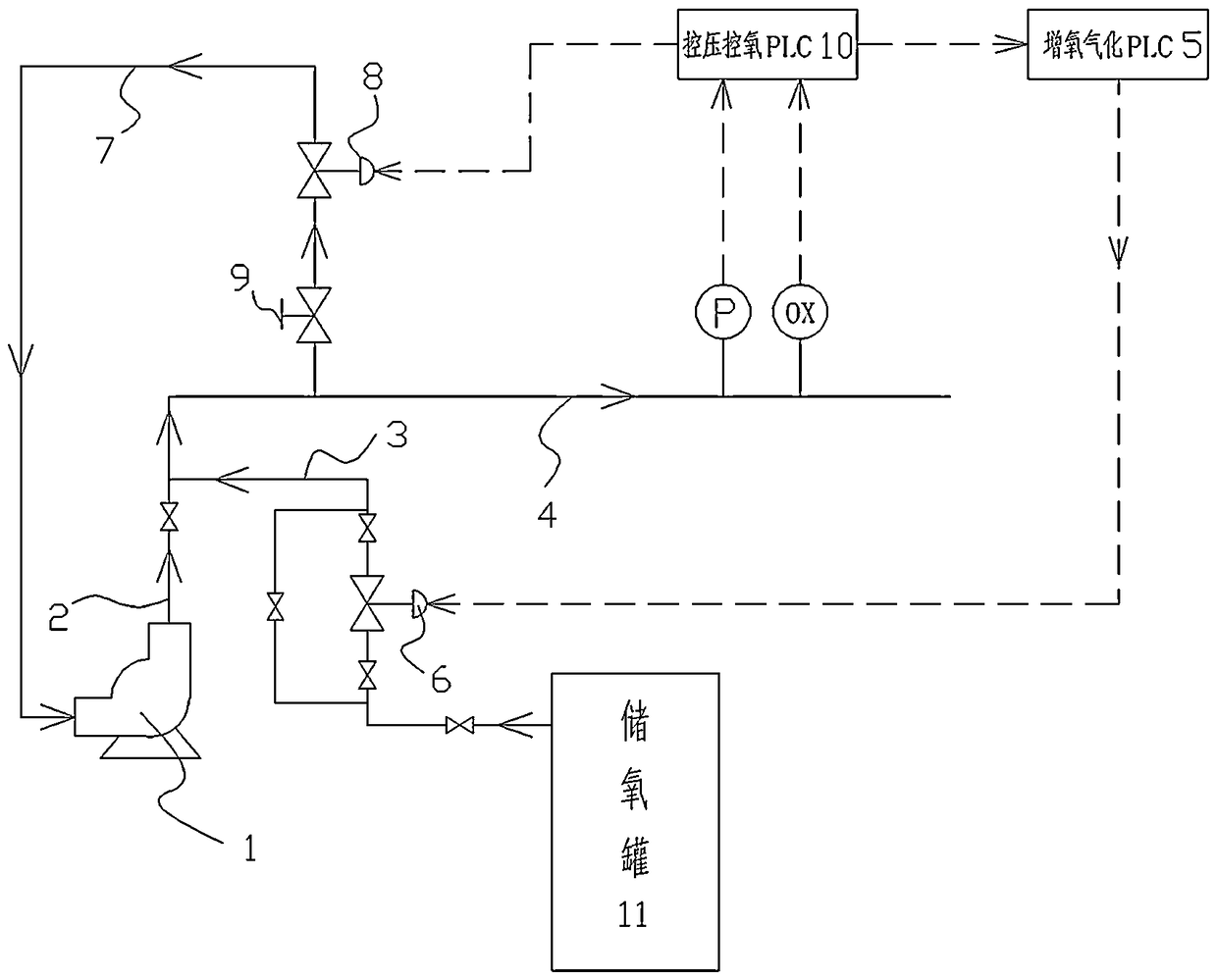

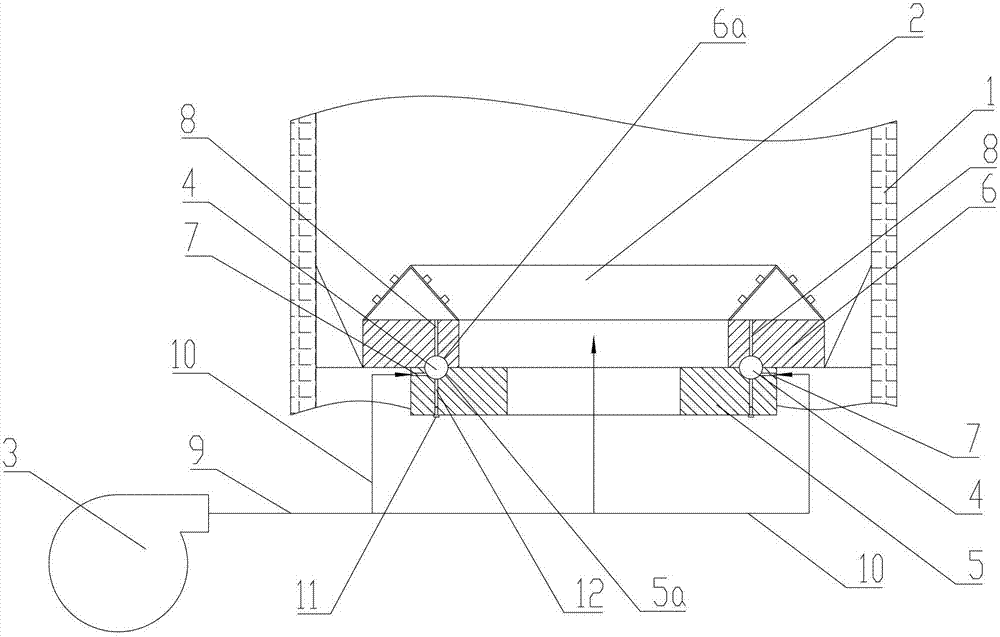

Pressure and oxygen control system for fixed bed aeration gasification process

InactiveCN108264939AReduce supplyReduce wind pressureGasification processes detailsCombustible gas productionControl systemControl signal

The invention discloses a pressure and oxygen control system for a fixed bed aeration gasification process. An outlet of a blast blower is connected with an air output pipe, and an oxygen output pipeis connected with an aeration air main after converging and communicating with the air output pipe; the pressure and oxygen control system comprises an escape pipe and a pressure and oxygen control PLC, one end of the escape pipe communicates with the aeration air main, the other end of the escape pipe is connected to an inlet of the blast blower, and a pipeline of the escape pipe is provided withan escape regulating valve; the aeration air main is provided with an air pressure transmitter and an oxygen analyzer; the air pressure transmitter and the oxygen analyzer are respectively connectedto an input interface of the pressure and oxygen control PLC, and an output interface of the pressure and oxygen control PLC is respectively connected to the escape regulating valve and an aeration gasification PLC; and the pressure and oxygen control PLC controls the opening of the escape regulating valve according to the air pressure and oxygen concentration of the aeration air main and outputsan aeration control signal to the aeration gasification PLC, and the aeration gasification PLC controls an aeration regulating valve, so that the air pressure and oxygen concentration of the aerationair main are kept stable.

