Dust recovery system of electrolyte manual cleaning workshop section

A technology for cleaning section and dust recovery, applied in the direction of removing smoke and dust, cleaning methods and utensils, separation of dispersed particles, etc., it can solve the problem that the slot type dust hood is difficult to achieve dust collection effect, the operator's physical and mental health hazards, and the lack of dust removal. System setting conditions and other issues, to achieve a good application prospect and achieve the effect of effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

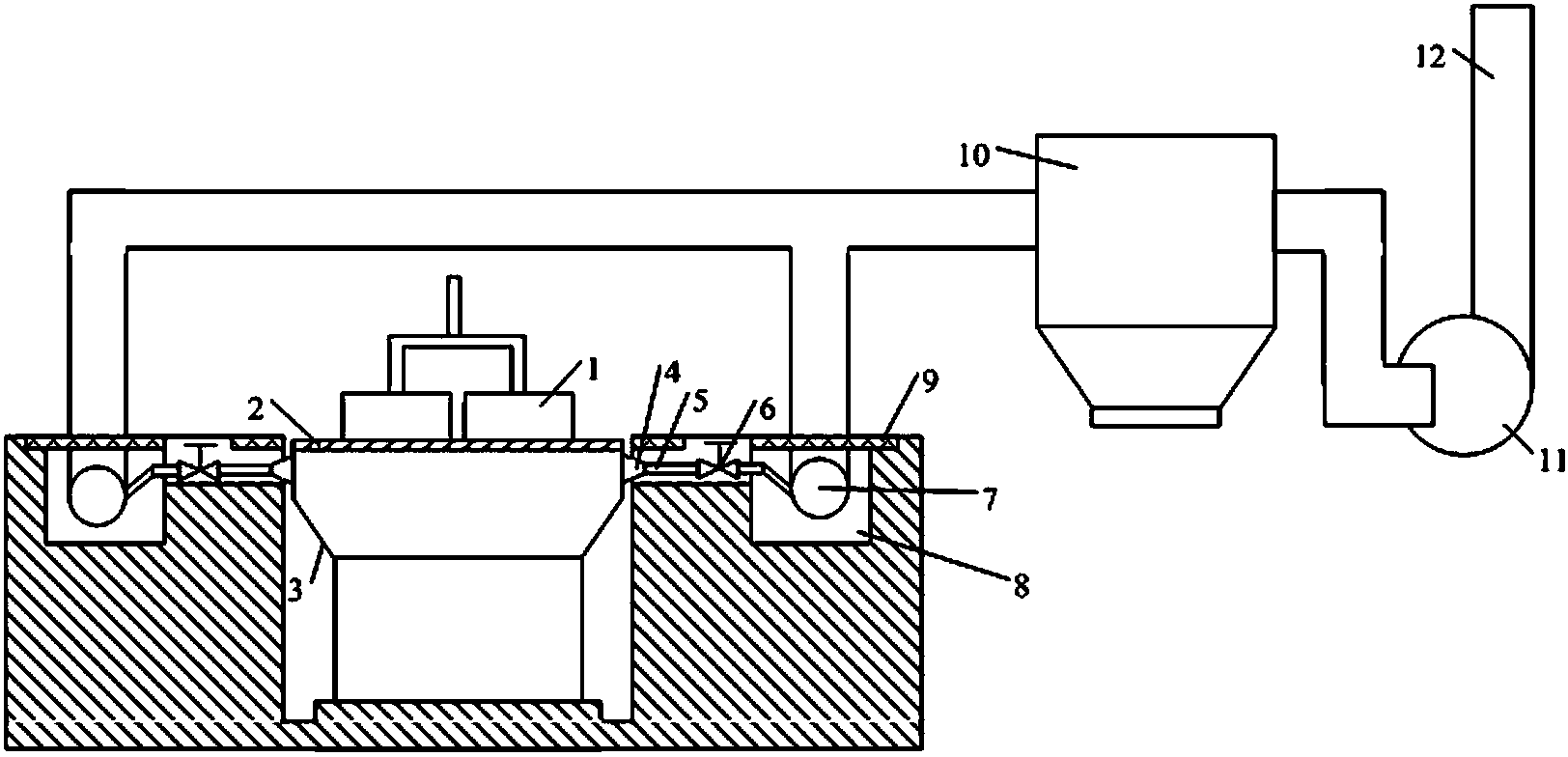

[0024] The structure of the dust recovery system in the electrolyte manual cleaning section is as follows: figure 1 As shown, it includes a feeding hopper 3, a bag filter 10, a centrifugal fan 11, a dust removal duct 7 and an exhaust hood 4;

[0025] An independent discharge hopper 3 is installed under the discharge grille 2 of each station in the electrolyte manual cleaning section, and openings are provided on opposite sides of the upper part of each discharge hopper 3, and the openings are respectively connected with an exhaust hood 4 , the exhaust hood 4 on the same side of each feeding hopper 3 is connected with a dust removal duct 7, and the two dust removal ducts 7 are connected with the air inlet of the bag filter 10 at the same time, and the air outlet of the bag filter 10 is It is connected with the inlet of the centrifugal fan 11; the outlet of the centrifugal fan 11 is connected with an exhaust pipe 12;

[0026] The exhaust hood 4 communicates with the dust remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com