A high-efficiency thread suction machine that prevents thread from clogging the filter plate

A thread suction machine and filter plate technology, which is applied in the field of garment processing, can solve the problems of low adsorption efficiency and poor adsorption effect, and achieve the effects of improving efficiency, preventing accumulation, and reducing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

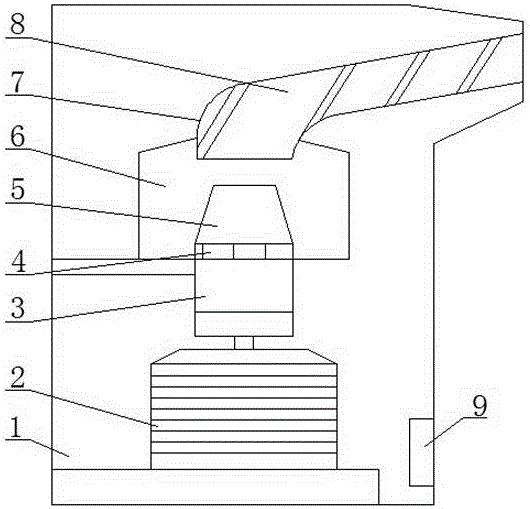

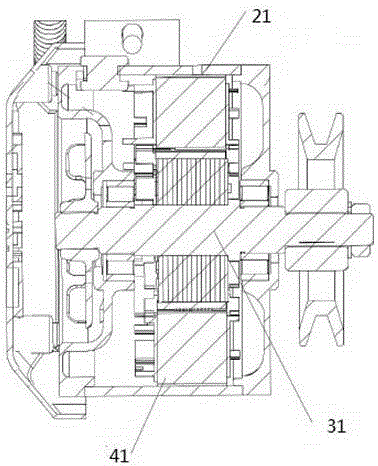

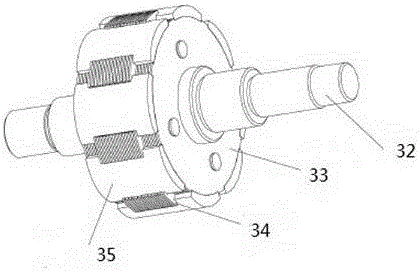

[0031] The high-efficiency thread-end suction machine for preventing thread ends from clogging the filter plate in this embodiment includes a casing, and a centrifugal fan driven by a driving motor is arranged in the casing, and a first filter plate is arranged on the upper end of the centrifugal fan, and the second filter plate is arranged on the upper end of the centrifugal fan. The casing on the upper side of a filter plate is provided with an air inlet duct, the lower side of the cabinet is provided with an air outlet, the periphery of the centrifugal fan is provided with a first air inlet passage, and the upper end of the first air inlet passage contacts The first filter plate, the top of the first filter plate is provided with a second air inlet channel with a small upper end and a large lower end, the lower end of the second air inlet channel corresponds to the first air inlet channel, and the second air inlet channel The upper end of the air inlet is provided with an ai...

Embodiment 2

[0033] The high-efficiency thread-end suction machine for preventing thread ends from clogging the filter plate in this embodiment includes a casing, and a centrifugal fan driven by a driving motor is arranged in the casing, and a first filter plate is arranged on the upper end of the centrifugal fan, and the second filter plate is arranged on the upper end of the centrifugal fan. The casing on the upper side of a filter plate is provided with an air inlet duct, the lower side of the cabinet is provided with an air outlet, the periphery of the centrifugal fan is provided with a first air inlet passage, and the upper end of the first air inlet passage contacts The first filter plate, the top of the first filter plate is provided with a second air inlet channel with a small upper end and a large lower end, the lower end of the second air inlet channel corresponds to the first air inlet channel, and the second air inlet channel The upper end of the air inlet is provided with an ai...

Embodiment 3

[0035] The high-efficiency thread-end suction machine for preventing thread ends from clogging the filter plate in this embodiment includes a casing, and a centrifugal fan driven by a driving motor is arranged in the casing, and a first filter plate is arranged on the upper end of the centrifugal fan, and the second filter plate is arranged on the upper end of the centrifugal fan. The casing on the upper side of a filter plate is provided with an air inlet duct, the lower side of the cabinet is provided with an air outlet, the periphery of the centrifugal fan is provided with a first air inlet passage, and the upper end of the first air inlet passage contacts The first filter plate, the top of the first filter plate is provided with a second air inlet channel with a small upper end and a large lower end, the lower end of the second air inlet channel corresponds to the first air inlet channel, and the second air inlet channel The upper end of the air inlet is provided with an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com