Owner:ANHUI JINGHE IND

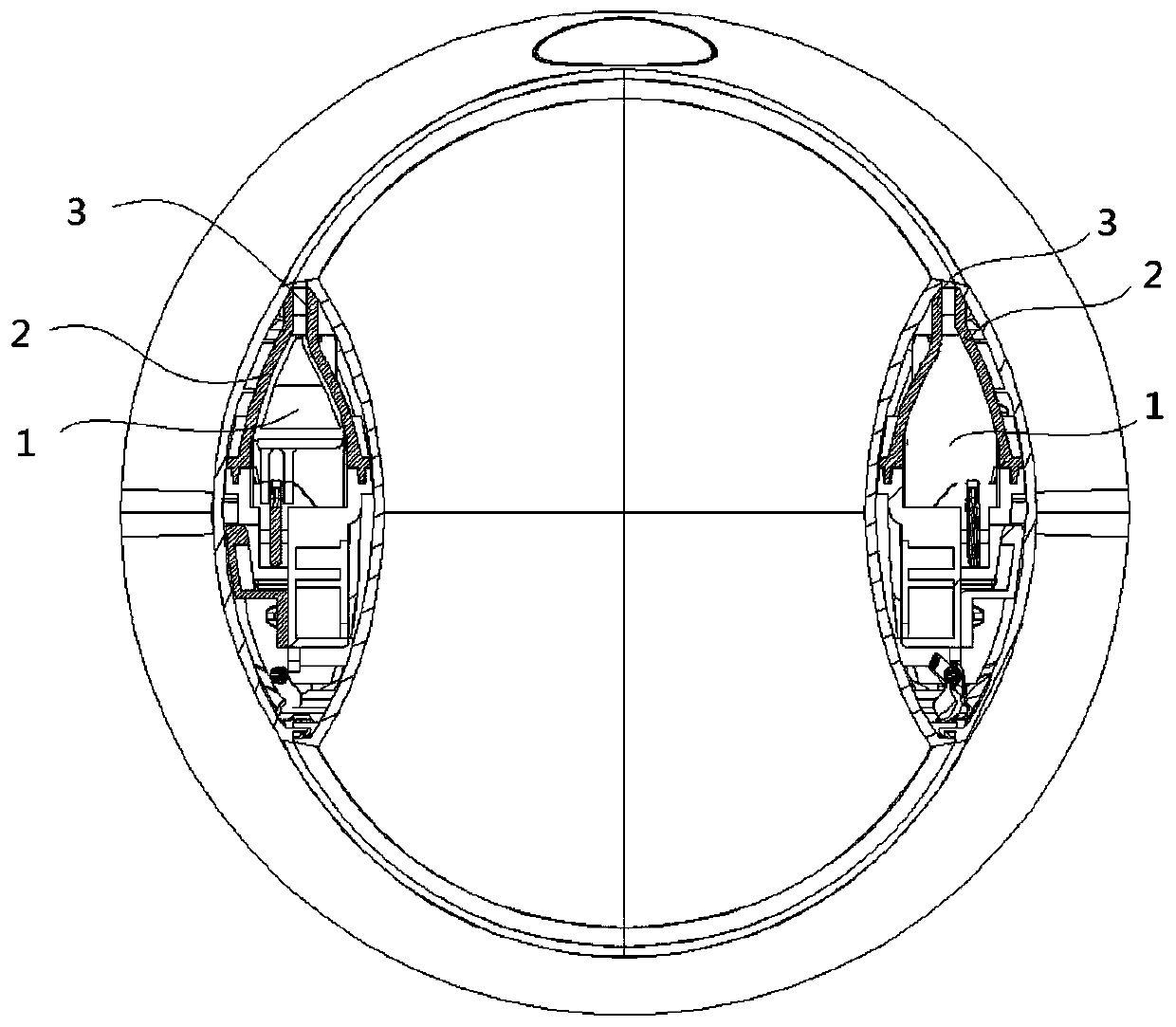

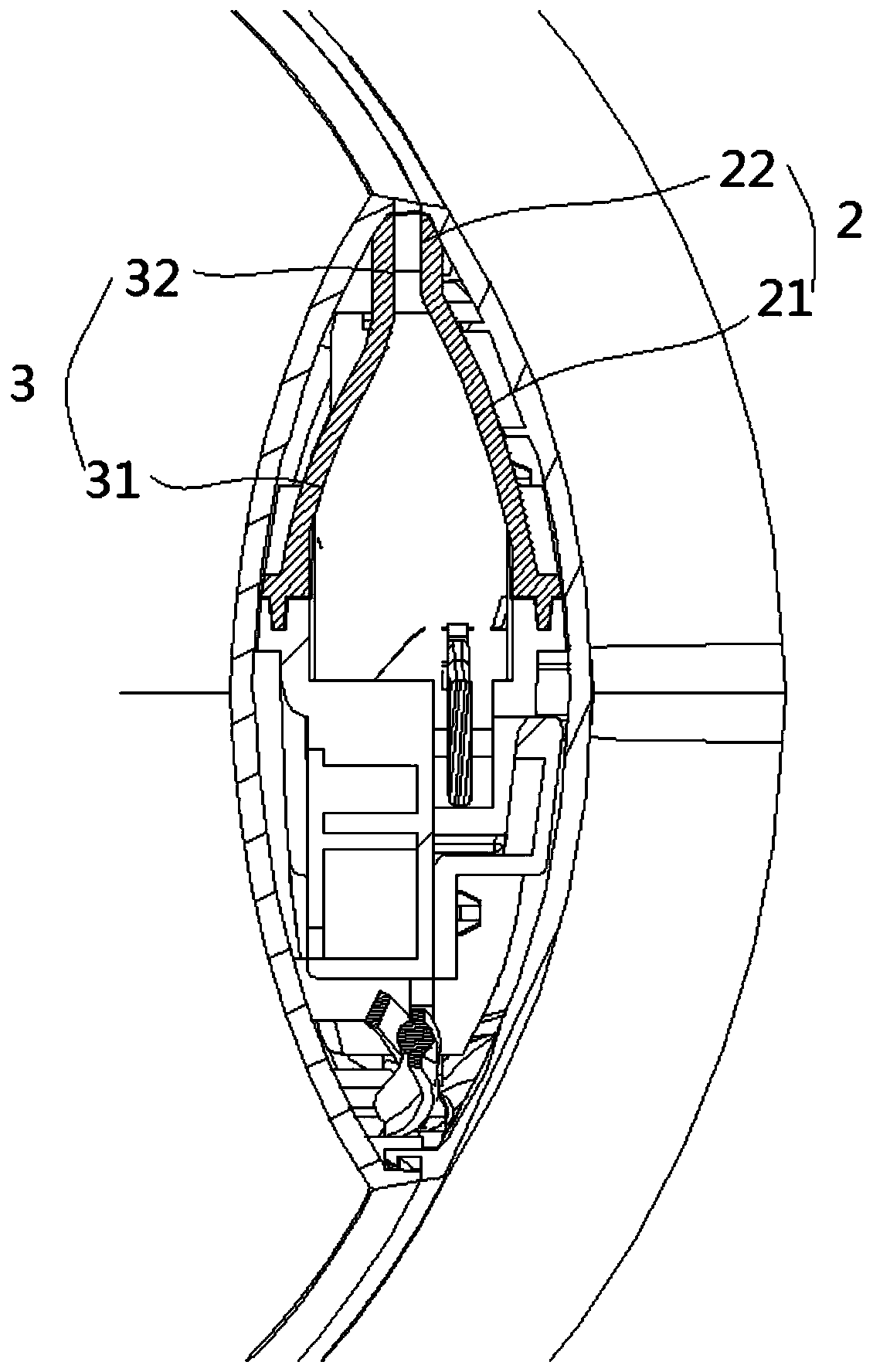

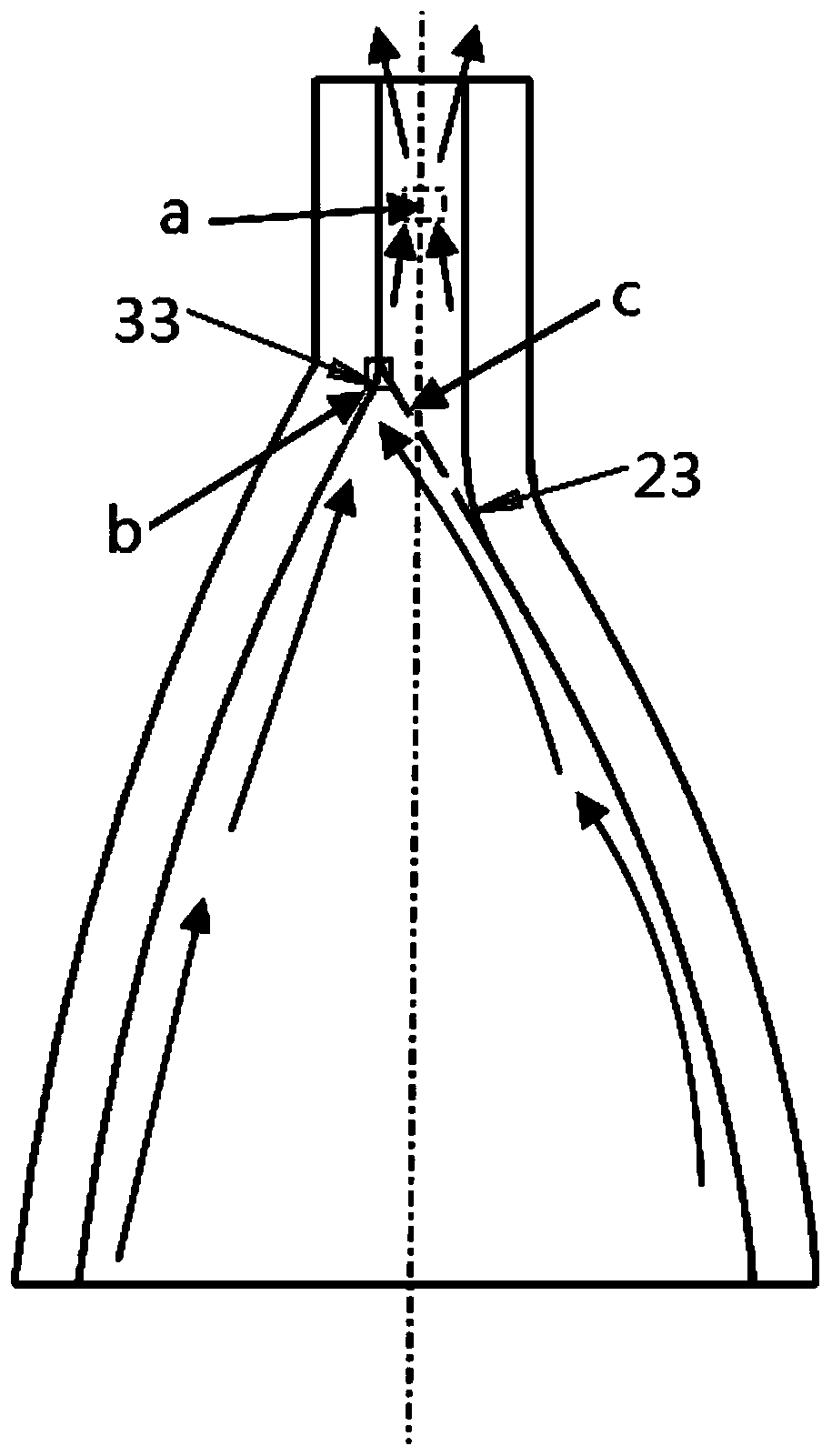

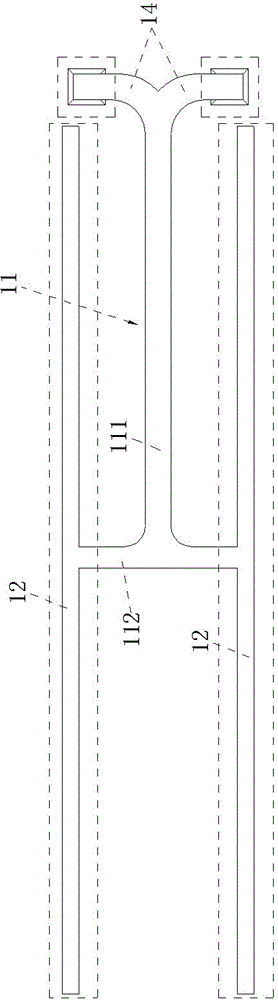

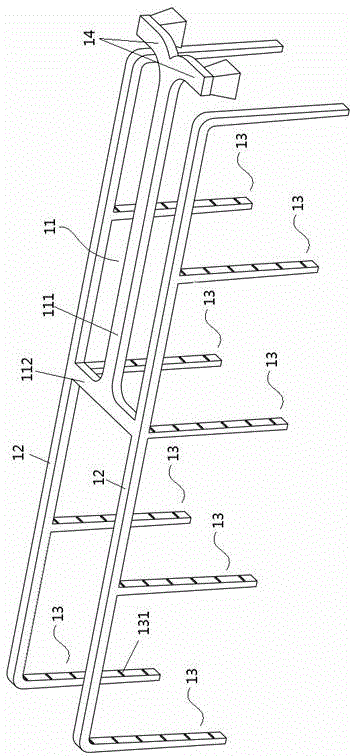

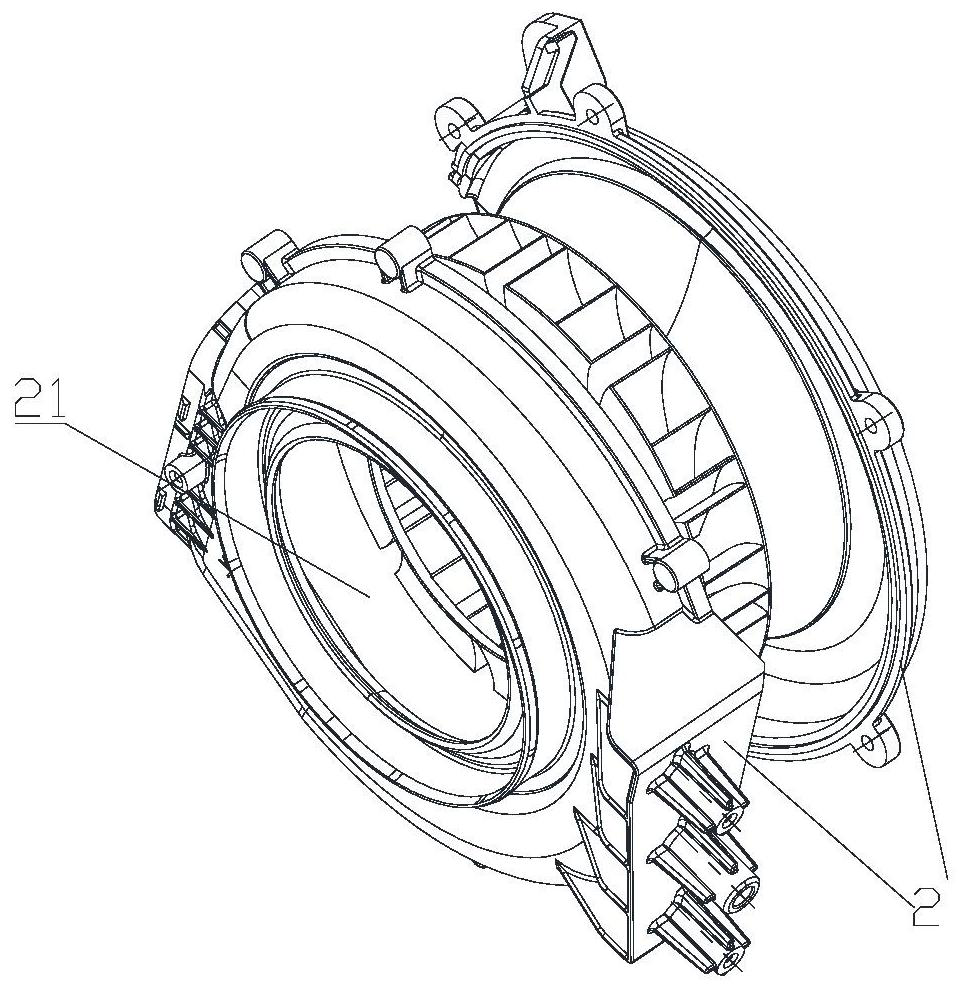

Handpiece assembly, air duct system and fan

The invention provides a handpiece assembly, an air duct system and a fan. The handpiece assembly comprises an air outlet duct and air guide plates; the air outlet duct is divided into a plurality ofair outlet parts by the multiple air guide plates, and each air outlet part is provided with a first air wall and a second air wall which are arranged opposite to each other; each first air wall comprises a first arc-shaped flow guide surface and a first flow outlet surface which is connected to the first arc-shaped flow guide surface in the air flow direction; each second air wall comprises a second arc-shaped flow guide surface and a second flow outlet surface which is connected to the second arc-shaped flow guide surface in the air flow direction; an air outlet gap is formed between each first flow outlet surface and the corresponding second flow outlet surface; and in the air flow direction, the extension surfaces of the first arc-shaped flow guide surfaces intersect at the second flowoutlet surfaces, and the extension surfaces of the second arc-shaped flow guide surfaces intersect at the first flow outlet surfaces. The handpiece assembly is high in air outlet volume and air pressure.

Owner:GREE ELECTRIC APPLIANCES INC

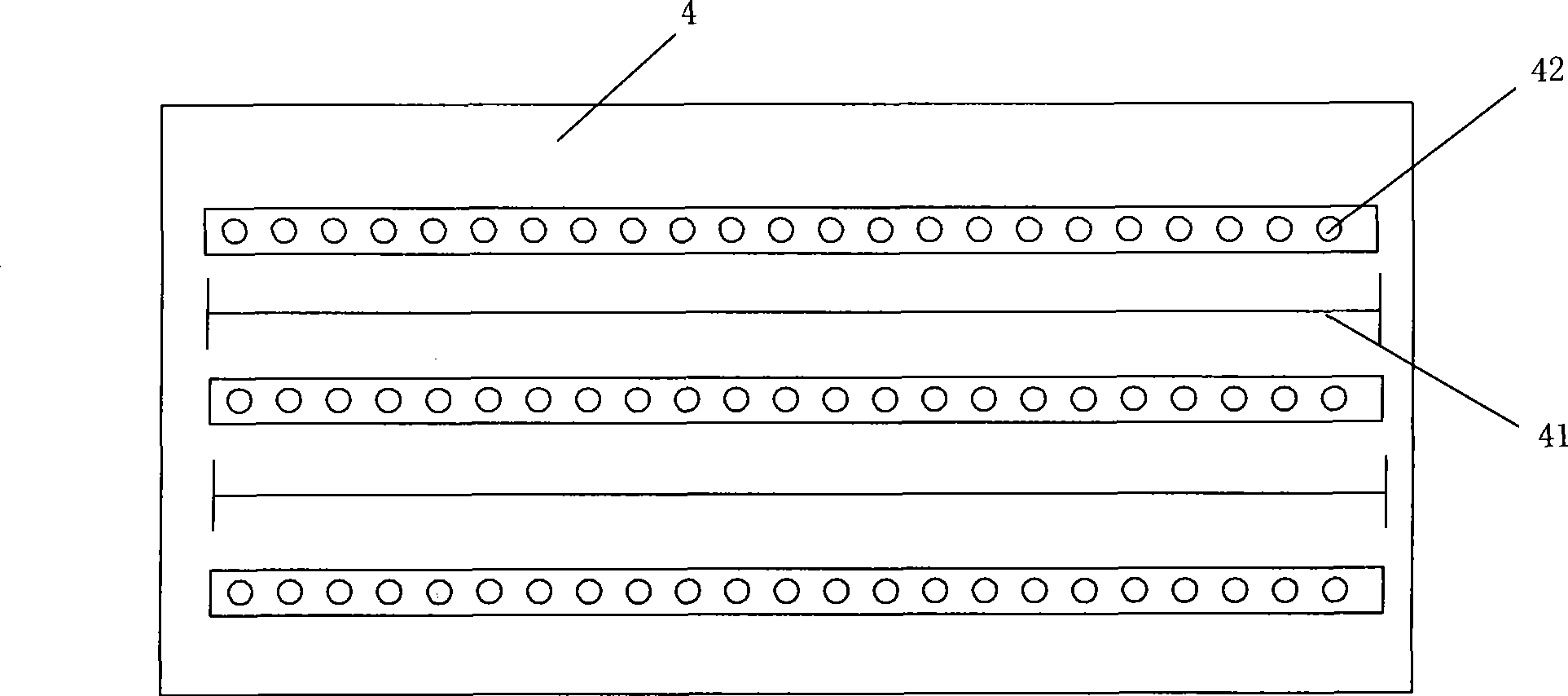

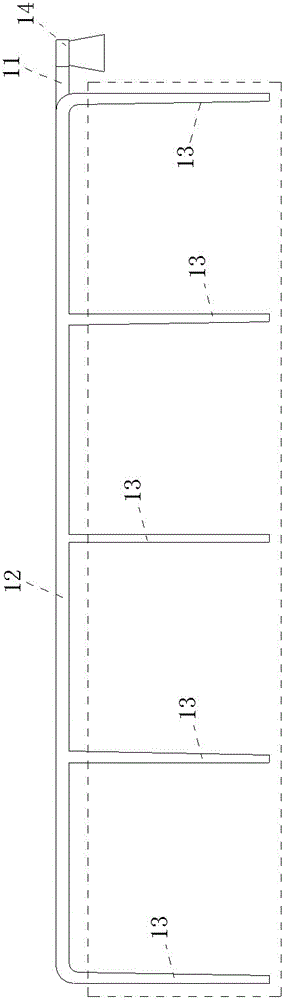

Energy storage cabin air duct system and energy storage cabin with air duct system

ActiveCN104943531AGuaranteed performance and temperature control effectSame wind speedElectric propulsion mountingPropulsion coolingElectrical energy storageElectric energy

The invention relates to the field of electrical energy storage cabins, in particular to an energy storage cabin air duct system and an energy storage cabin with the air duct system. The energy storage cabin air duct system comprises a main air duct and two or more branch air ducts. The main air duct is provided with an air inlet and an air outlet communicated with the branch air ducts. The branch air ducts are divided into far-end branch air ducts and near-end branch air ducts from far to near according to the distance between the branch air ducts and the air inlet of the main air duct, the number of the far-end branch air ducts is at least one, and the cross sections of the far-end branch air ducts are gradually reduced from the end close to the main air duct to the other end. Due to the fact that the branch air ducts of the energy storage cabin air duct system are divided into the far-end branch air ducts and the near-end branch air ducts from far to near according to the distance between the branch air ducts and the air inlet of the main air duct and the cross sections of the far-end branch air ducts are gradually reduced from the end close to the main air duct to the other end, air pressure in the far-end branch air ducts can be maintained easily, it is promoted that the air outflow speeds of the branch air ducts are kept roughly the same, and finally the performance and the temperature control effect of a temperature control system of an energy storage device are guaranteed.

