Pressing device for producing external wall insulation board

A technology of external wall insulation board and pressing device, which is applied in the field of external wall insulation board, and can solve the problems that the insulation board slurry cannot be uniformly arranged inside the insulation board, and the external wall insulation board cannot be pressed and processed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

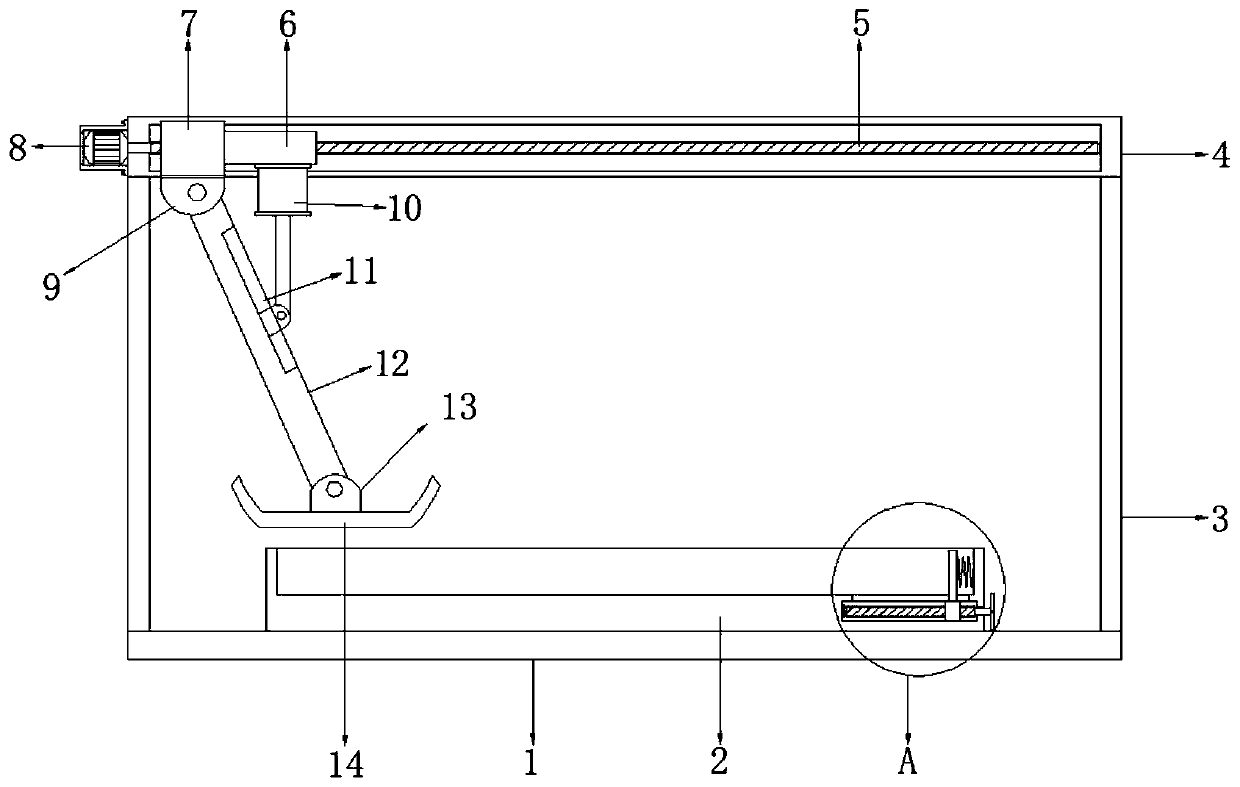

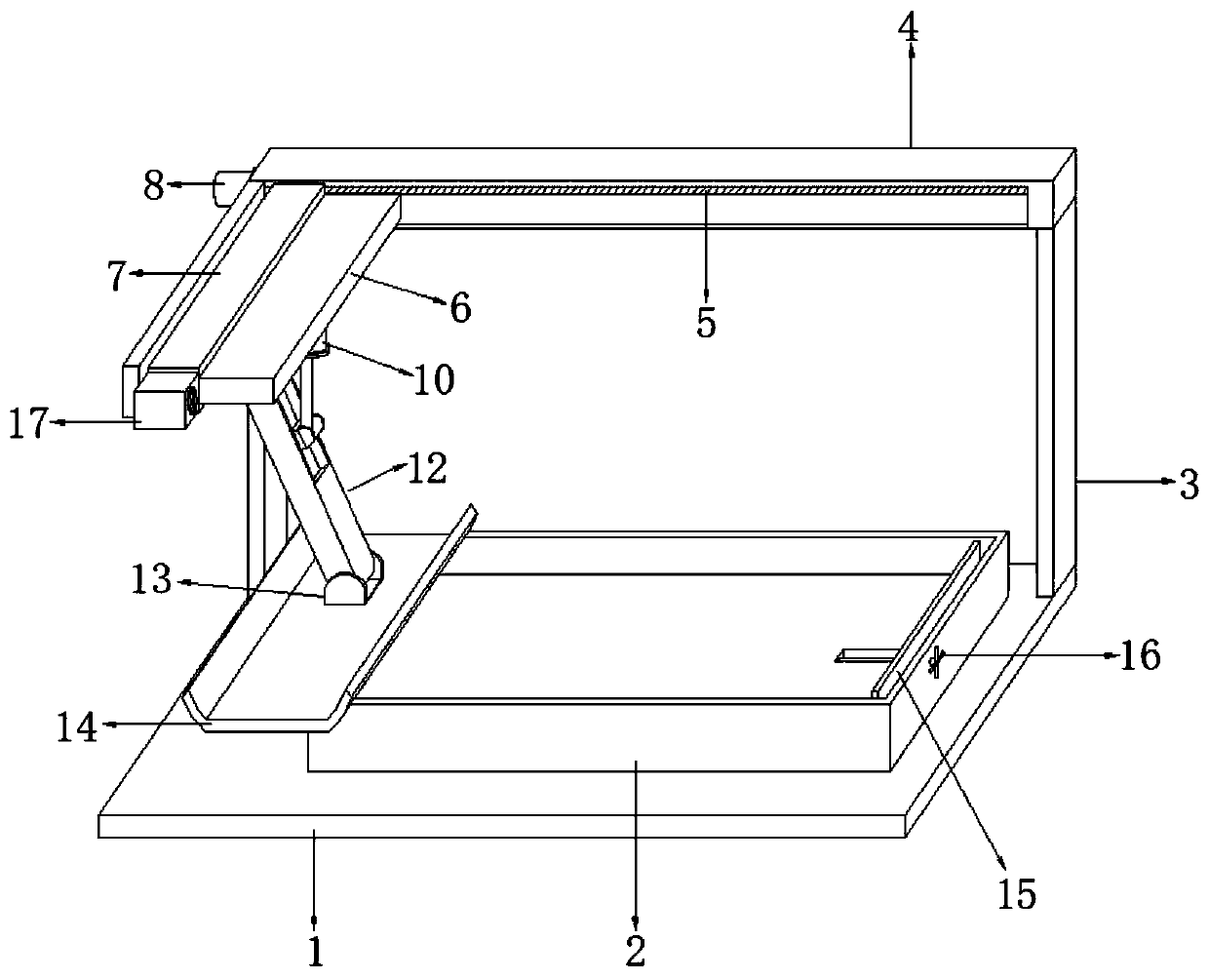

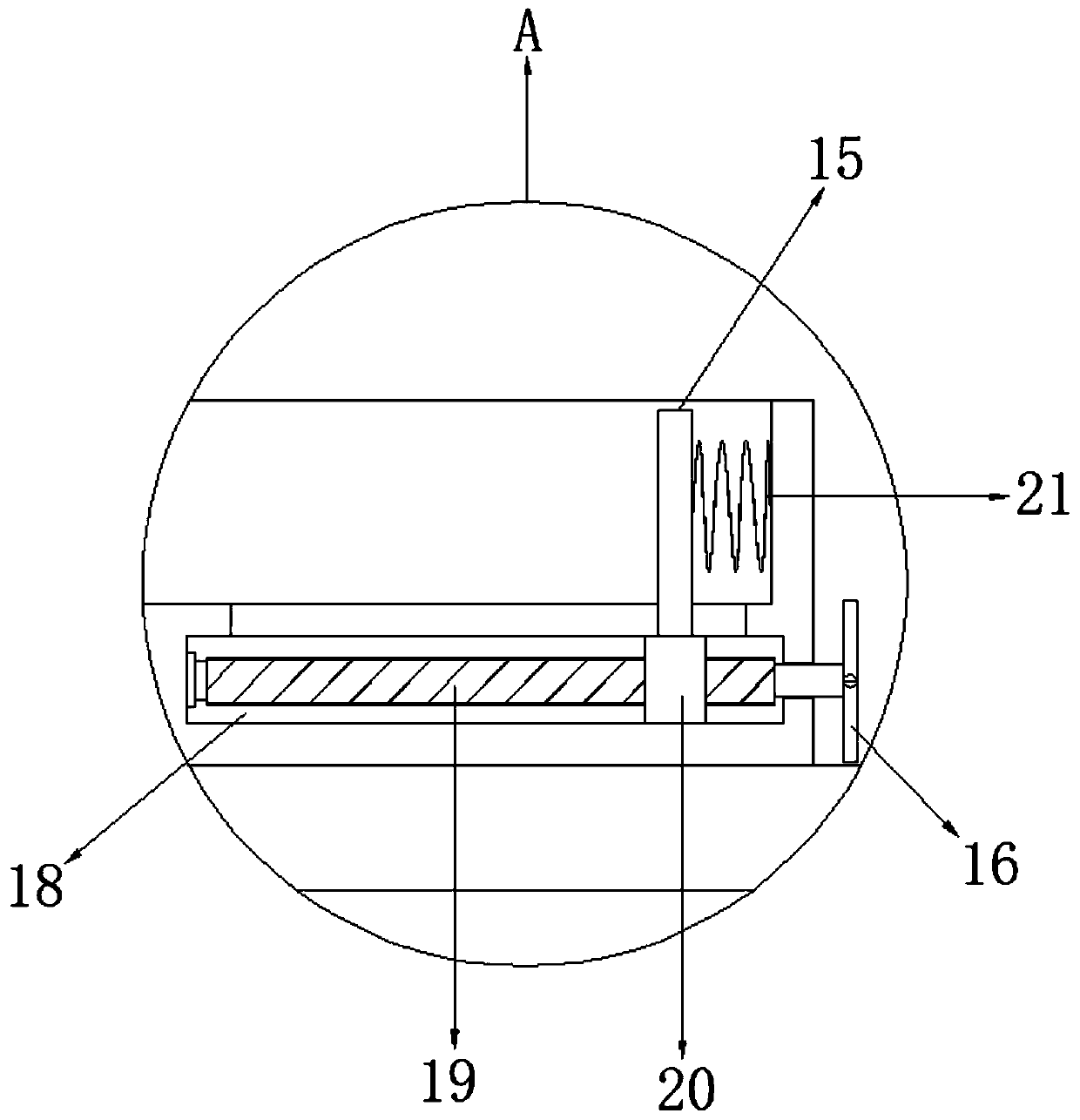

[0029] refer to Figure 1-3 , a pressing device for the production of external wall insulation boards, including a support base plate 1, support columns 3 are welded to the top four corners of the support base plate 1, and top frames 4 are connected to the tops of two adjacent support columns 3 by bolts. One end of the outer wall on the opposite side of the frame 4 is connected with a connecting rod through a bolt, and the outer walls at one end of the two top frames 4 are connected with a forward and reverse motor 8 through a bolt, and the output shaft of the forward and reverse motor 8 extends into the top frame One end in 4 is all connected with threaded lead screw 5 by bolt, and the outer wall of threaded lead screw 5 is all screwed and connected with movable sleeve 17 that coincides with the inner wall of top frame 4, and the opposite side outer wall of movable sleeve 17 is welded with mounting plate 7 , and the middle position of the bottom of the mounting plate 7 is con...

Embodiment 2

[0039] refer to Figure 4 , a pressing device for the production of external wall insulation boards. Compared with Embodiment 1, the outer walls of both sides of the movable rod 12 in this embodiment are welded with fixed plates 22, and the bottom of the fixed plate 22 and the top of the pressing part 14 A second electric push rod 23 is rotatably connected between both sides.

[0040] Working principle: when the pressing part 14 is attached to the top surface of the insulation board, the second electric push rod 23 is used to limit the two ends of the pressing part 14 to prevent the pressing part 14 from being unstable.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap