Compound fertilizer mixing system based on lever principle

A technology of mixing system and lever principle, which is applied in mixers, mixers, chemical/physical processes and other directions with rotating stirring devices, can solve the problems of inconvenient mixing ratio and difficult to mix evenly, achieve simple and convenient adjustment process and improve mixing. Efficient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

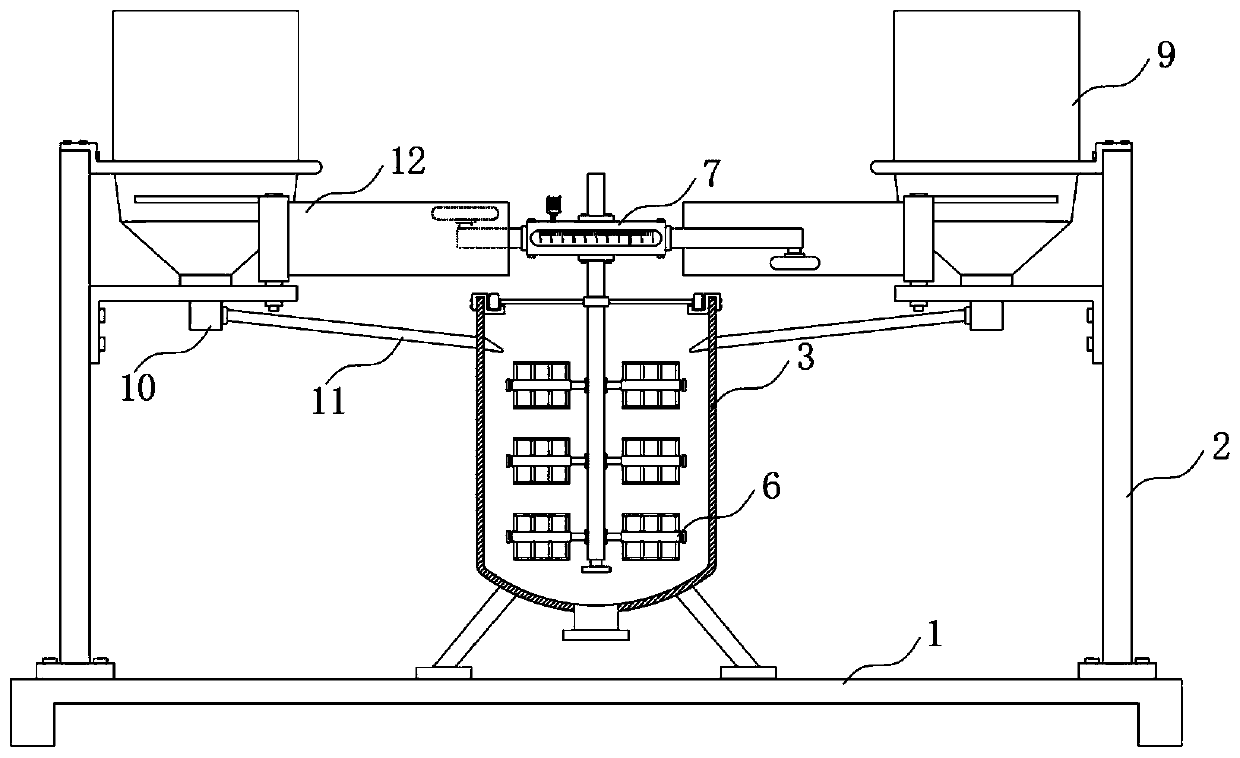

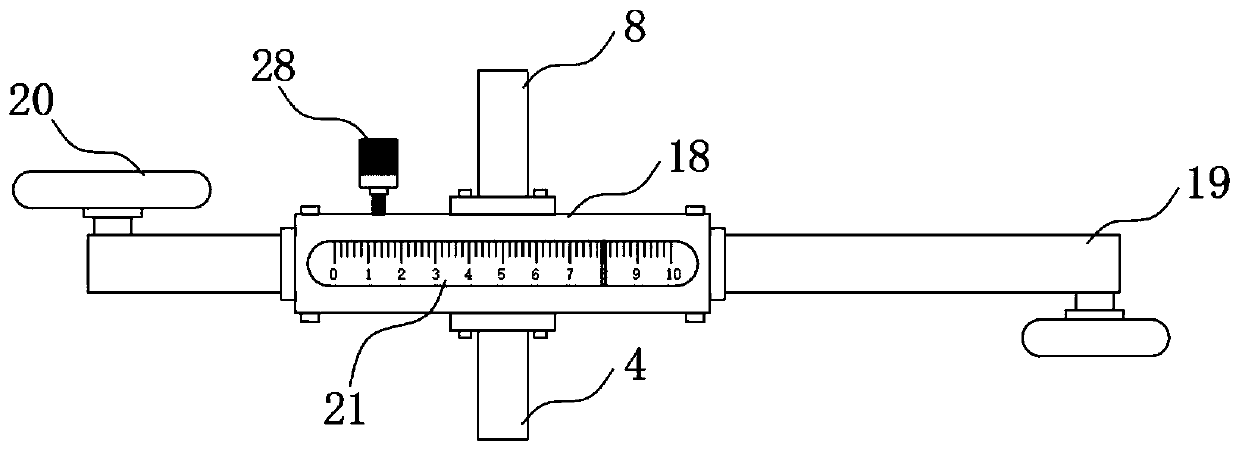

[0027] Such as Figure 1-5 As shown, a compound fertilizer mixing system based on the principle of leverage includes a base 1, a support 2 is fixedly connected to both sides of the base 1, a mixing tank 3 is fixedly connected between the two supports 2, and the two supports 