Owner:XJ ELECTRIC +2

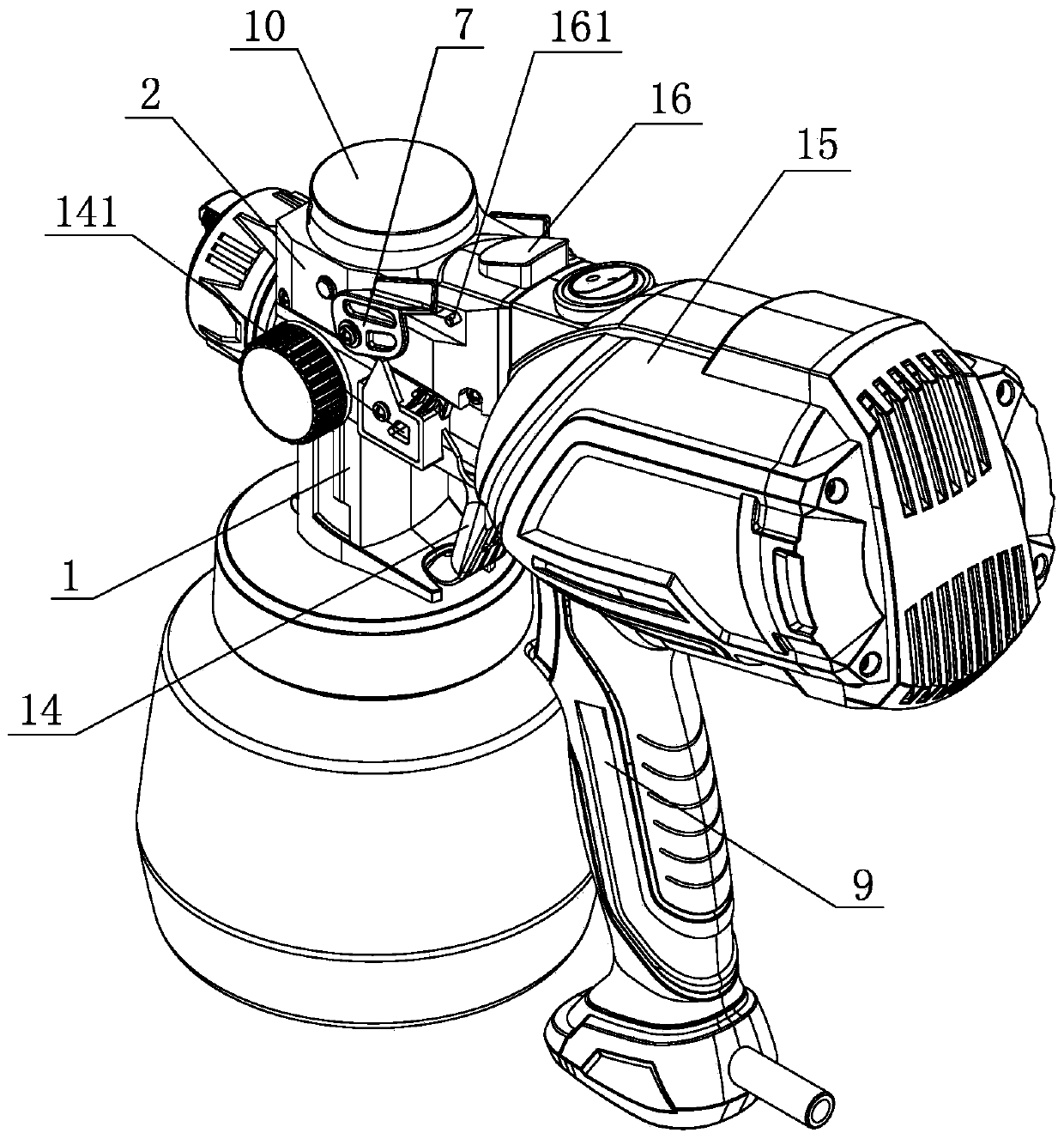

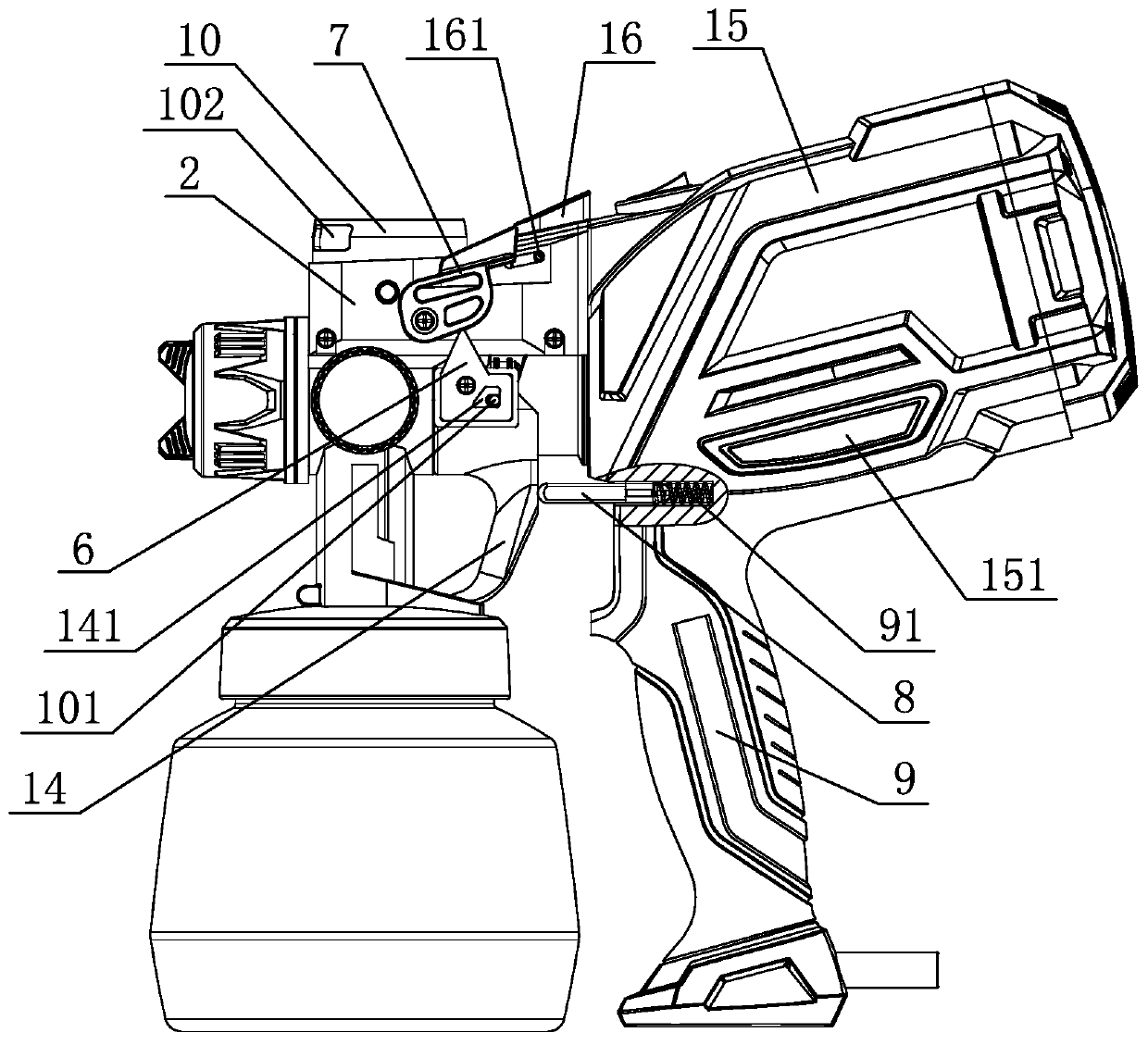

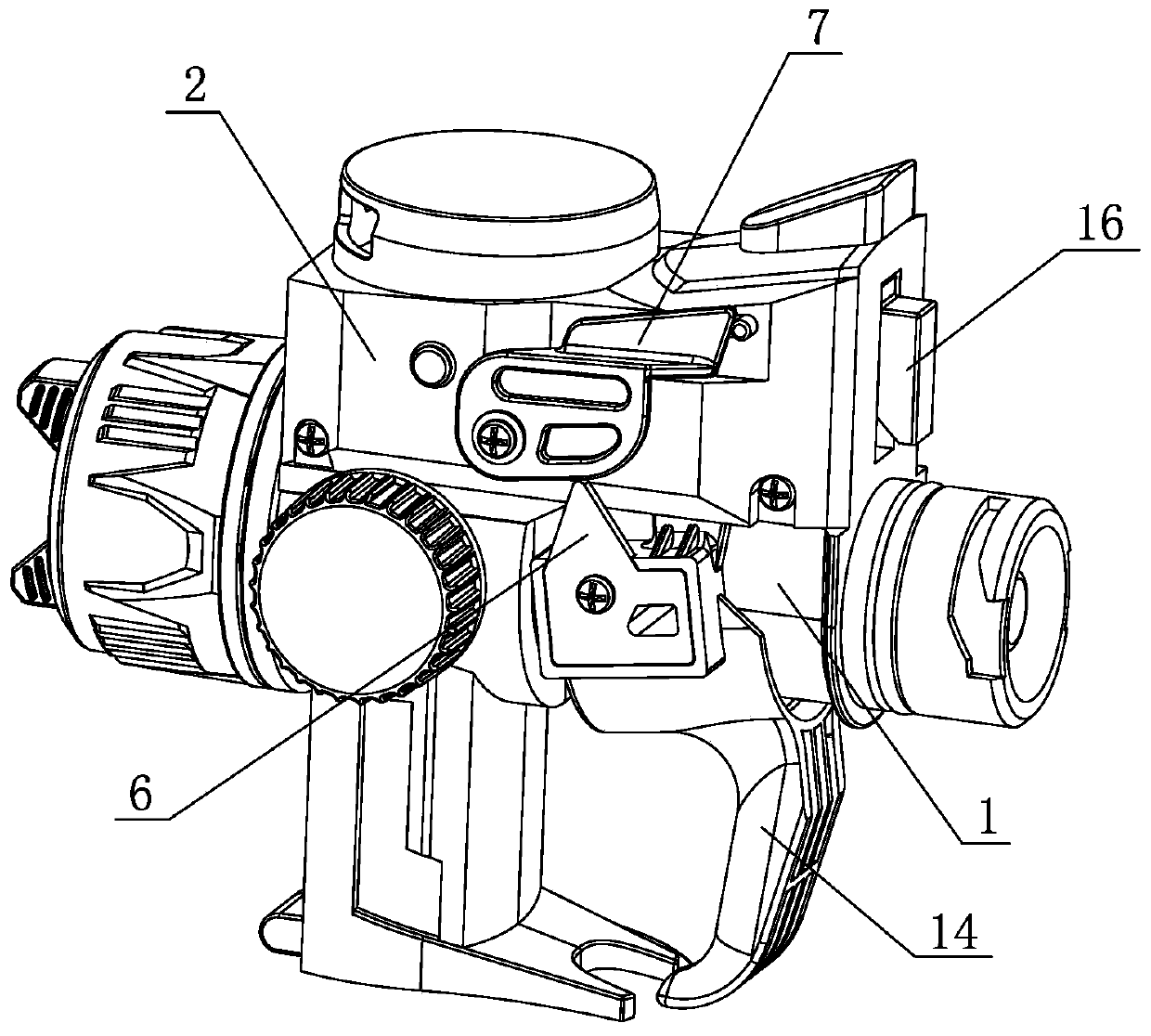

Electric spray gun

PendingCN110665672AImprove cooling effectFeel comfortableLiquid spraying apparatusPhysicsEngineering

The invention discloses an electric spray gun which comprises a front gun body for mounting a valve rod and is characterized in that an auxiliary air outlet is formed in the front gun body; the auxiliary air outlet and an air outlet in the front end of the gun body are independent from each other; the auxiliary air outlet communicates with an air channel in the front gun body; and an air outlet opening and closing control mechanism is arranged on the auxiliary air outlet. The electric spray gun has the following advantages: the auxiliary air outlet in the front gun body is independent from theair outlet in the front end; and when spraying of the electric spray gun finishes, the air outlet opening and closing control mechanism is opened to discharge heat gathered in the gun body out of theauxiliary air outlet along with the air, so that the radiating effect is greatly improved, the surface temperature of the gun body is lowered, the service life of the spray gun is prolonged, and thecharacteristic of spraying liquid is not damaged or changed.

