A Processing Method for Controlling Angled Dustproof Groove

A processing method and a technology of dust-proof grooves, which are applied in the field of processing to control angled dust-proof grooves, can solve the problems of high inspection cost and low pass rate of processing methods, and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

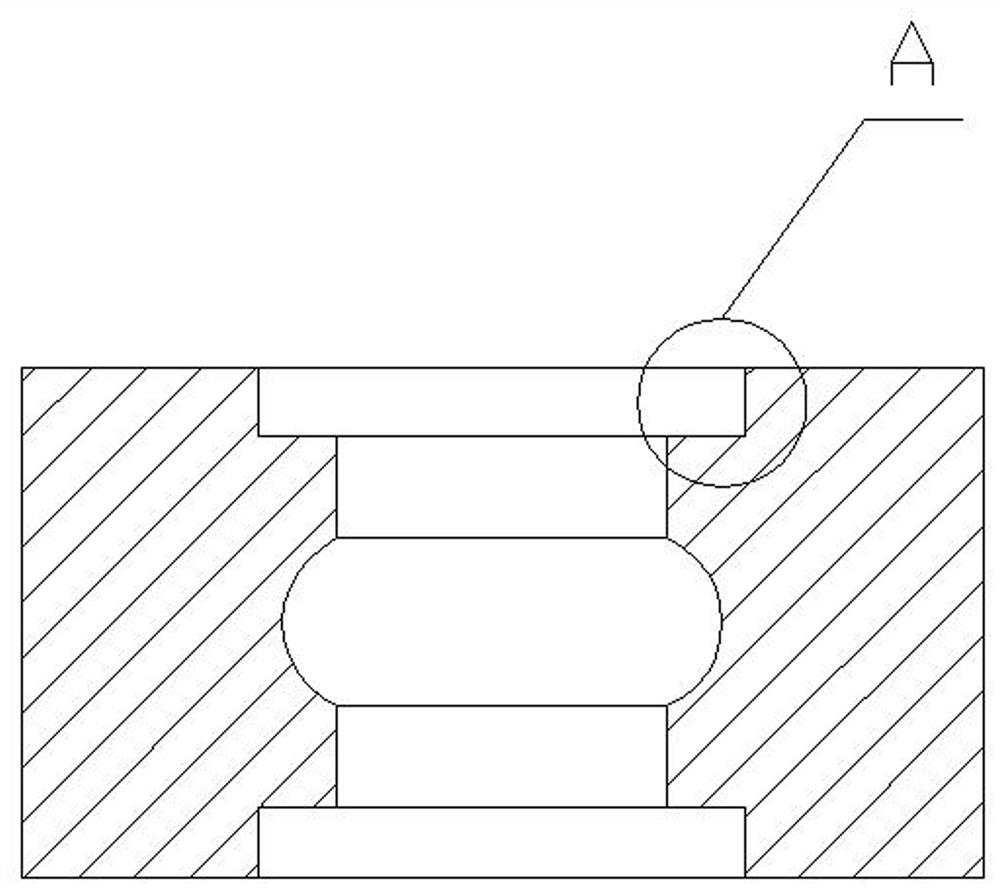

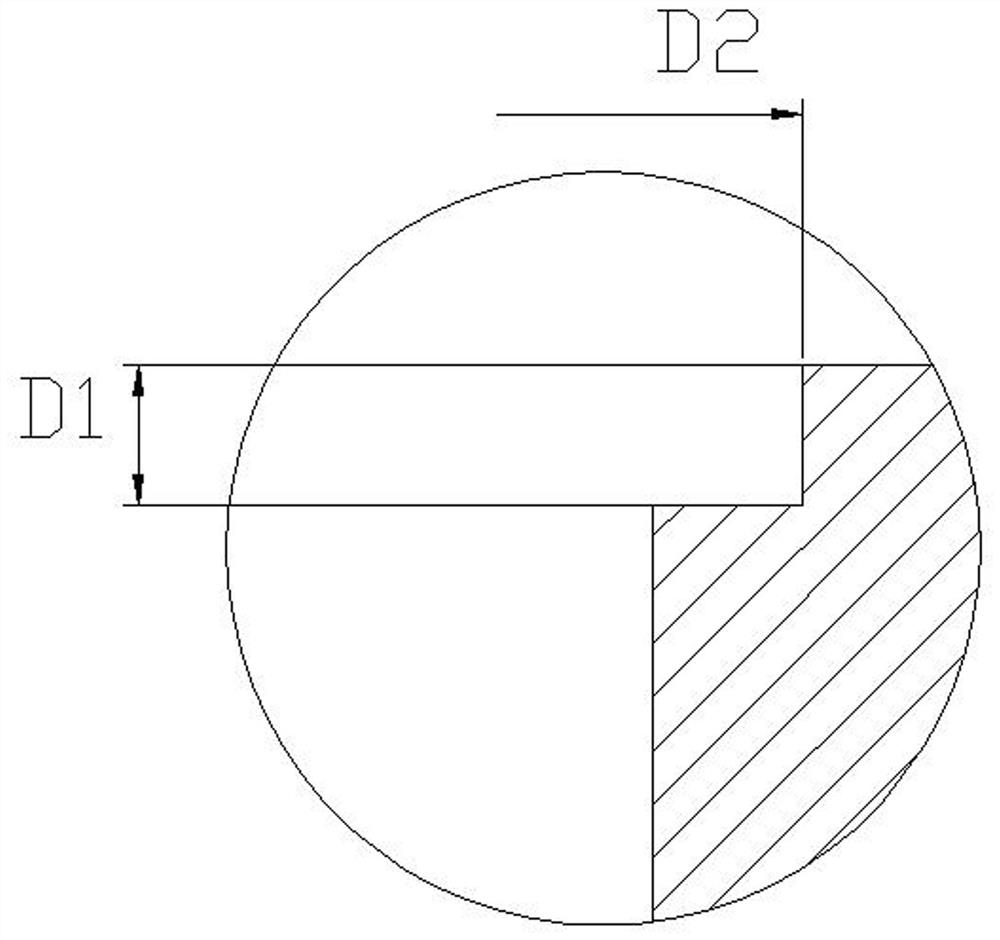

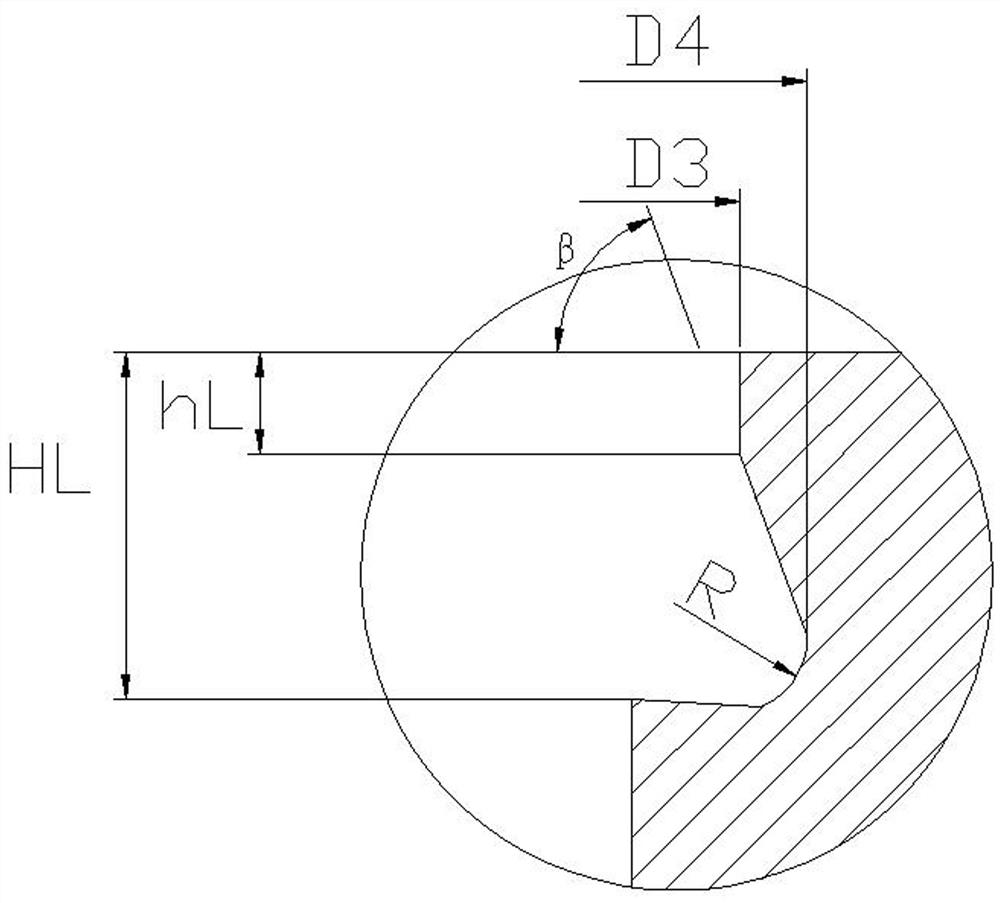

[0024] A processing method for controlling the angled dust-proof groove of the present invention is used for such as figure 1 The processing of the dust-proof grooves on both end faces of the bearing shown, after processing, as shown in image 3 shown. The present invention is based on the GS150PLUS machine tool. First, the bottom end face of the dust-proof groove is processed through the turning tool 1 of the machine tool, and then the curvature radius R of the bottom groove of the dust-proof groove and the angle β of the dust-proof cover groove are processed, and finally the edge of the dust-proof cover is processed. Width hL, that is, to accurately complete the processing of the dust-proof groove.

[0025] Specifically, such as Figure 5 Shown, the present invention comprises the following steps:

[0026] 1) Process the bottom surface of the dust-proof groove

[0027] After tool setting of turning tool 1, make turning tool 1 move downward along the axial direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com