Apparatus for drying mirror silver ink and technique thereof

A technology of drying equipment and mirror silver, which is applied to the device for coating liquid on the surface, the pretreatment of the surface, the post-processing of printing, etc., can solve the problems of poor controllability, low efficiency, and difficult to control the drying time of ink, etc. Achieve the effect of ensuring uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

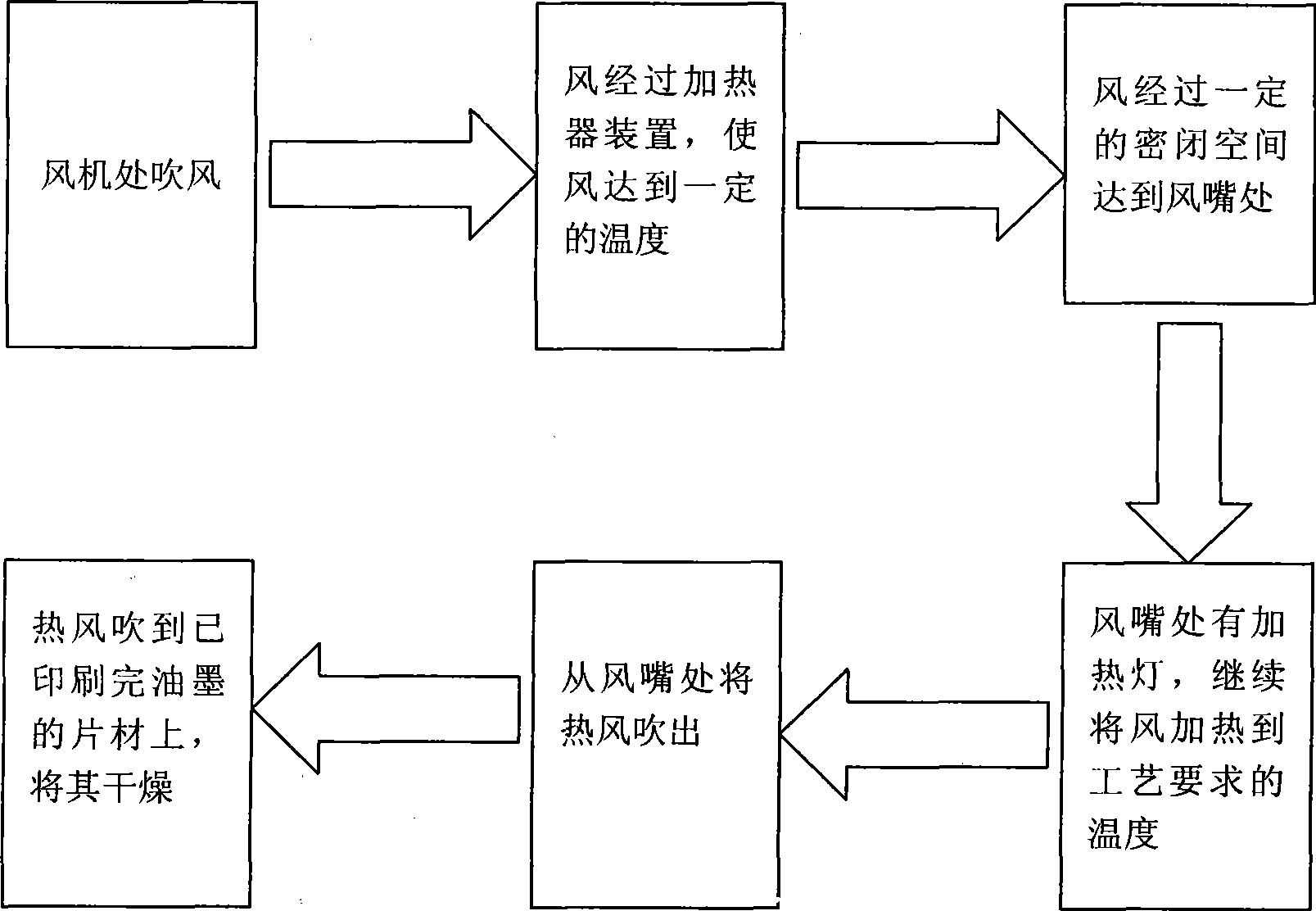

[0023] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

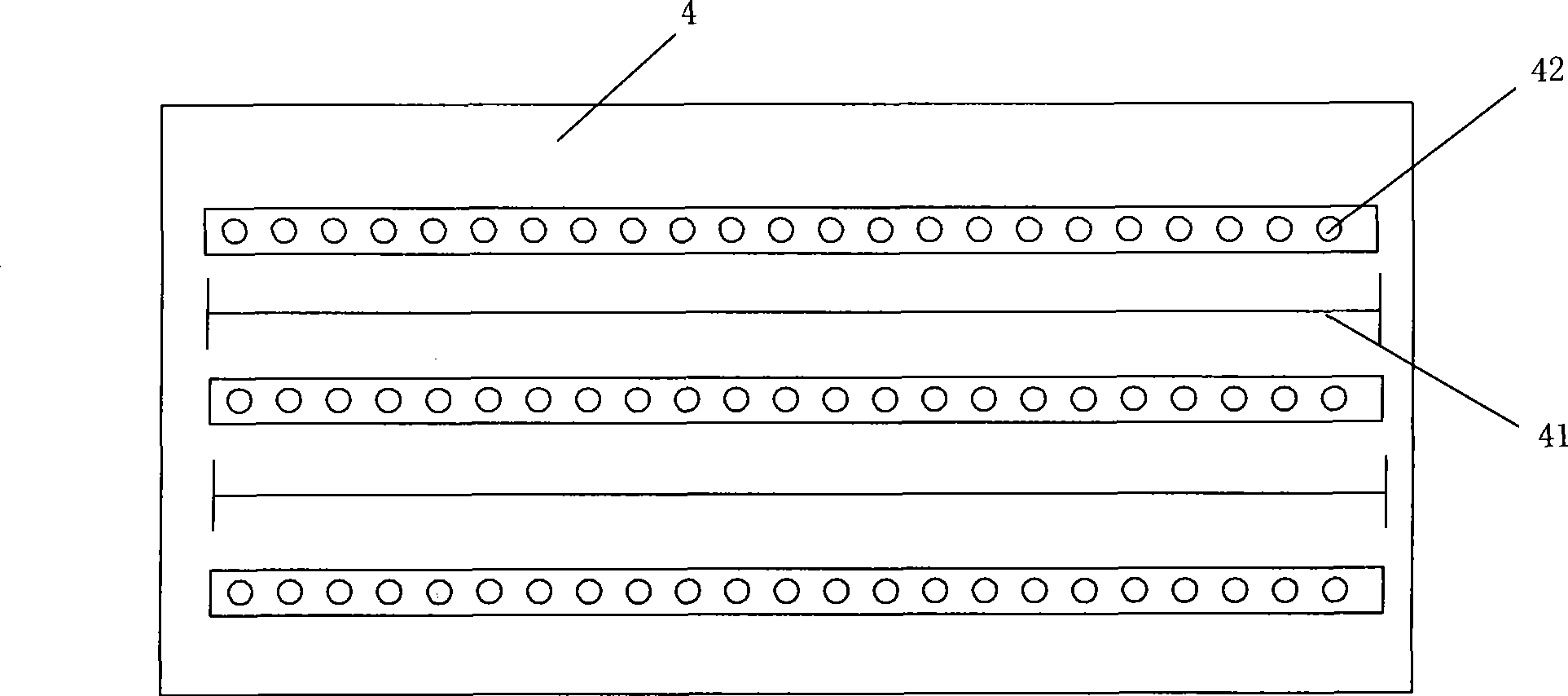

[0024] Such as Figures 1 to 4 As shown, the special drying equipment is provided with three air ducts, and each air duct has an air inlet, and heater 1, heater 2, and heater 3 are respectively installed in the air ducts at the fan air inlets of the three air ducts; The three air ducts are installed side by side and extended to the outlet end of the air duct and fixed side by side.

[0025] The three air ducts have the same structure, but heaters with different powers are used. Heater 1, heater 2, and heater 3 are respectively composed of several resistive heating elements fixed on the substrate of the heater device; the heater adopts resistive heating The way;

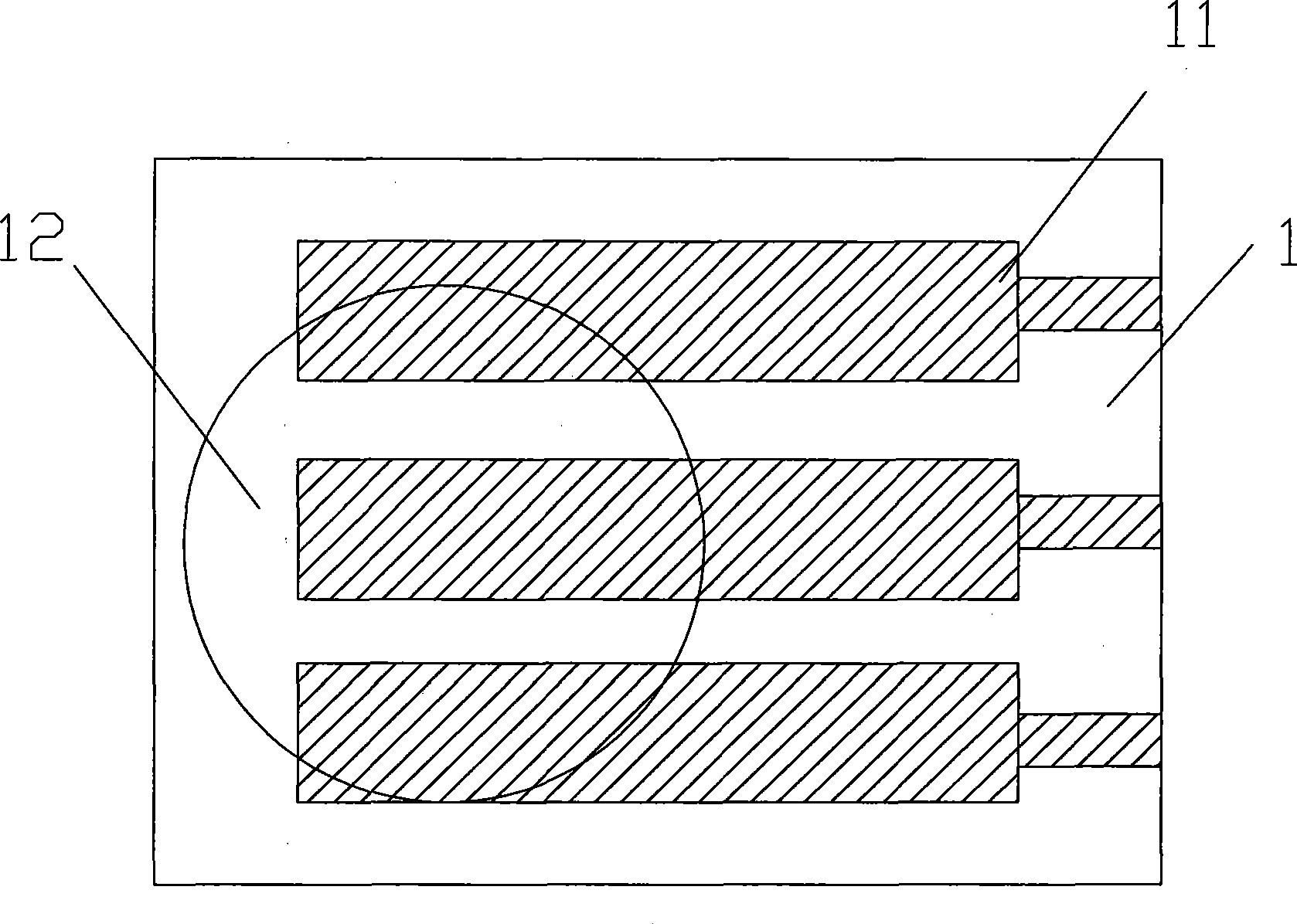

[0026] Taking one of the above three air ducts as an example, the structural diagram of the heater 1 is as follows: figure 2 As shown; the heater 1 includes three resistive heating elements 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com