Owner:宁波市康欣机电有限公司

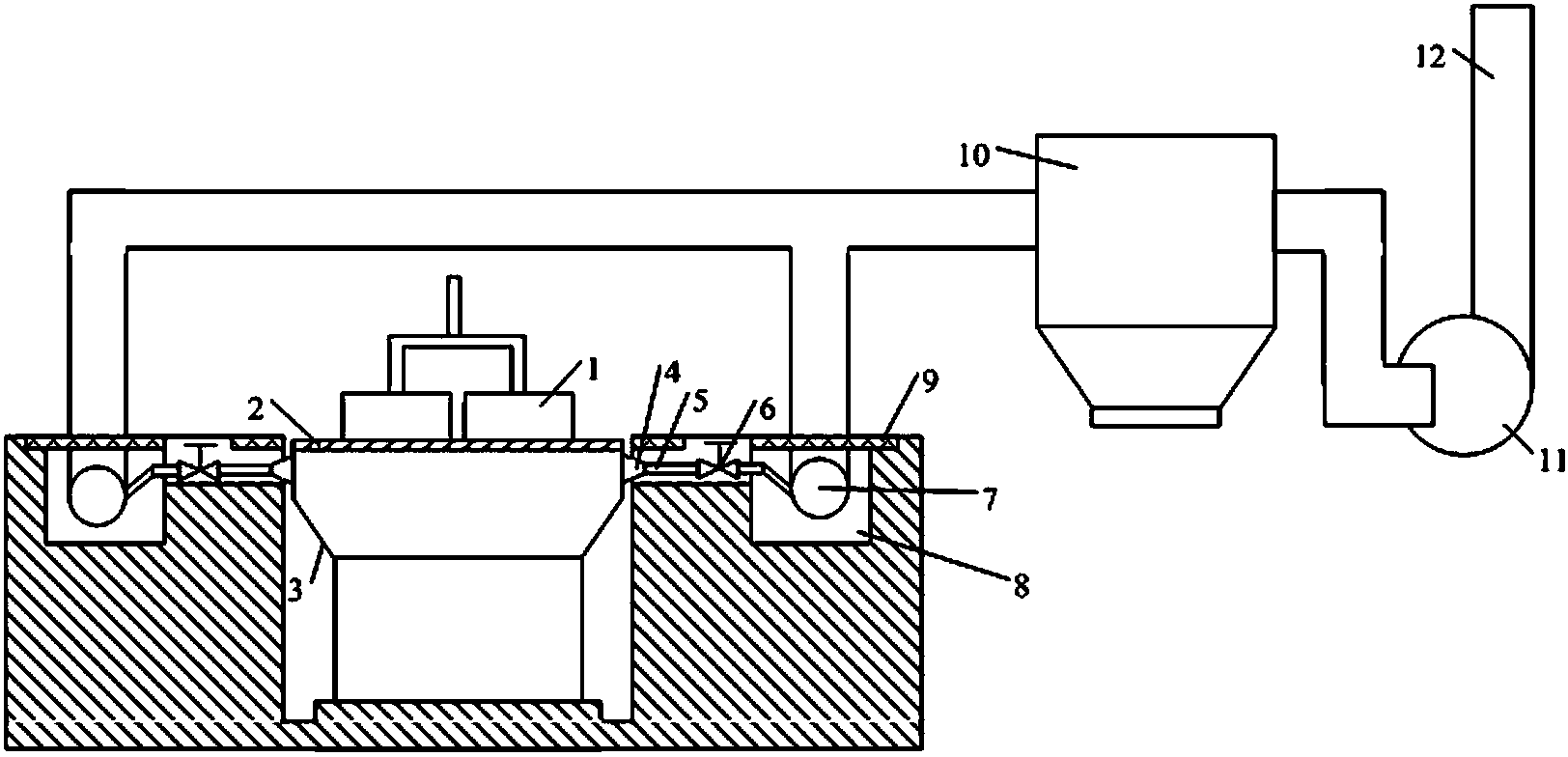

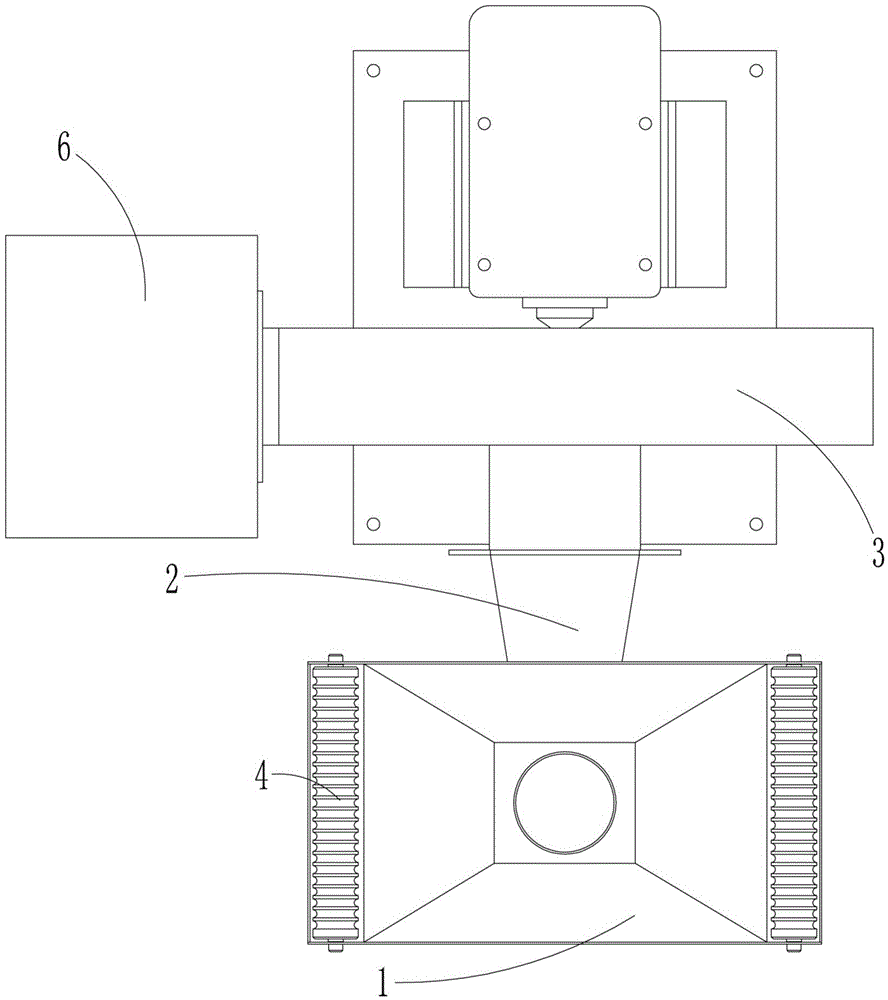

Dust recovery system of electrolyte manual cleaning workshop section

InactiveCN103586251AGuaranteed wind pressureGuaranteed to control the wind speedDispersed particle filtrationDirt cleaningProcess systemsWorking environment

Provided is a dust recovery system of an electrolyte manual cleaning workshop section. The dust recovery system of the electrolyte manual cleaning workshop section comprises feeding hoppers, a bag filler, a centrifugal fan, dust removal air pipes and exhaust hoods, wherein the independent feeding hoppers are assembled below feeding grids of stations of the electrolyte manual cleaning workshop section respectively, openings are formed in the two opposite sides of the upper portion of each feeding hopper, each opening is communicated with the corresponding exhaust hood, the exhaust hoods arranged on the same sides of the feeding hoppers are communicated with the dust removal air pipes respectively, the two dust removal air pipes are communicated with an air inlet of the bag filler at the same time, and an air outlet of the bag filler is communicated with an inlet of the centrifugal fan. According to the dust recovery system of the electrolyte manual cleaning workshop section, the dust removal technology is applied to working places where closed exhaust hoods cannot be arranged, effective control over dust of a manual operation place is achieved, the working environment required by an existing process system is ensured, the dual-purpose effect is achieved, and the dust recovery system of the electrolyte manual cleaning workshop section has good application prospect.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

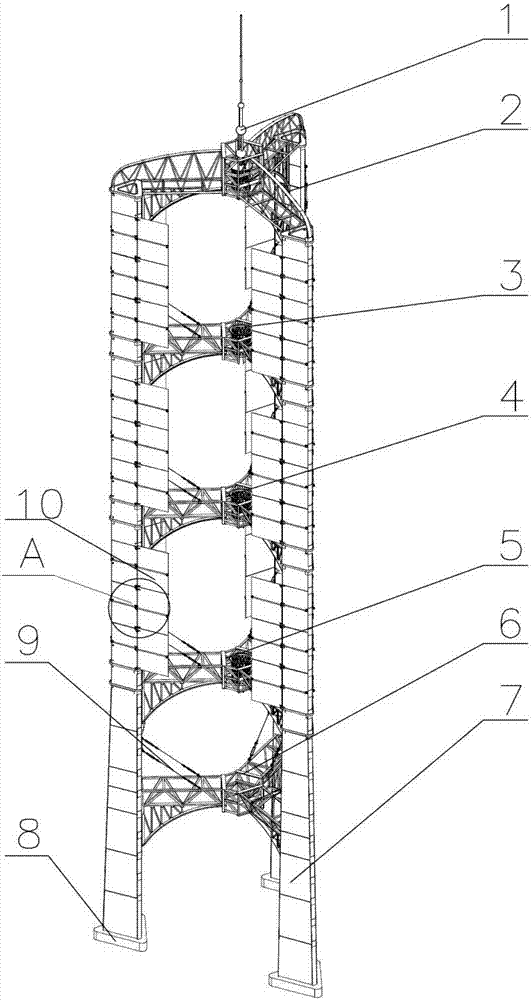

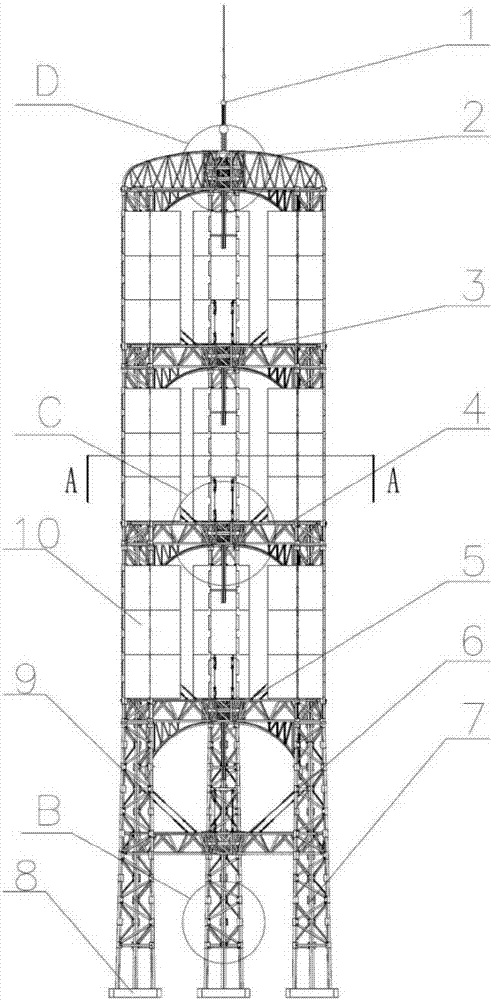

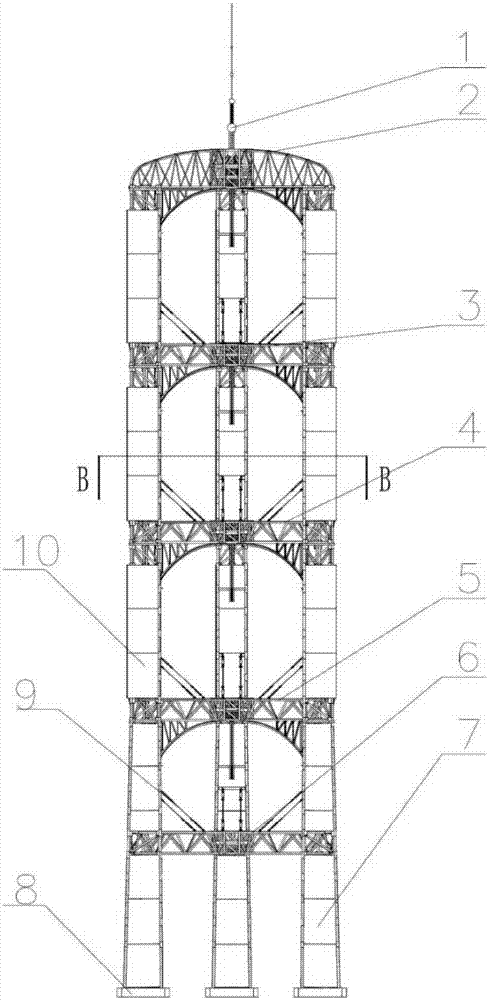

Multi-point support frame structure for integrated narrow-pipe wind-collecting power-generation system

ActiveCN107387331AReduce wind pressureGuaranteed wind pressureWind motor controlWind motor supports/mountsLightning rodTower

The invention relates to a multi-point support frame structure for an integrated narrow-pipe wind-collecting power-generation system. The structure includes a plurality of supporting tower legs, and installation space defined by the supporting tower legs is internally provided with a plurality of supporting assemblies, for installing pipe barrels, from top to bottom; the top of each supporting tower leg is connected with the end, extending outward, of a tower top, and the tower top is also provided with a tower top supporting platform; the tower top supporting platform is provided with a lightning rod. The multi-point support frame structure is simple and convenient to use, and a stacked tower frame structure from bottom to top can be achieved through the supporting tower legs; the multi-point support frame structure has an overall height of 50-350 m or more, and in the extension range of the lazy arm of a crane and the tolerance range of the material strength, the multi-point support frame structure can achieve maximum adjustment of the height.

