Specially-shaped clamping piece flap wheel

A thousand-page wheel and clip technology, which is applied to the wheels, abrasives, metal processing equipment and other directions of the working part with flexibility, can solve the problems that affect the use efficiency of the thousand-page wheel, the heat cannot be dissipated quickly, and the grinding cannot be performed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

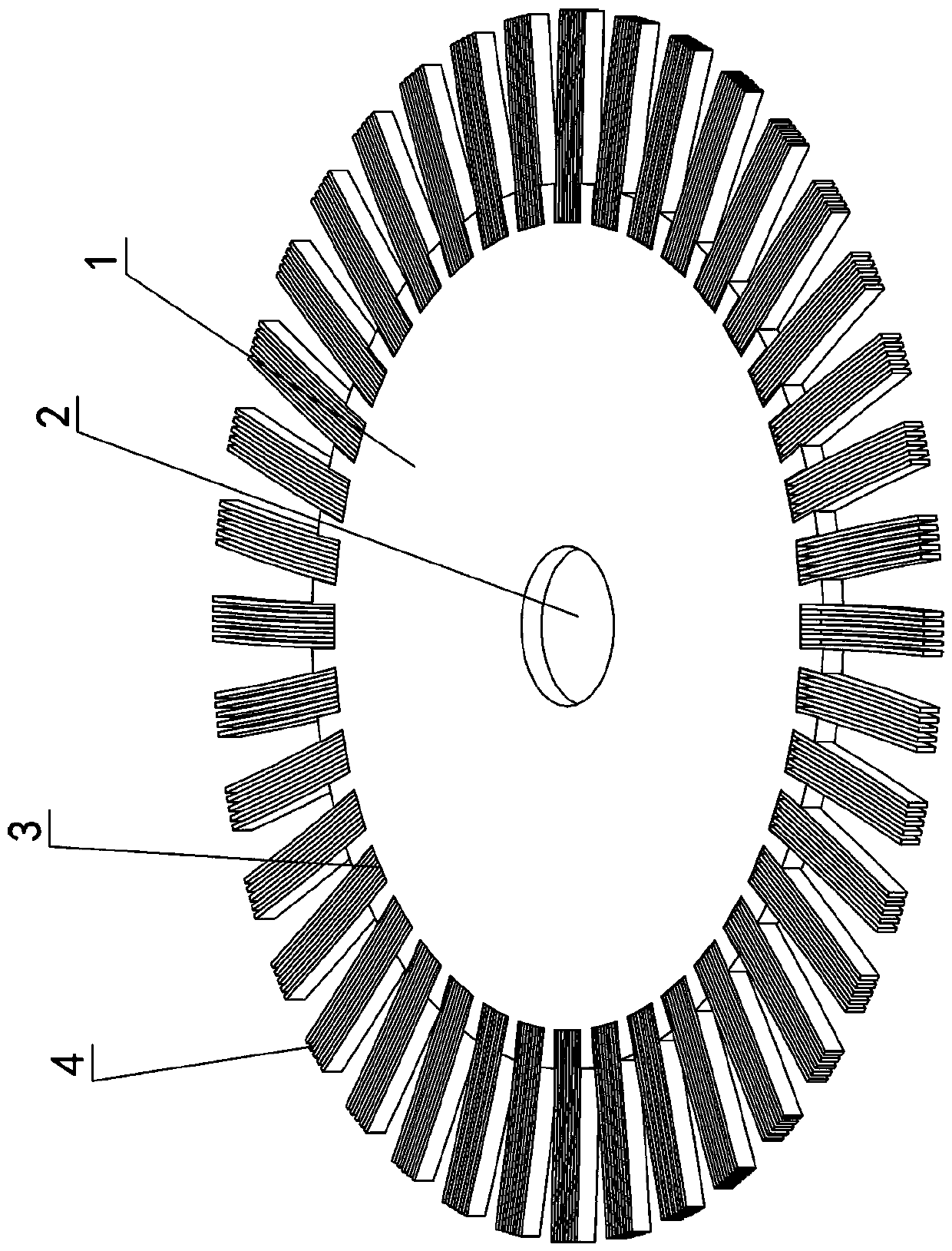

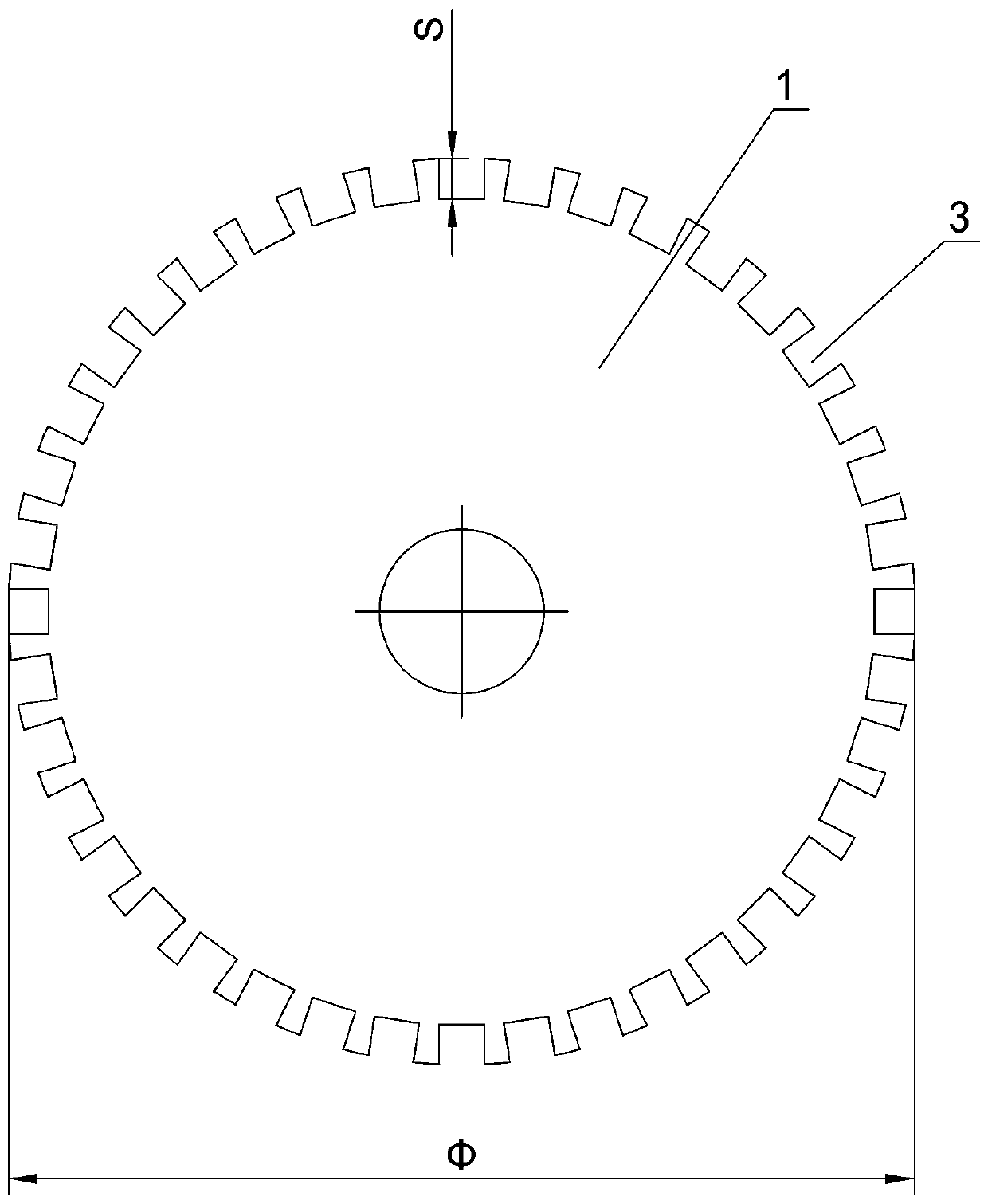

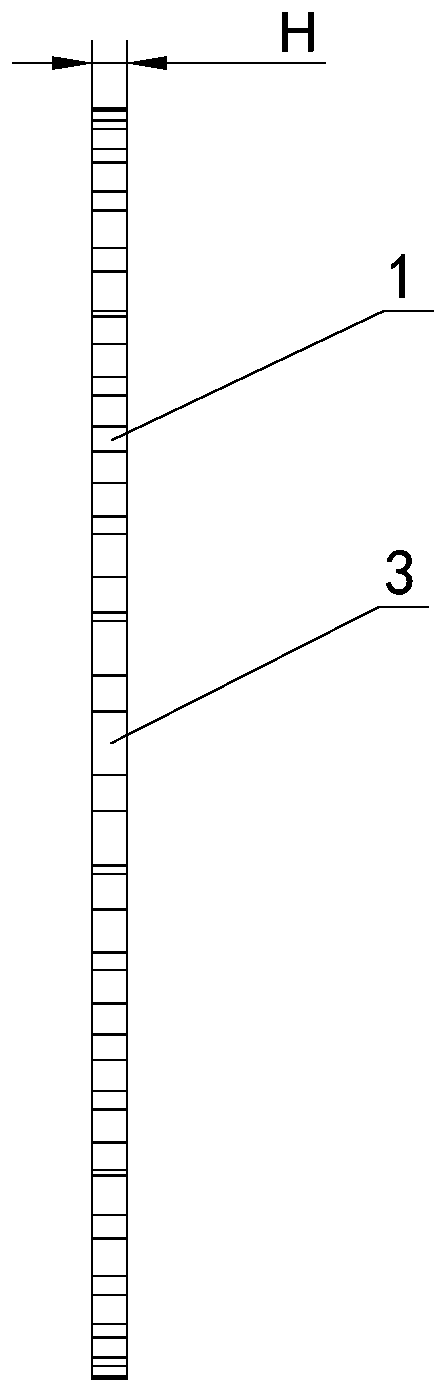

[0010] The invention relates to a thousand-page wheel with special-shaped clips, such as figure 1 — image 3 As shown, it includes a circular base body 1, and the center of the circular base body is provided with a shaft hole 2, and the circumference of the circular base body 1 is provided with evenly spaced tooth openings 3, and each tooth opening 3 is embedded with an emery cloth clip 4 . The main feature of this program is that the evenly spaced tooth openings 3 are arranged on the periphery of the circular substrate 1, and each tooth opening 3 is embedded with an abrasive cloth clip 4, and the abrasive cloth clips 4 are stacked one by one. During processing, the emery cloth is first punched and divided into strips, made into strips, semicircular or tapered shapes, and then the emery cloth is stacked one by one to form the emery cloth clip 4. The size of the emery cloth clip 4 is the same as the tooth mouth 3, then insert the abrasive cloth clip 4 into the tooth opening 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com