2 are respectively set On the front and rear sides of the mixing tank 3, a vertically arranged stirring shaft 4 is arranged inside the mixing tank 3, and a reinforcing mechanism 5 for reinforcing the stirring shaft 4 is arranged inside the mixing tank 3.

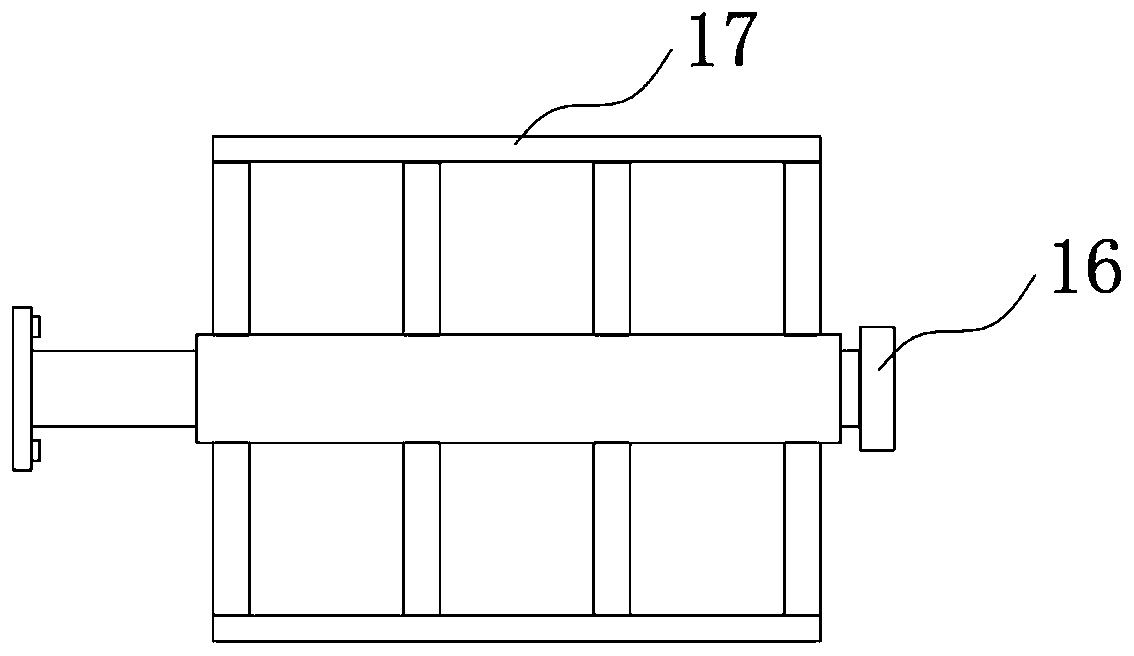

[0028] Further, the reinforcement mechanism 5 is composed of a reinforcement ring 13, a plurality of connecting rods 14 and a plurality of rollers 15, one end of the plurality of connecting rods 14 is fixedly connected to the stirring shaft 4, and the other end is rotatably connected to the roller 15, and the axis of the roller 15 Coincident with the axis of the connecting rod 14, the roller 15 is rolled in the annular rolling groove of the reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com