Owner:李勇强

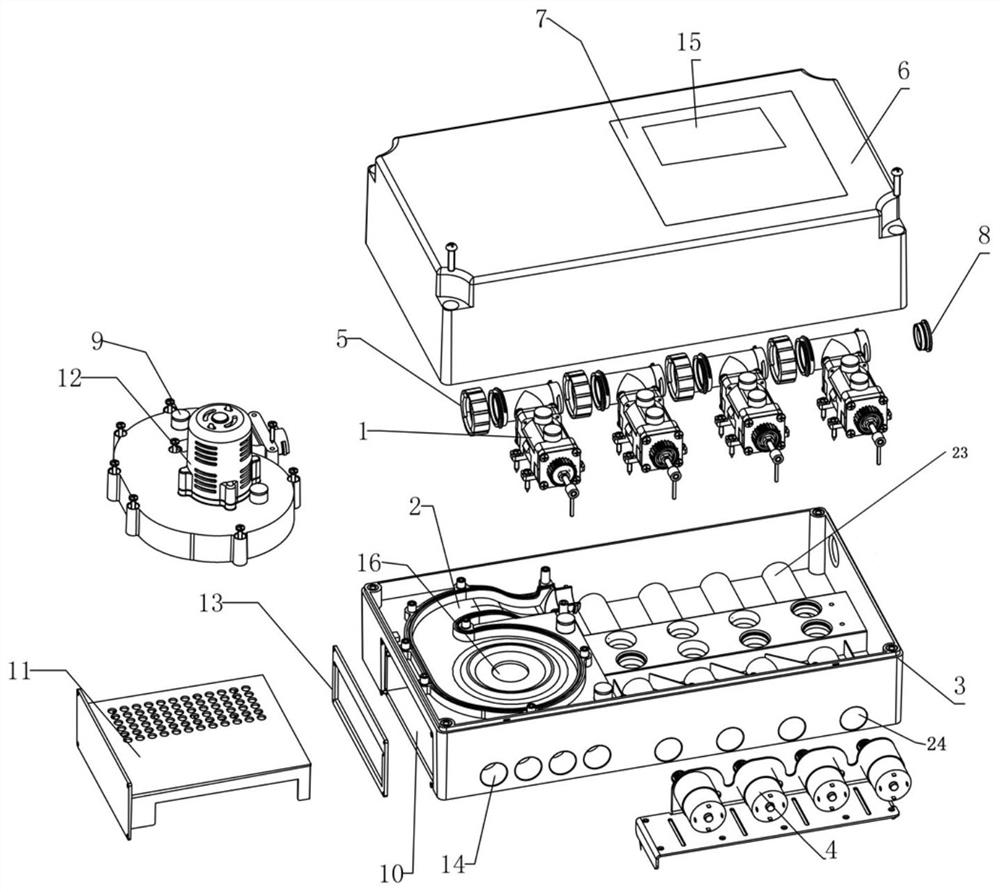

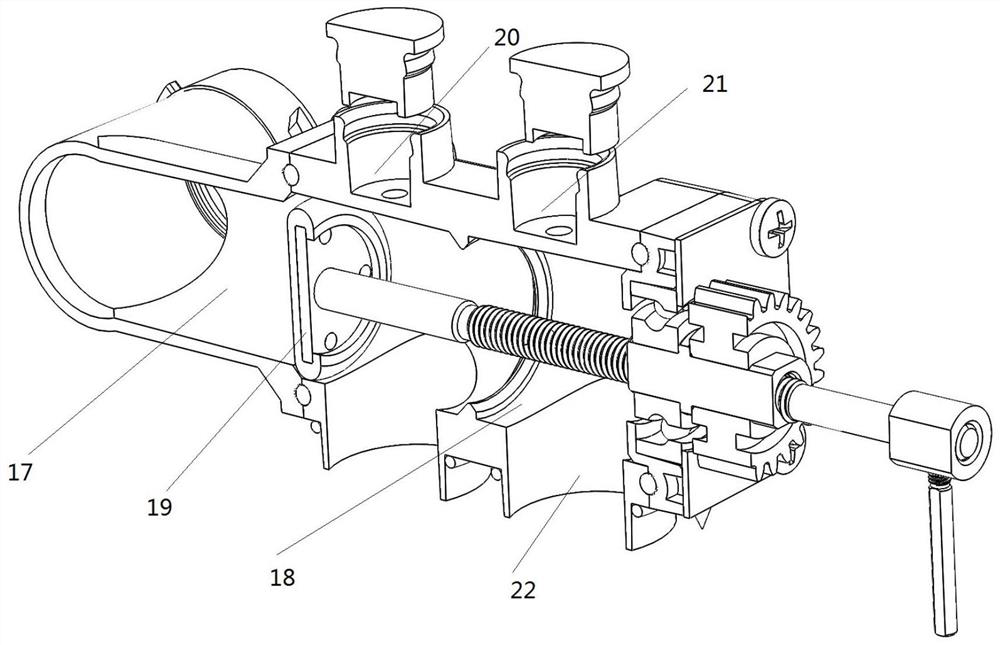

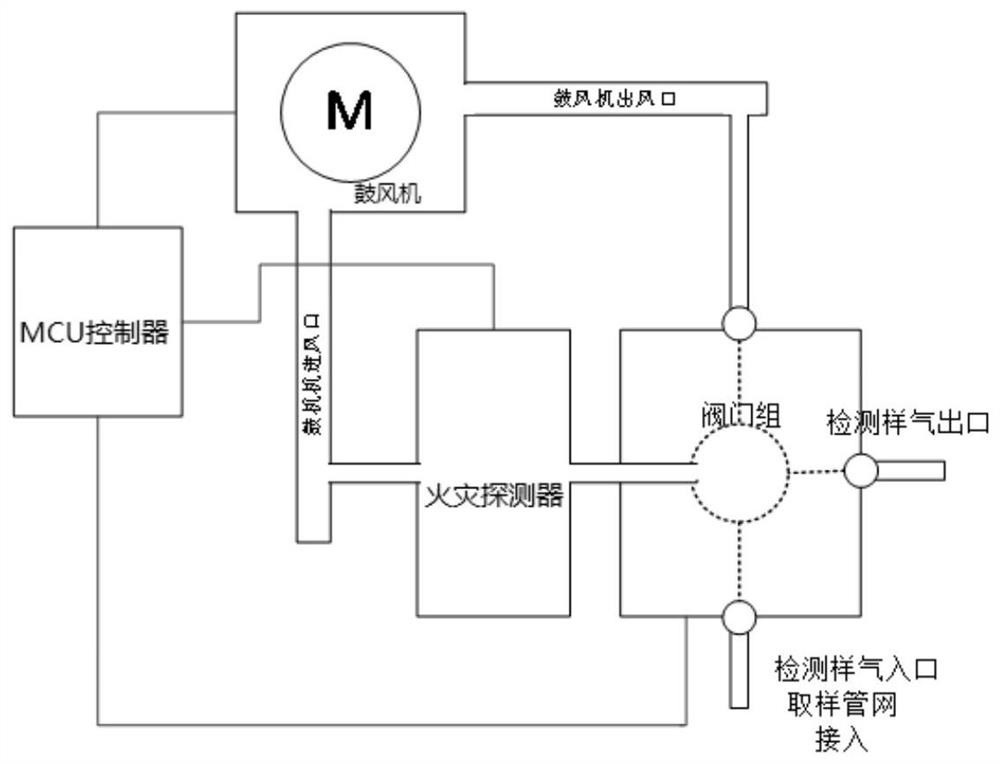

Self-cleaning air sampling alarm device and working method thereof

PendingCN112309072AEasy accessDoes not affect power supplyHollow article cleaningParticle suspension analysisFire detectorAutomatic control

The invention discloses a self-cleaning air sampling alarm device which comprises a valve assembly, a fan assembly, a base, a driving motor, a valve group coupler and an MCU controller integrated on aPCB, the fan assembly is communicated with one end of the valve assembly through the valve group coupler, and the other end of the valve assembly is provided with a plug. The fan assembly is used forproviding sample gas flow with stable wind pressure, the valve assembly is used for realizing multipath sampling detection feedback results, and the MCU controller is used for receiving and feeding back instructions to realize automatic control. The device has the beneficial effects that the structure is simple, the wind speed loss is good, pipe network cleaning and pressurizing functions can beswitched, during normal work, a high-pressure air inlet of the air blower is cut off, and the air suction type fire detector on the pipe network is prevented from being damaged; during cleaning, the air blower sucks air through the air filter and outputs high-pressure clean air; and during pressurization work, the sensitivity of the air-breathing fire detector can be improved.

Owner:YUNNAN HUOFENGHUANG FIRE TECH

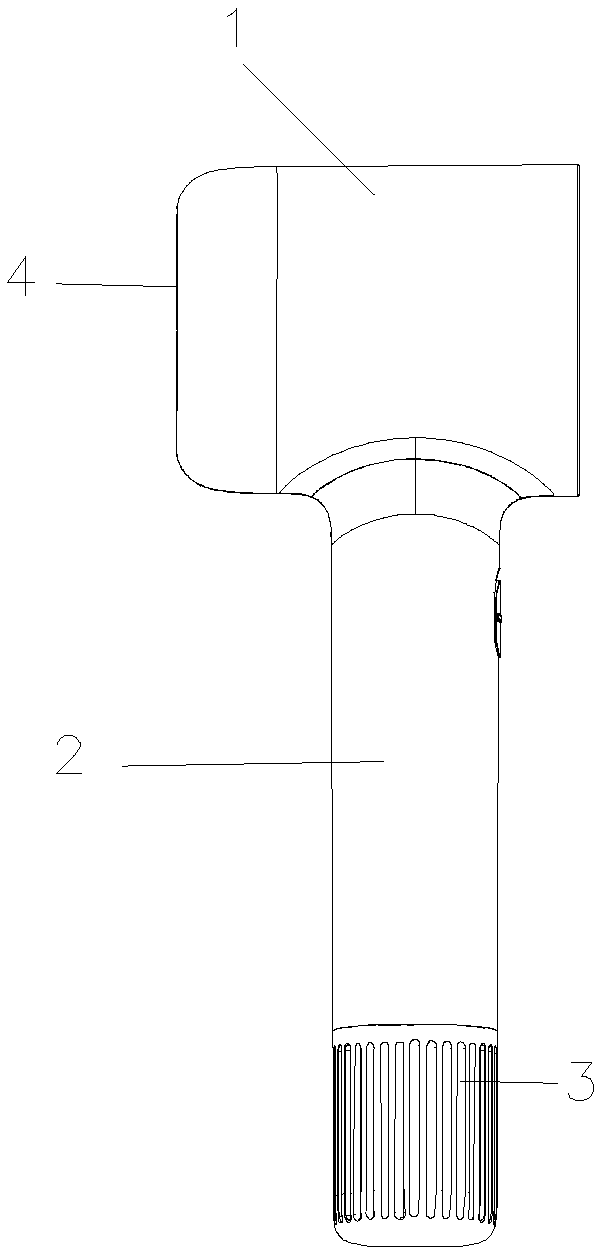

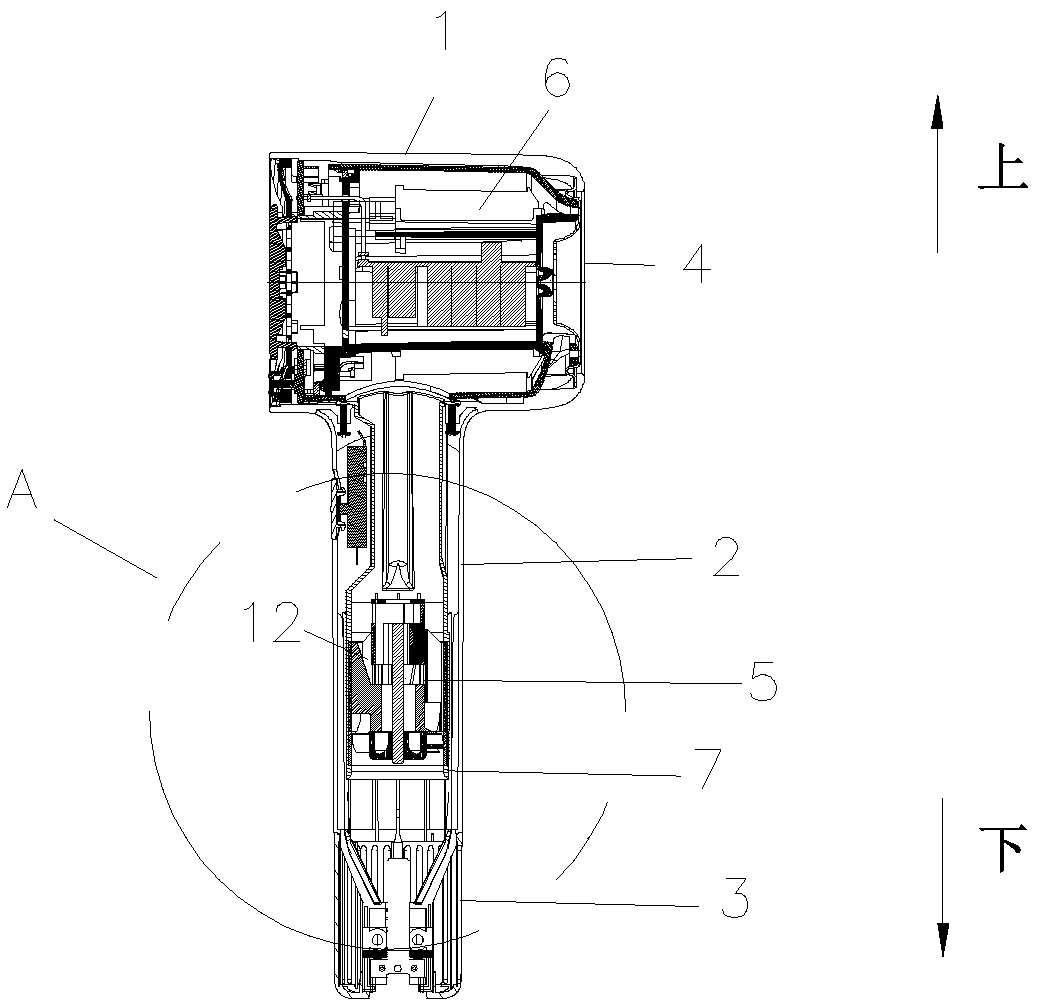

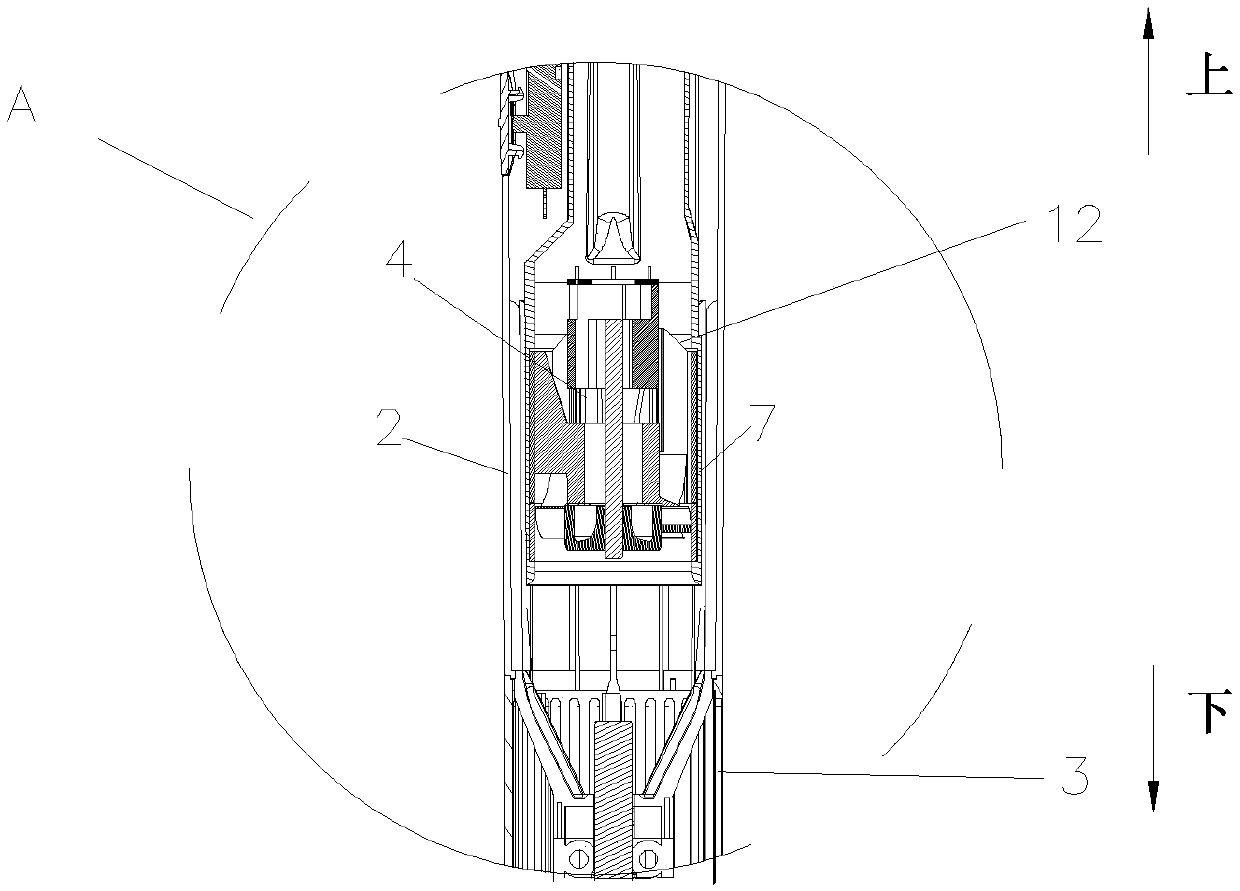

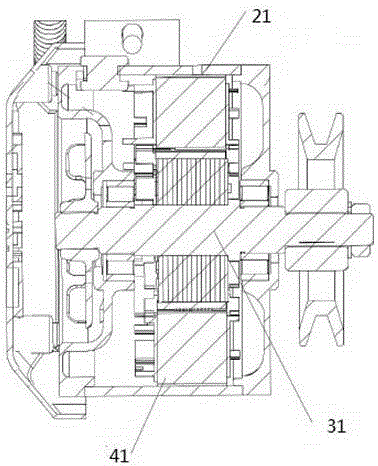

High-speed electric hair drier

The invention relates to the field of household appliances, and the problems that an electric hair drier is large in size and air volume and air pressure are lost are solved. The present invention especially relates to a high-speed electric hair drier. The high-speed electric hair drier comprises a shell, a handle assembly connected with the shell, an air inlet, an air outlet, a fan unit used forsucking air flow into the electric hair drier from the air inlet, and a heating unit used for heating the air flow. The fan unit comprises fan blades and a motor used for driving the fan blades to rotate, the motor comprises a stator assembly and a rotor assembly, and the motor further comprises a support used for supporting the rotor assembly and the stator assembly. The rotor assembly is connected with the fan blades and drives the fan blades to rotate; the support comprises a first cylinder used for supporting the rotor assembly and a second cylinder used for containing the fan blades. Thefirst cylinder is arranged on one side of the second cylinder and is connected with the second cylinder through a connecting blade; the electric hair drier further comprises an air guide pipe, the second cylinder comprises an air inlet side and an air outlet side, and the fan blades rotate to enable airflow to enter the second cylinder from the air inlet side and enter the air guide pipe from theair outlet side.

