Electric spray gun

An electric and spray gun technology, used in spray devices, liquid spray devices, etc., can solve problems such as damage, shortened service life, burns, etc., and achieve the effect of ensuring spraying quality, reducing surface temperature, and extending service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

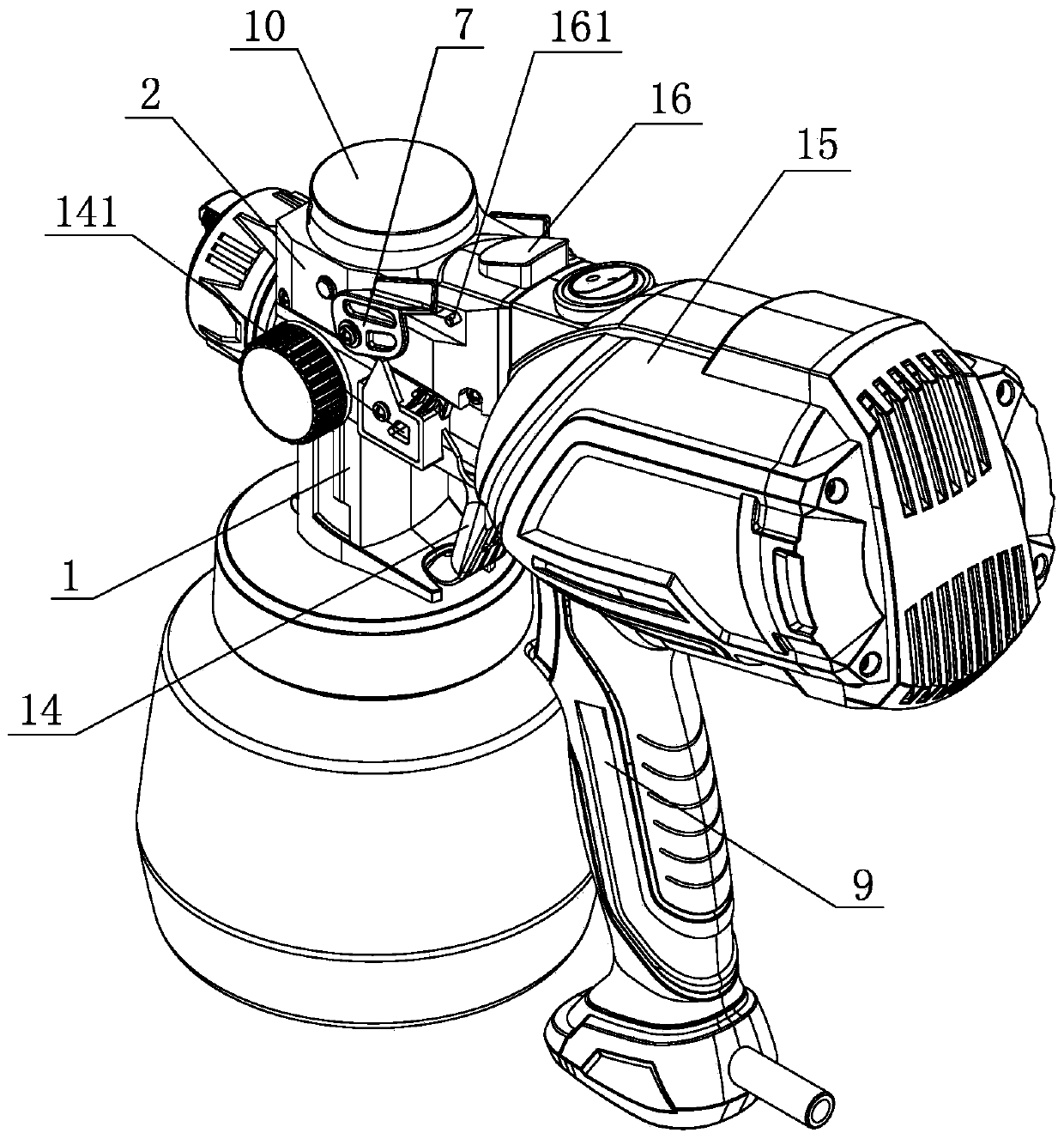

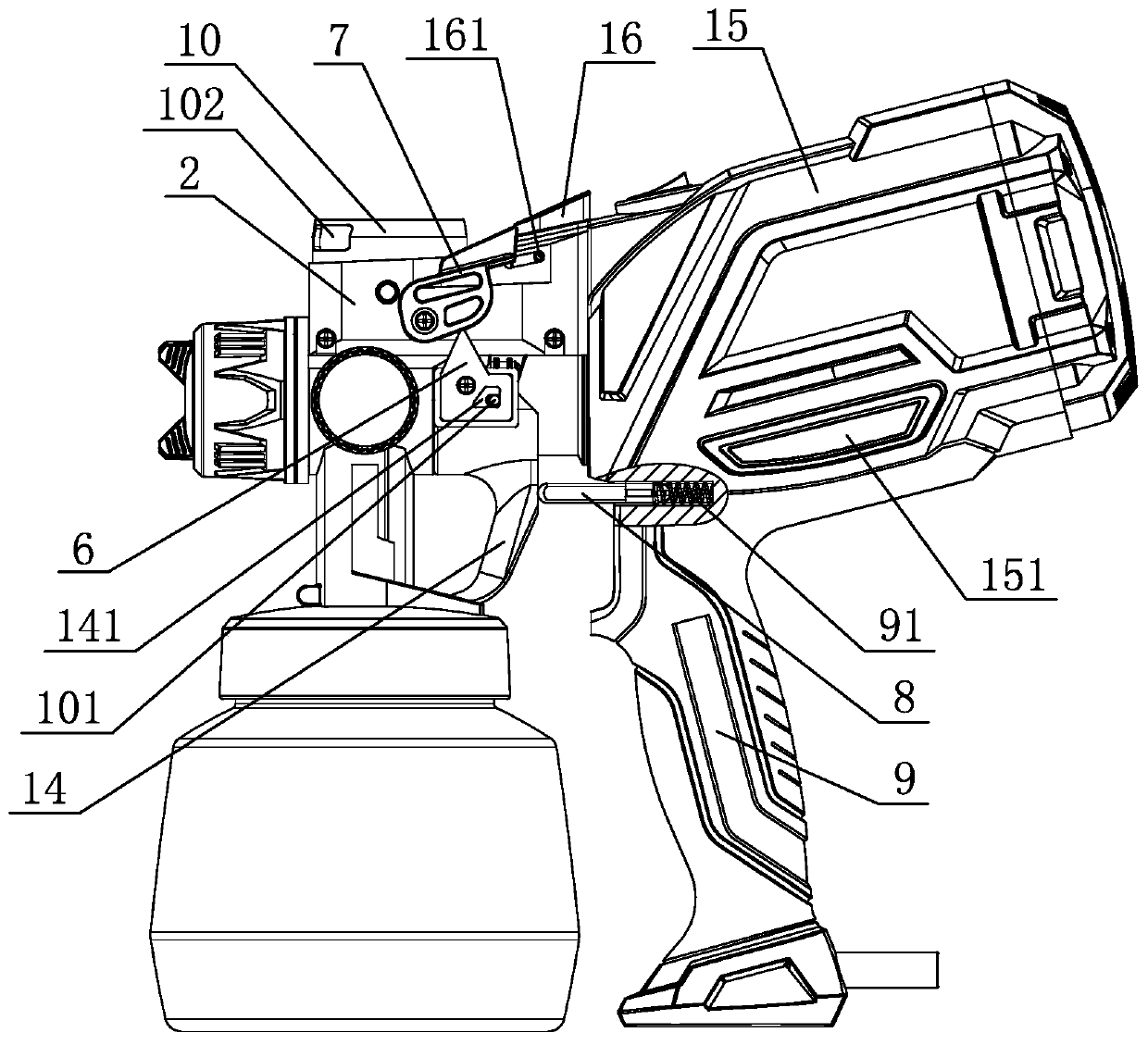

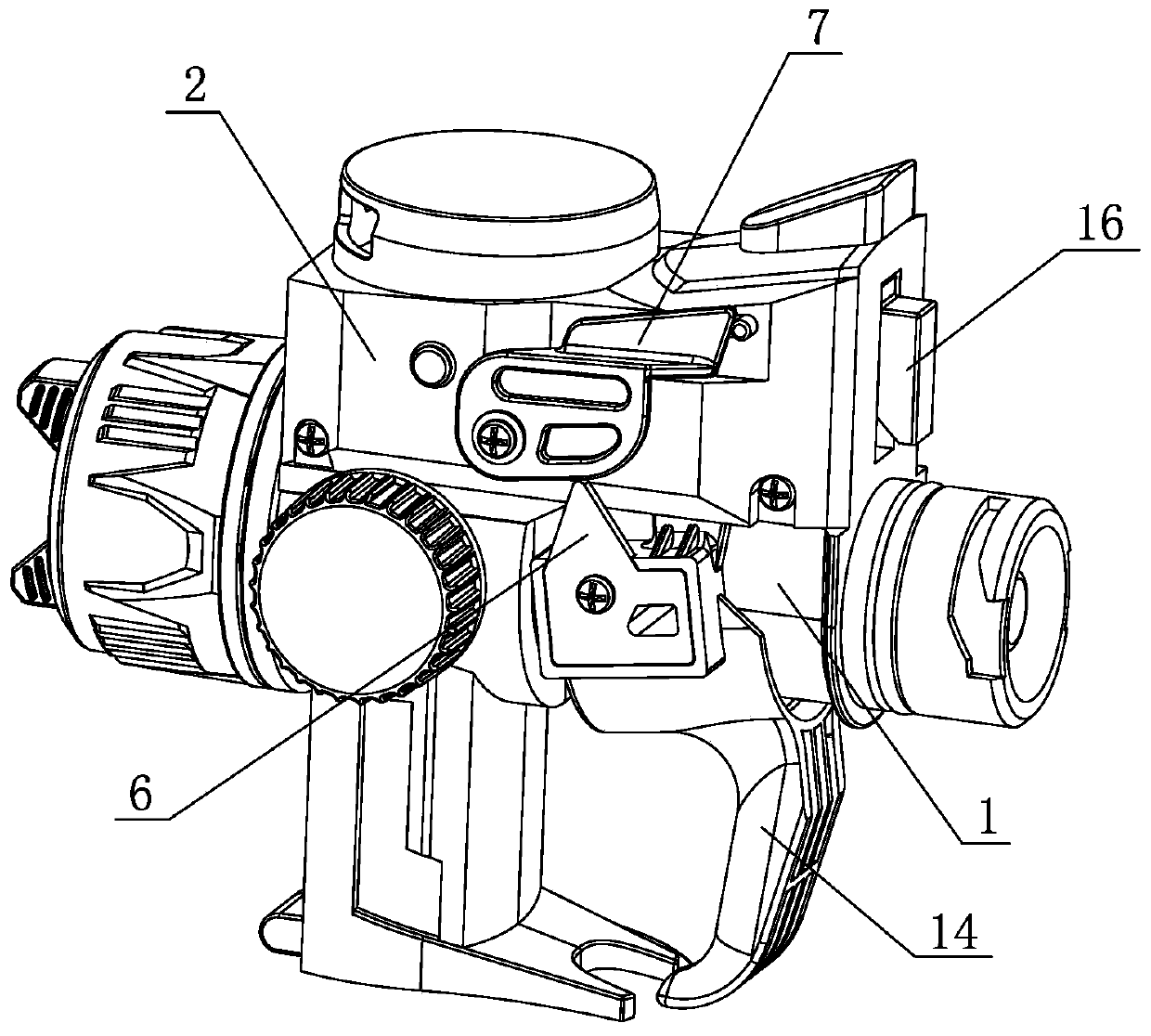

[0028] Embodiment 1: As shown in the figure, in this embodiment, the handle 9 of the electric spray gun and the rear casing 15 for installing the motor and the fan are fixed or integrally arranged, and the rear casing 15 is connected with the front gun body 1, specifically for:

