Air Dryer for Plastic Straps

An air-drying device and strip-drawing technology, applied in drying, dryers, progressive dryers, etc., can solve problems affecting work efficiency, wind splashing everywhere, loud noise, etc., to achieve reliable work, improve work efficiency, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

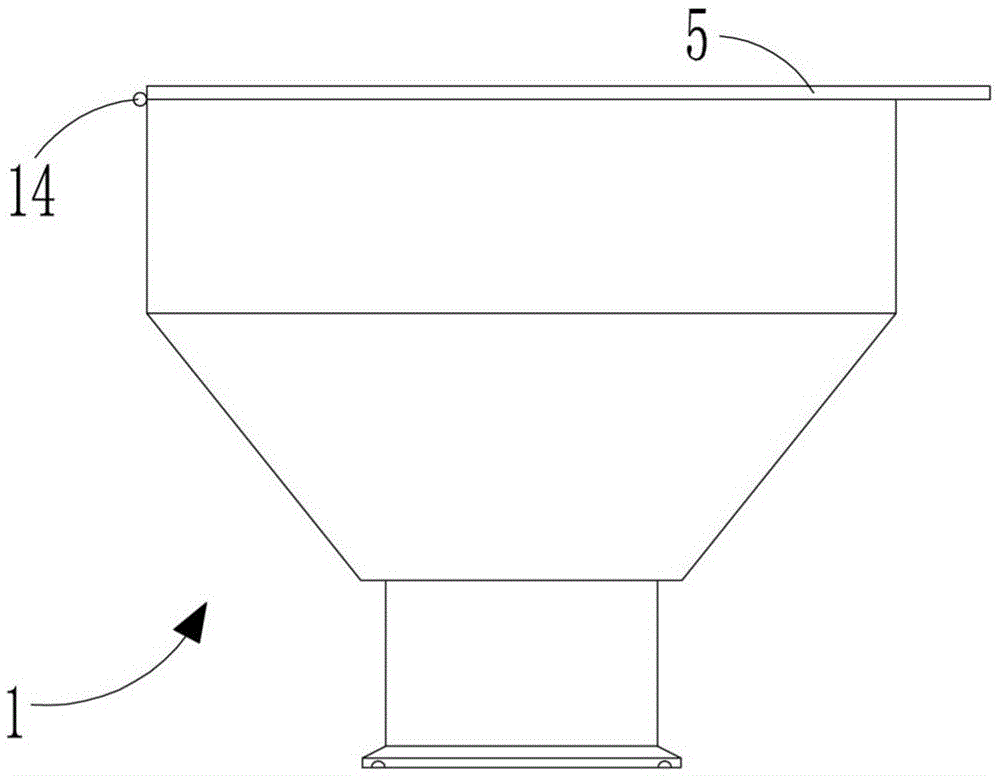

[0023] Instructions attached Figure 5 The solid arrows in the figure indicate the running direction of water-laden airflow, and the hollow arrows indicate the running direction of water-free airflow.