Owner:LESHOW ELECTRONICS TECH CO LTD

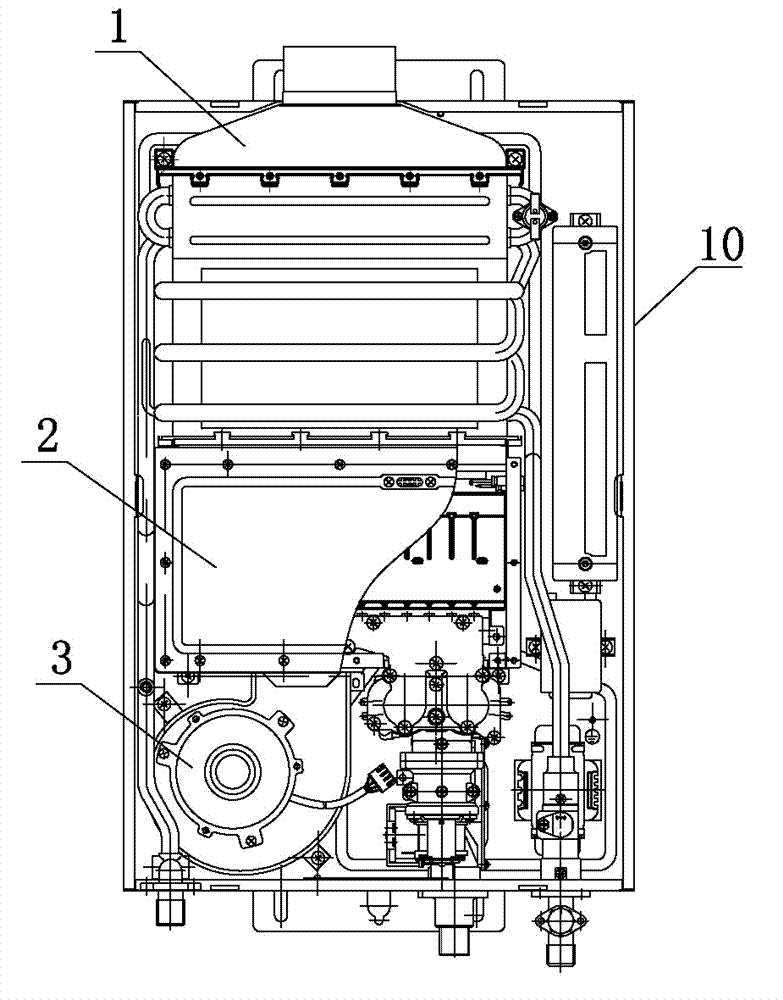

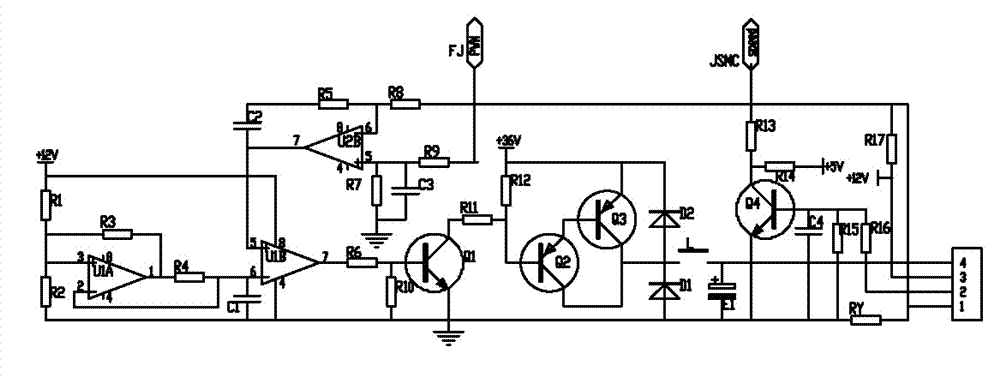

Automatic following control circuit for fan

InactiveCN102878096ATo combustion conditionsChieve protectivePump controlNon-positive displacement fluid enginesMicrocontrollerControl signal

The invention provides an automatic following control circuit for a fan, which comprises a level conversion circuit of a controller, a triangular wave generation circuit, an amplifier U1A for generating triangular waves, a pulse width modulation circuit and a singlechip microcomputer to send control signals in form of pulse width modulation. The control signals are transmitted by a smooth circuit consisting of resistors R7 and R9 and a capacitor C3 to a pin 5 of an amplifier U2B to enable a pin 7 of the U2B to generate corresponding control level which is transmitted to a pin 5 of the UIB, and to enable the pin 7 of the UIB to generate corresponding pulse width modulation square waves and triangular waves generated by the U1A. The rotating speed signals of the fan after power amplification and filtration are output to a direct current air supply fan. The purpose of controlling the combusting work condition of a water heater and protecting air pressure is realized by following the rotating speed of the fan.

Owner:GUANGDONG HUAMEI JUNDA ELECTRIC APPLIANCES

Air distributor and ship air conditioning system

ActiveCN112520005ASuppress turbulenceSuppress eddy currentAuxillariesVessel ventillation/heating/coolingEngineeringMechanics

The invention belongs to the technical field of ship air conditioning systems, and discloses an air distributor and a ship air conditioning system. The air distributor comprises an air inlet mechanism, a pressure stabilizing box, an air outlet mechanism and a flow guide folded plate. The air inlet mechanism and the air outlet mechanism are fixed on the pressure stabilizing box; the flow guide folded plate comprises a first flow guide plate and a second flow guide plate; the first flow guide plate is fixed to the inner wall of the pressure stabilizing box, and an air inlet buffer cavity is formed in the air inlet side in the pressure stabilizing box. The second flow guide plate is fixed to the inner wall of the pressure stabilizing box, and a pressure stabilizing buffer cavity is formed inthe air outlet side in the pressure stabilizing box. The second flow guide plate is connected with the first flow guide plate to form a V-like flow guide cap; an inner cavity of the V-like flow guidecap is communicated with the air outlet mechanism, and the V-like flow guide cap is located above an air outlet of the air outlet mechanism; a flow stabilizing channel is reserved between the air inlet buffer cavity and the pressure stabilizing buffer cavity. According to the air distributor and the ship air conditioning system, noise can be greatly reduced.

Owner:WUCHANG SHIPBUILDING IND

Concrete station and method for dedusting by stages according to operation process

ActiveCN101352895BReduce in quantityCompact structureMixing operation plantTowerConstruction aggregate

The invention relates to a concrete mixing plant which can carry out staged dedusting in the working process and a method; the concrete mixing plant consists of a stirring mill, an aggregate temporary storage bin, a main tower composed of a powder metering device, a dust removing device and a control unit. The stirring mill is communicated with the dust removing device by a first dust transfer passage, the powder metering device is communicated with the aggregate temporary storage bin by a second dust transfer passage, the dust removing device is connected with the aggregate temporary storagebin and is communicated with the aggregate temporary storage bin by a third dust transfer passage, the third dust transfer passage is internally equipped with a ventilation door which can be opened or closed, the ventilation door can be manipulated by a door operation mechanism to shift between an open position and a closed position, and the door operation mechanism is arranged to be controlled by the control unit. The staged dedusting method is characterized in that: the dust removing device can carry out dedusting operation during the process of putting aggregate into the aggregate temporary storage bin by optionally closing or opening the ventilation door, while dedusting operation is stopped during the process of transferring the aggregate from the aggregate temporary storage bin intothe stirring mill.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

Multifunctional mosquito killing lamp

InactiveCN109526908ALarge openingSufficient air volumeInsect catchers and killersOxygen ionsEngineering

The invention discloses a multifunctional mosquito killing lamp. The multifunctional mosquito killing lamp includes a top cover, a solar cell panel, an ultraviolet lamp tube, a wind net, an air purification negative ion device, a mosquito cage, a wind channel, a turbine fan and a fan. The solar cell panel is located on the top cover. The ultraviolet lamp tube is located under the top cover. The mosquito cage connects the wind net and the base. The air purification negative ion device is located on the upper part of the inside of the mosquito cage. The wind channel is of a funnel shape and located on the lower part of the inside of the mosquito cage. The turbine fan is located in the lower half funnel of the wind channel. The base bears the whole structure. The multifunctional mosquito killing lamp of the invention utilizes a unique light wave of ultraviolet to attract mosquitoes, and catches the mosquitoes through the cooperation of the wind net, wind channel and turbine fan. The solarcell panel provides energy, which is saving and environmentally friendly. The air purification negative ion device releases negative oxygen ions which can kill the mosquitoes and purify air.

Owner:JIANGSU HUAXIA INTPROP SERVICE CO LTD

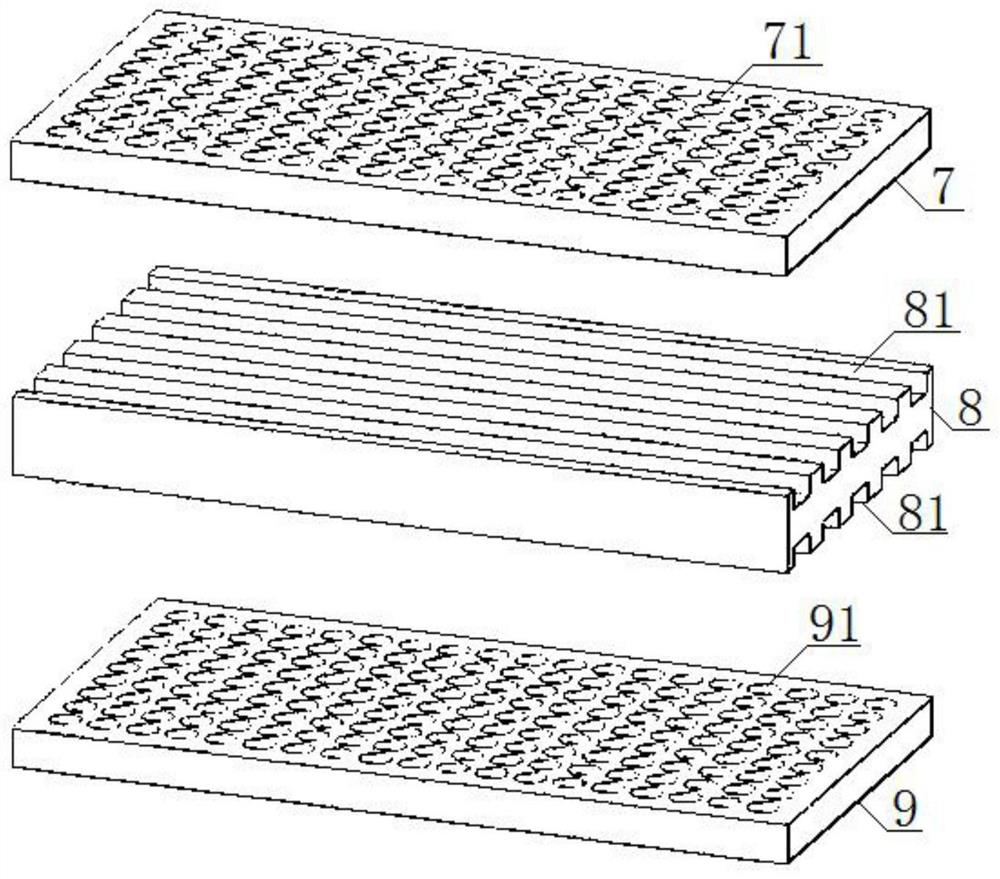

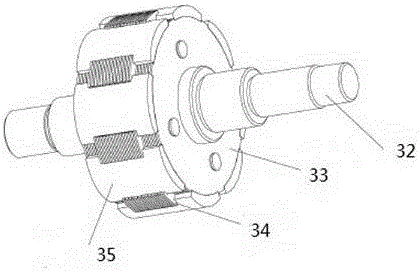

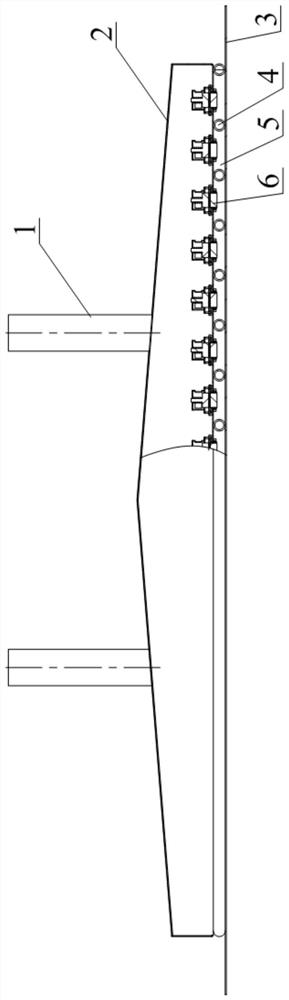

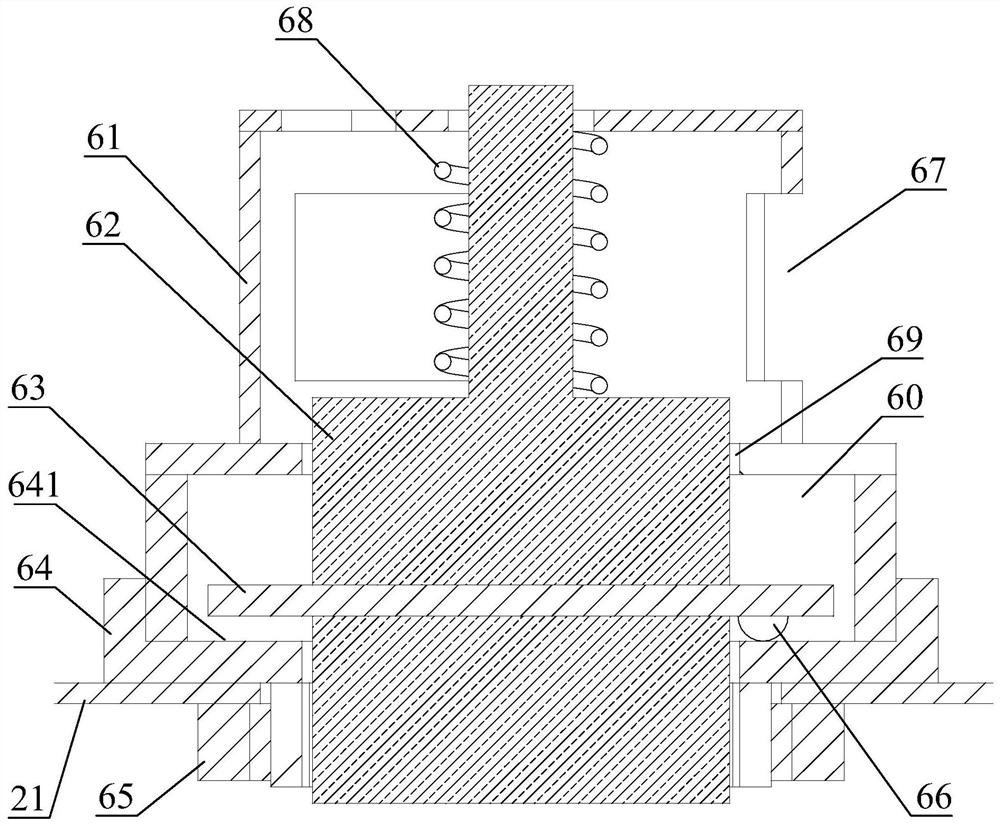

A high-efficiency thread suction machine that prevents thread from clogging the filter plate

ActiveCN104801515BAvoid accumulationGuaranteed wind pressureMagnetic circuit rotating partsMagnetic circuit stationary partsInlet channelEngineering