[0029]An electric spray gun, comprising a front gun body 1 for installing a valve stem 100, the front gun body 1 is provided with an auxiliary air outlet 11, the auxiliary air outlet 11 is independent from the air outlet 12 at the front end of the front gun body 1, and the auxiliary air outlet 11 communicates with the air passage 13 in the front gun body 1, and the auxiliary air outlet 11 is provided with an air outlet opening and closing control mechanism, which includes the first air cover 2, the rotating plate 3, the linkage plate 4 and the first spring 5. The first air cover 2 is fixed on the front gun body 1 and covers the auxiliary air outlet 11. The first air cover 2 is provided with a first ai...

Embodiment 2

[0032] Embodiment 2: As shown in the figure, an electric spray gun includes a front gun body 1 for installing a valve stem 100. An auxiliary air outlet 11 is arranged on the front gun body 1. The auxiliary air outlet 11 is connected to the front end of the front gun body 1. The air outlets 12 are independent of each other, the auxiliary air outlet 11 is connected with the air passage 13 in the front gun body 1, the auxiliary air outlet 11 is provided with an air outlet opening and closing control mechanism, and the air outlet opening and closing control mechanism includes a second air cover 18 and an air cap 19 , the second air cover 18 is fixed on the front gun body 1 and covers the auxiliary air outlet 11, the second air cover 18 is integrally provided with a mount 181, the mount 181 is provided with a third air outlet 182, the third air outlet 182 communicates with the auxiliary air outlet 11, and the air cap 19 is sleeved on the mounting base 181 and rotates with the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com