Automatic following control circuit for fan

An automatic tracking and control circuit technology, applied in the direction of pump control, machine/engine, mechanical equipment, etc., can solve the problem of difficult wind pressure protection for strong drum gas water heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

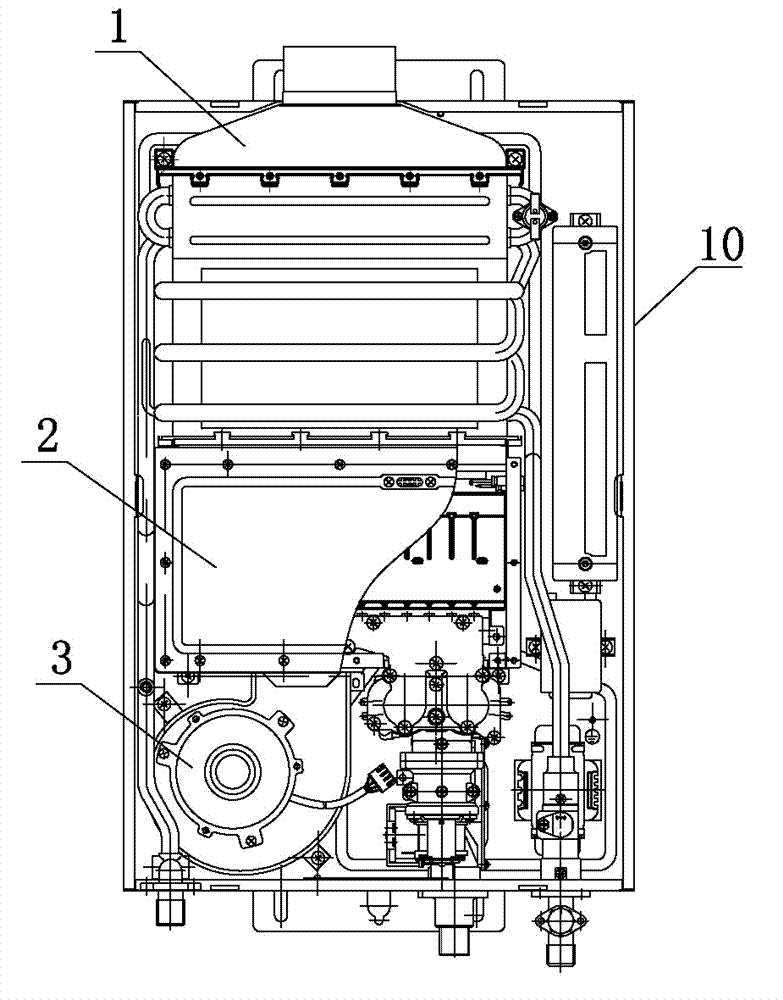

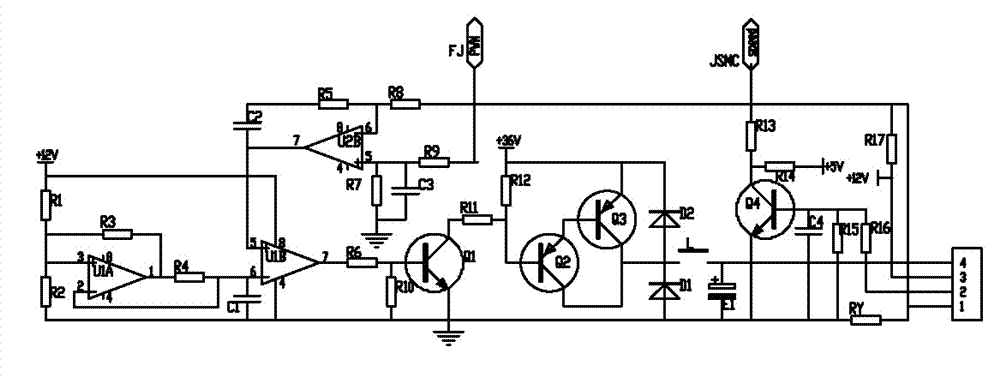

[0011] like figure 1 and figure 2 As shown, the present invention provides a fan automatic tracking control circuit, which is mainly suitable for the strong drum type gas water heater 10, and utilizes the mechanism that the flow rate of the strong blower 3 is proportional to the speed; the wind pressure is proportional to the square of the speed. The basic circuit is composed of single-chip microcomputer and PWM drive circuit, and the current feedback circuit is used to stabilize the working state of the fan and automatically track the change of wind pressure.

[0012] Please refer to figure 1 shown. It is the structural diagram of the strong drum type gas water heater. Among them, it can be seen that when the strong drum type gas water heater 10 is working, the gas is burned in a sealed burner 2 isolated from the outside world, and the air required for gas combustion is completely supplied by the strong blower 3, and the air volume is strictly proportional to the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com