Owner:桐乡市立明喷织股份有限公司

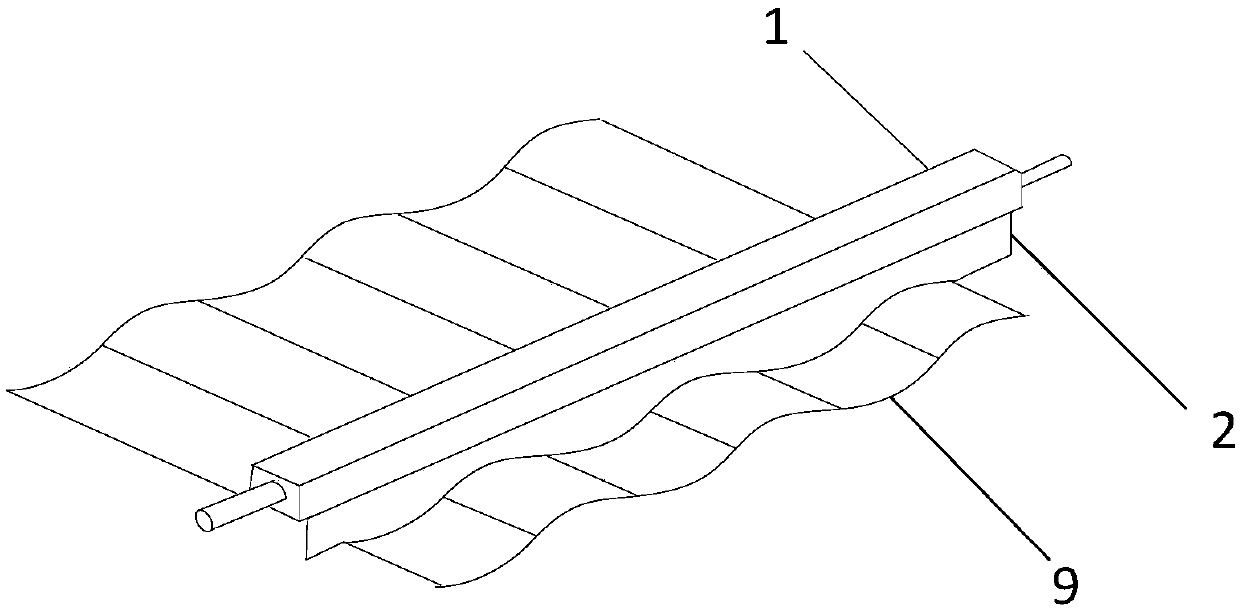

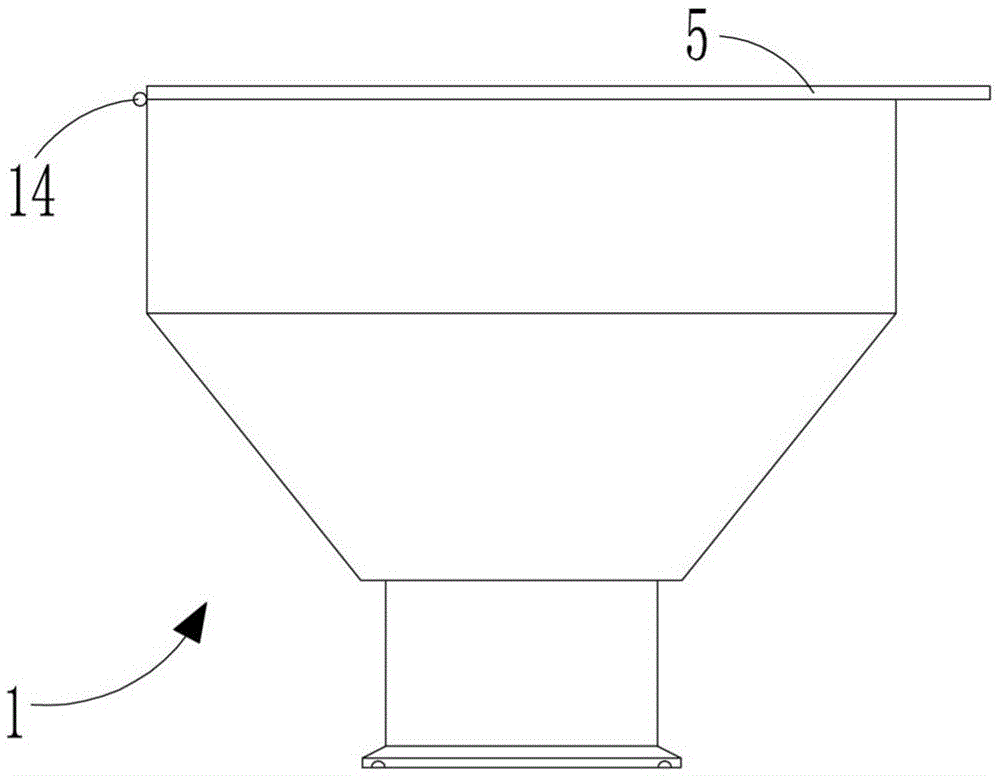

Air Dryer for Plastic Straps

InactiveCN103557681BGuaranteed wind pressureSimple designDrying machines with progressive movementsDrying solid materialsWater dischargeWater flow

The invention discloses an air-drying device for plastic braces, which comprises a conveying unit, an air-drying unit, and a gas-liquid separation unit. The air-drying unit includes a water receiving tray and a fan connected to the bottom of the water receiving tray through an air pipe. The conveying unit includes a set The two sets of conveying rollers on the upper end of the water receiving tray, the cover plate located above the water receiving tray, the plastic stays are moved and tensioned between the two sets of conveying rollers and the cover plate, and the gas-liquid separation unit includes a A separation box with a separation chamber inside. The lower part of the separation box has a drain port and the upper part has an exhaust port. A gas-liquid separation channel is formed between the air outlet of the fan and the exhaust port. The cover plate is hingedly installed on the upper part of the water tray to ensure the wind pressure of the air inlet when the fan is working. The fan sucks away the moisture on the plastic braces in real time, and the air flow with water enters the gas-liquid separation unit from the air outlet. After separation, the gas flows from the exhaust port. Drain, the water is discharged from the drain port, the structure is simple, compact, simple and beautiful, the work is reliable, and the work efficiency is effectively improved.

Owner:苏州金纬片板膜智能装备有限公司

Differential kiln capable of automatically cooling bearing to realize dust removal

The invention discloses a differential kiln capable of automatically cooling a bearing to realize dust removal. The differential kiln comprises a kiln body, a loop tower, a loop tower bearing and a high-pressure blower communicated with the kiln body, wherein the loop tower bearing comprises balls, a lower ball seat fixedly arranged and an annular upper ball seat arranged on the lower ball seat; a ball groove is arranged between the upper ball seat and the lower ball seat; the upper ball seat or lower ball seat is provided with an air inlet communicated with the ball groove; the air inlet is communicated with the high-pressure blower; and the upper ball seat is provided with an air outlet communicating the ball groove and the upper surface of the upper ball seat. In use, high-pressure air generated by the high-pressure blower is blown into the ball groove through the air inlet and then discharged into the kiln for calcining through air outlet, and the process can effectively cool the balls and the ball groove and remove dust out of the ball groove; and meanwhile, a certain air pressure is kept in the ball groove, thereby effectively preventing external dust from moving in the ball groove. Thus, in a working environment of a low rotation speed, the bearing can not seriously damaged without use of any lubricating oil, thereby ensuring that the bearing is maintenance-free.

Owner:CHONGQING YUXI IND GRP

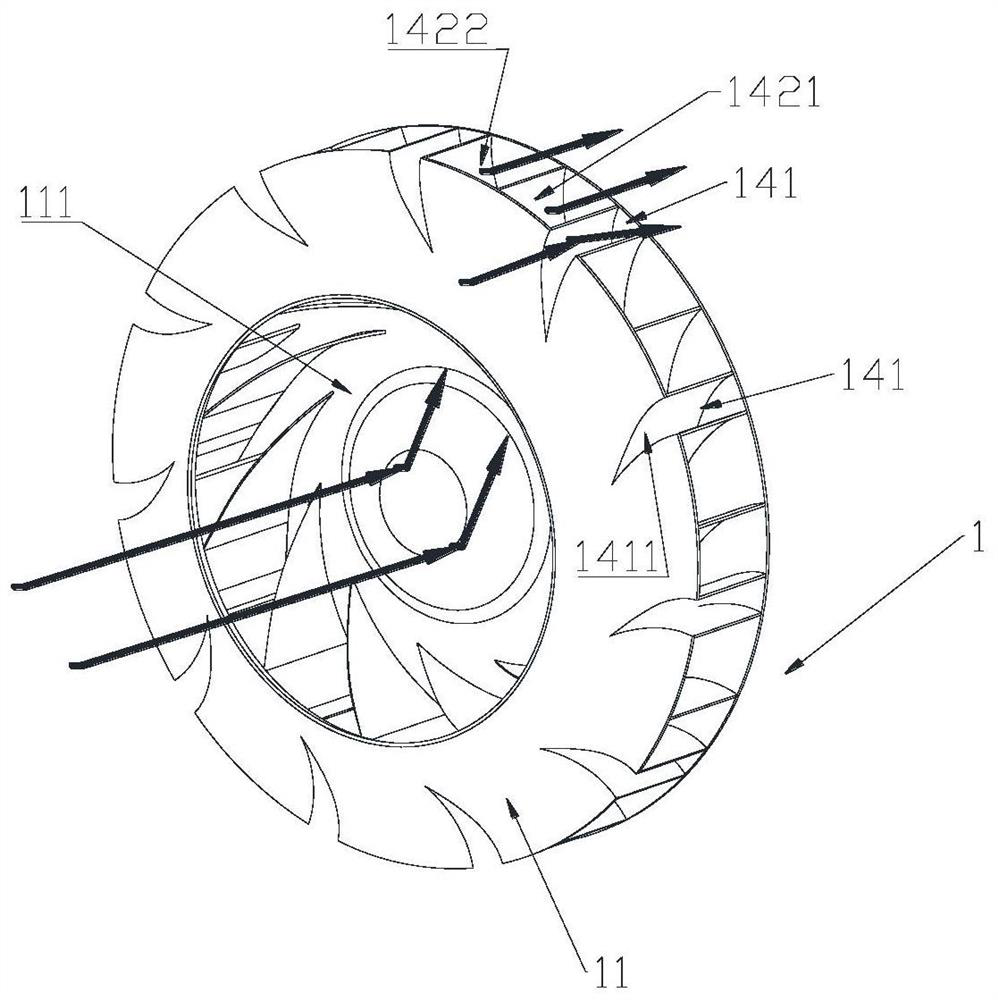

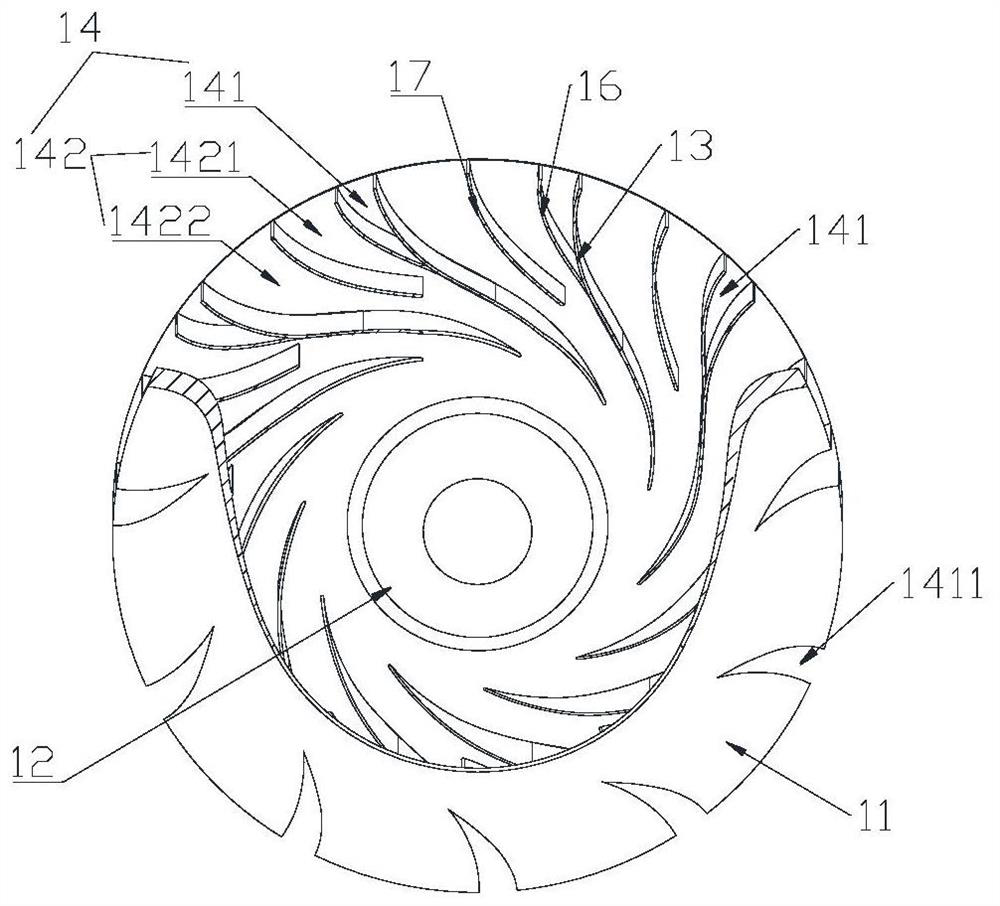

Centrifugal fan and range hood

PendingCN113757166AImprove ventilationIncrease air volumeDomestic stoves or rangesPump componentsImpellerFan blade

The invention discloses a centrifugal fan and a range hood. The centrifugal fan comprises an impeller and a plurality of main fan blades; the impeller comprises a front disc, a main air inlet and a bottom disc; the main air inlet is formed in the center of the front disc and used for feeding air into the impeller; the bottom disc is arranged opposite to the front disc; the main fan blades extend from the center of the impeller to the periphery and are sequentially distributed between the front disc and the bottom disc in the circumferential direction, an air outlet channel is formed between every two adjacent main fan blades, and the air outlet channels are matched with the main air inlet to form a main air channel; and at least one air outlet channel is internally provided with an auxiliary air channel, the front disc is correspondingly provided with an auxiliary air inlet used for feeding air into the auxiliary air channel, and the auxiliary air inlet is formed in the position close to the periphery of the front disc relative to the main air inlet. According to the centrifugal fan, ventilation can be achieved through the main air channels of the impeller and can also be achieved through the auxiliary air channels, and the ventilation quantity is increased; and in addition, the auxiliary air channels are arranged in the corresponding air outlet channels, so that the pressure difference in the air outlet channels can be reduced, the vortex effect is reduced, and then noise is reduced.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