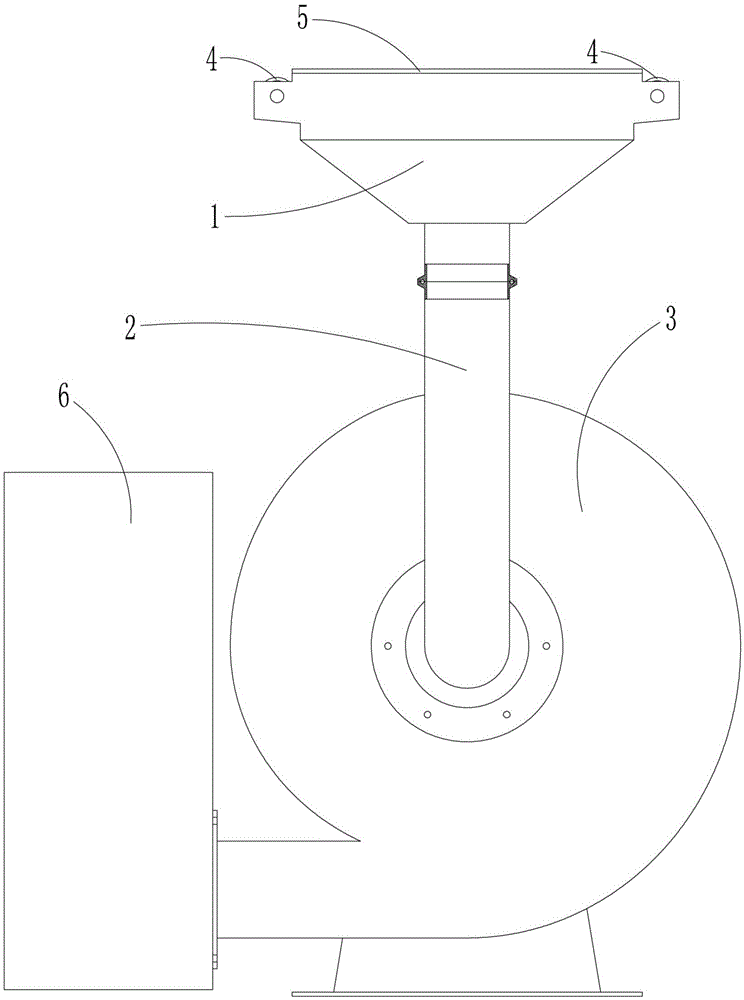

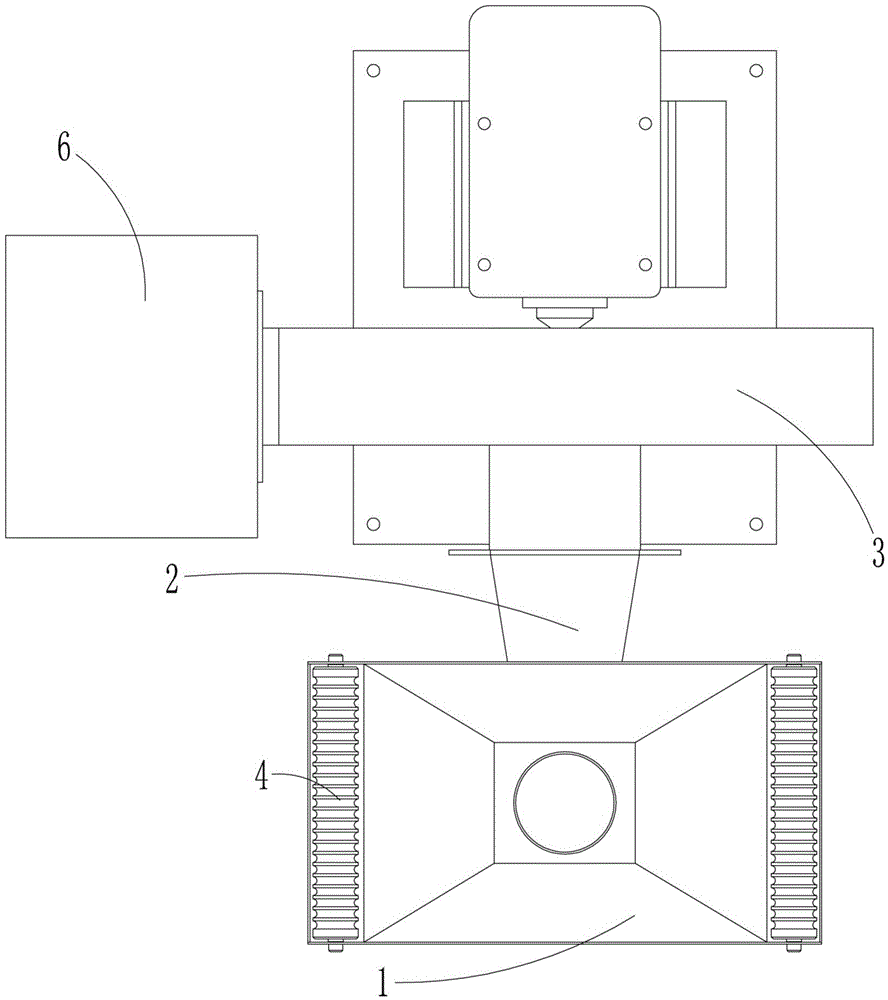

[0024] as attached figure 1 to attach Figure 5 As shown, an air-drying device for plastic braces includes a conveying unit for conveying plastic braces, an air-drying unit, and a gas-liquid separation unit. The blower fan 3 at the bottom of the water tray 1, the conveying unit includes two sets of conveying rollers 4 arranged on opposite sides of the upper end of the water tray 1, the cover plate 5 positioned above the water tray 1, and the plastic braces can be moved to stretch Immediately between the two groups of conveying rollers 4 and the cover plate 5, the gas-liquid separation unit includes a separation box with a separation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com