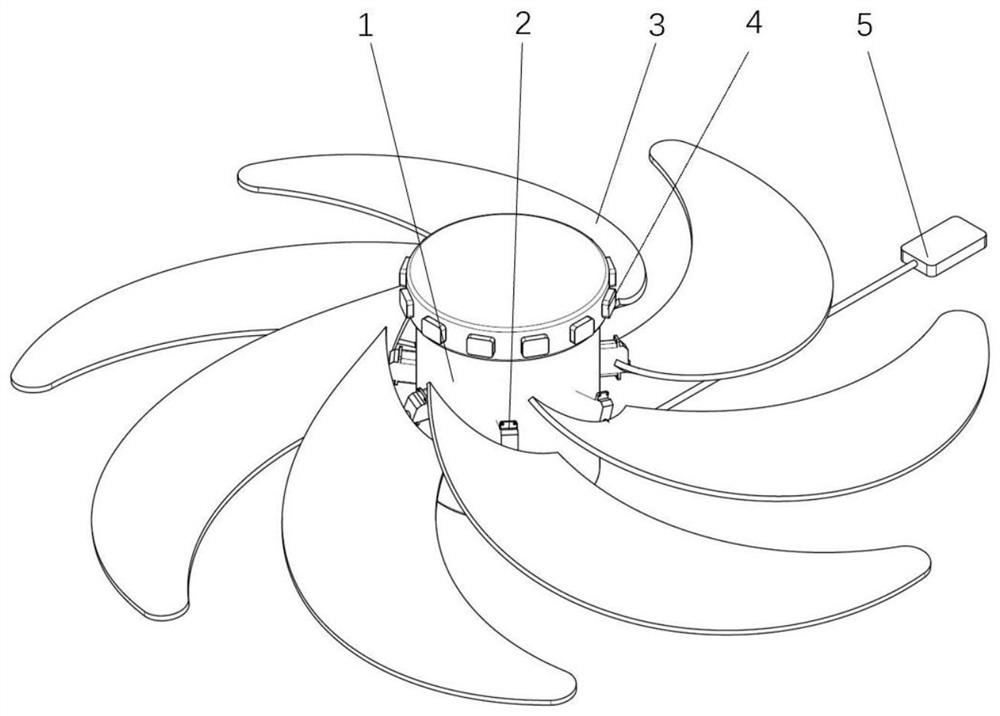

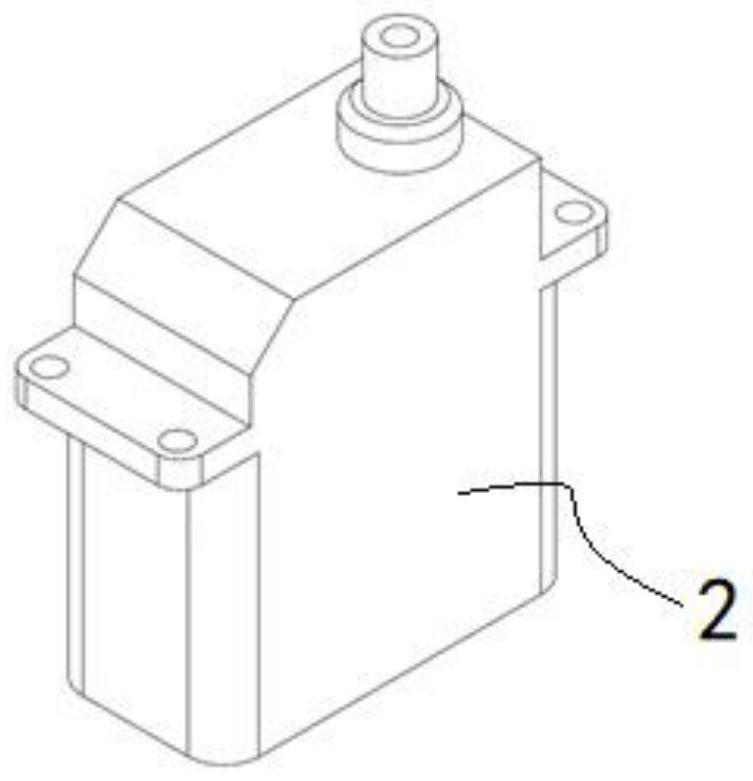

A self-adjusting bionic fan with variable angle

InactiveCN112555193BIncrease and stabilize air volumeImprove passabilityPump componentsPump controlAgricultural engineeringFan blade

The invention relates to the field of agricultural machinery, in particular to a self-regulating bionic fan with a variable angle, which consists of a center mounting carrier, a steering gear, bionic fan blades, a gas flow sensor and an embedded development board; the bionic Between the two points A and B on the upper half of the fan blade is the outer edge curve of the fan blade. The outer edge curve is formed by connecting a plurality of convex outer edge convex hulls (simulating the outer edge curve of the humpback whale fin) ; The inner edge curve of the fan blade is between the two points of the lower half of the bionic fan blade A', B', and the inner edge curve is formed by a plurality of (simulated humpback whale fin outer edge curves) concave inner curves. The bionic fan of the invention can imitate the swing of the fins of the whale when it is swimming, increase the air flow of the fan, and stabilize the air flow at the same time. It is suitable for the operation of the pneumatic seed meter in any environment .

Owner:JILIN UNIV

Suction cup device and artificial board production equipment

ActiveCN113213153AGuaranteed wind pressureImprove adsorption capacityConveyorsEqualizing valvesStructural engineeringIndustrial engineering

The invention discloses a suction cup device and artificial board production equipment. The suction cup device comprises a suspended hood, wherein a plurality of suction openings are formed in the air suction face of the suspended hood; a plurality of sealing rings surrounding the suction openings in a one-to-one correspondence mode are arranged at the outer side of the suspended hood; at least one suction opening is provided with a self-locking valve; the self-locking valve comprises a valve shell and a valve core; the valve shell is provided with a valve channel communicated with the suction opening in a penetrating mode; the valve core is movably connected to the valve shell through a reset mechanism; the reset mechanism is used for driving the valve core to communicate the valve channel and the suction opening; and the valve core can partially block the valve channel and / or the suction opening in the air suction direction under the air suction effect. According to the scheme, leaking stoppage measures are taken for damaged plates, air pressure is effectively guaranteed, the adsorption effect is greatly improved, and the equipment weight and energy consumption are reduced.

Owner:扬州快乐机械有限公司 +2

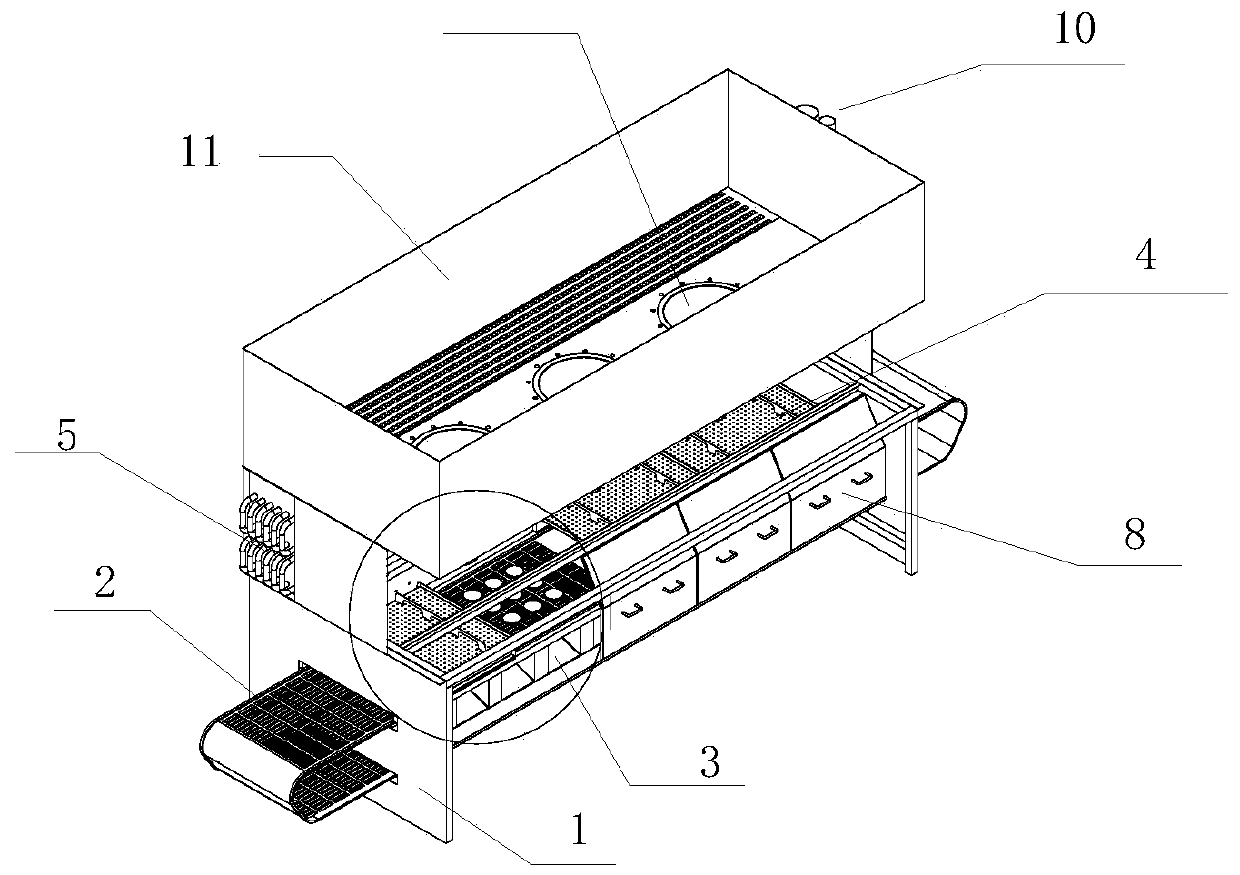

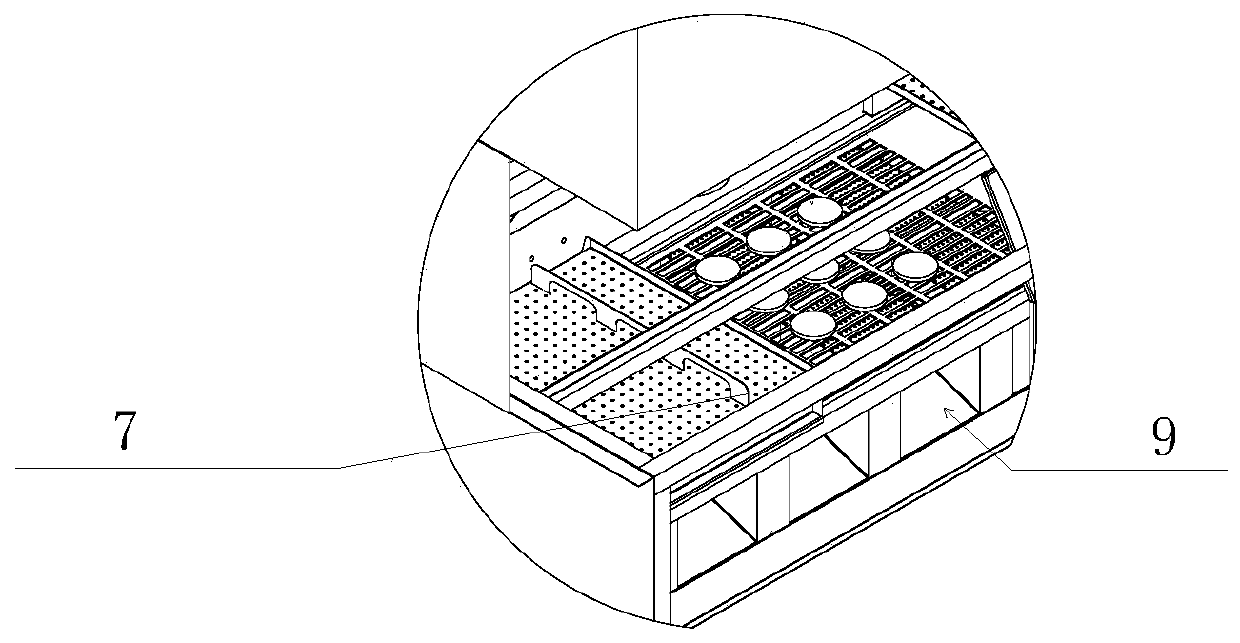

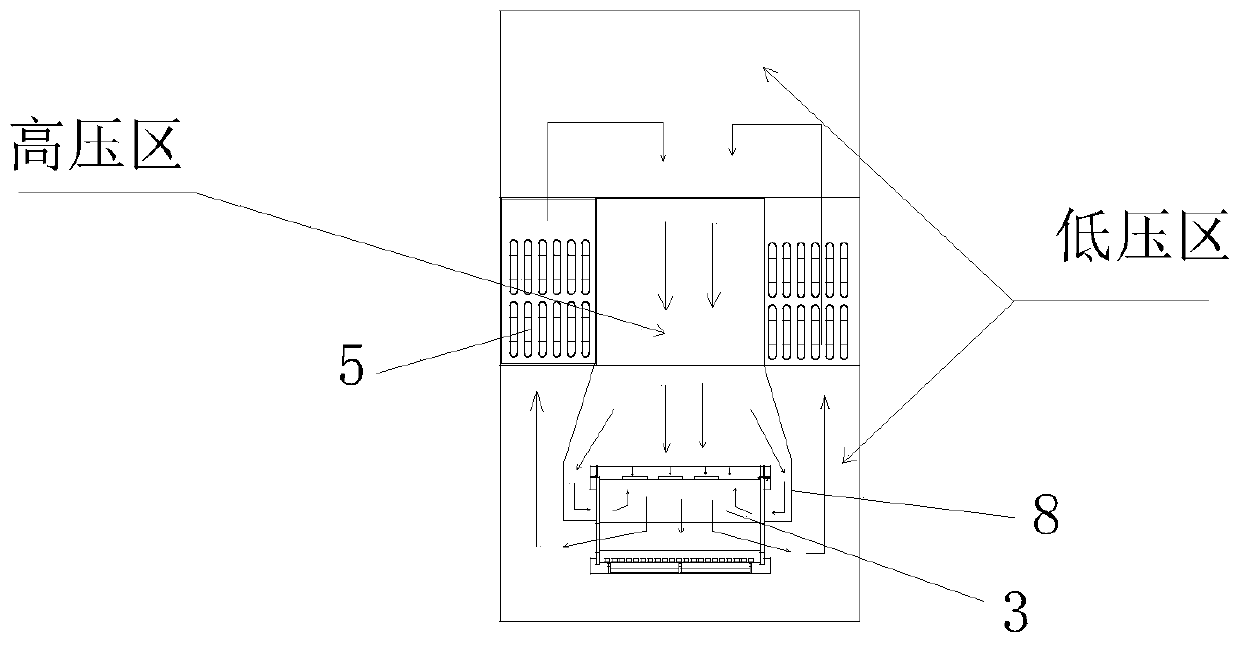

Impact type rapid refrigerating machine

PendingCN110411120ACompact structureSmall footprintLighting and heating apparatusStationary refrigeration devicesFlueEvaporator

The invention discloses an impact type rapid refrigerating machine. The refrigerating machine comprises a machine frame and a shell body, wherein a conveyor belt is arranged in the position, on the upper part of the machine frame, of the shell body; an upper air flue mesh plate is arranged right above the conveyor belt, and the upper air flue mesh plate is arranged below an evaporator and a fan; an upper air flue is arranged above the conveyor belt; a lower air flue is arranged below the conveyor belt; the evaporator is arranged on the side surface of the upper air flue above the conveyor beltand connected with the shell body; one end of the evaporator is connected with the fan and the upper air flue through an air sleeve to form a circulating air flue, and the other end of the evaporatoris connected with a refrigerant pipe through a pipeline; the fan is arranged in the upper air flue above the conveyor belt, and the evaporator and the fan are located at the same height; and the sideface of the conveyor belt is provided with a high-low pressure partition plate, and the high-low pressure partition plate extends from the bottom of the evaporator to the lower air flue below the edge of the conveyor belt. According to the refrigerating machine, the circulation of cold air can be ensured, it is guaranteed that each to-be-frozen product can be fully and uniformly frozen, and the refrigerating is rapid and efficient. Meanwhile, the refrigerating machine is small in occupied area and low in production cost compared with a traditional large-scale refrigerating machine.

Owner:杰欧(江苏)冷链装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com