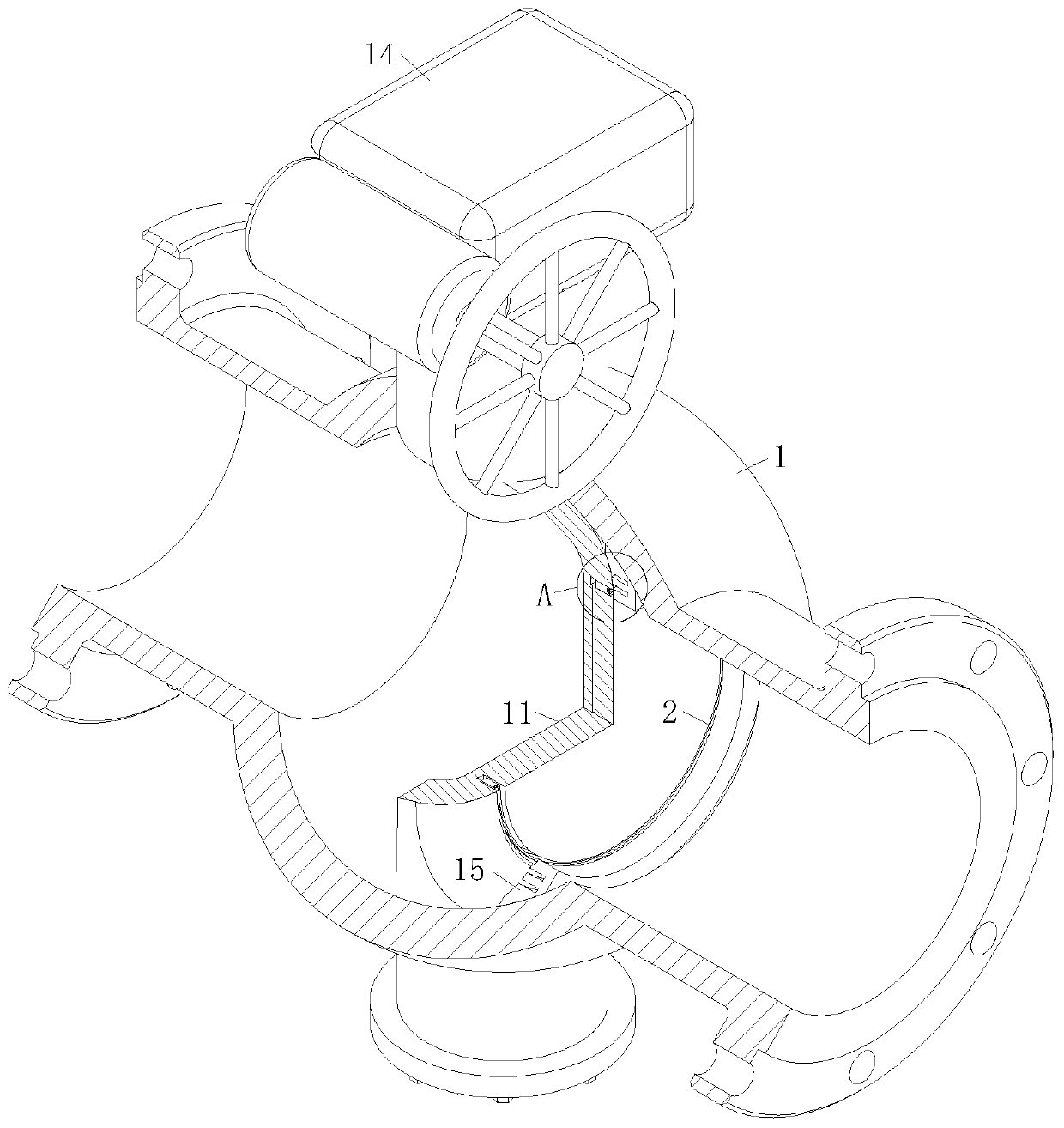

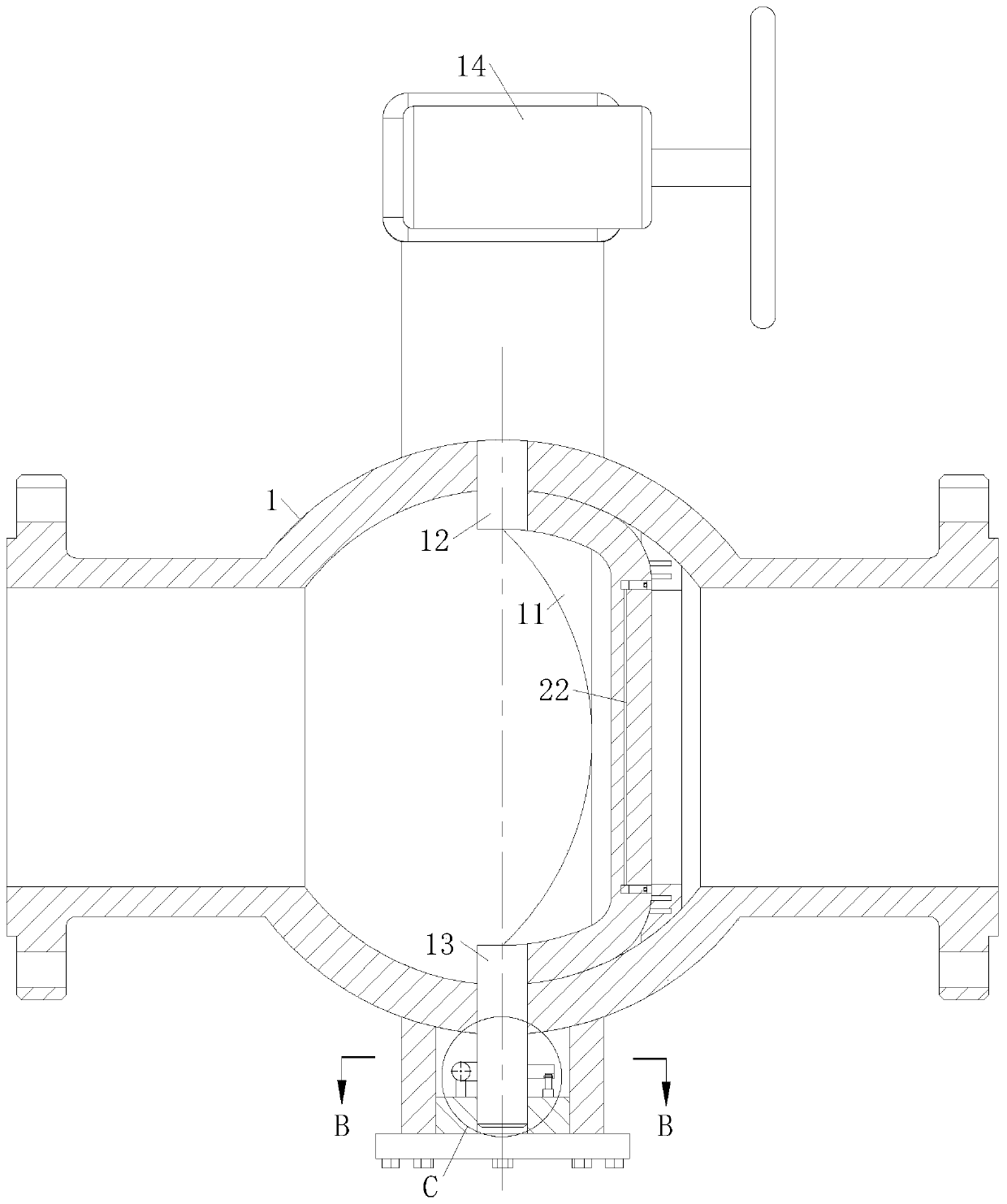

Eccentric butterfly valve

An eccentric butterfly valve technology, applied in the direction of lifting valves, valve devices, engine components, etc., can solve problems affecting the sealing performance of butterfly valves, internal leakage of butterfly valves, etc., and achieve the effect of reducing internal leakage, reducing resistance, and increasing active sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

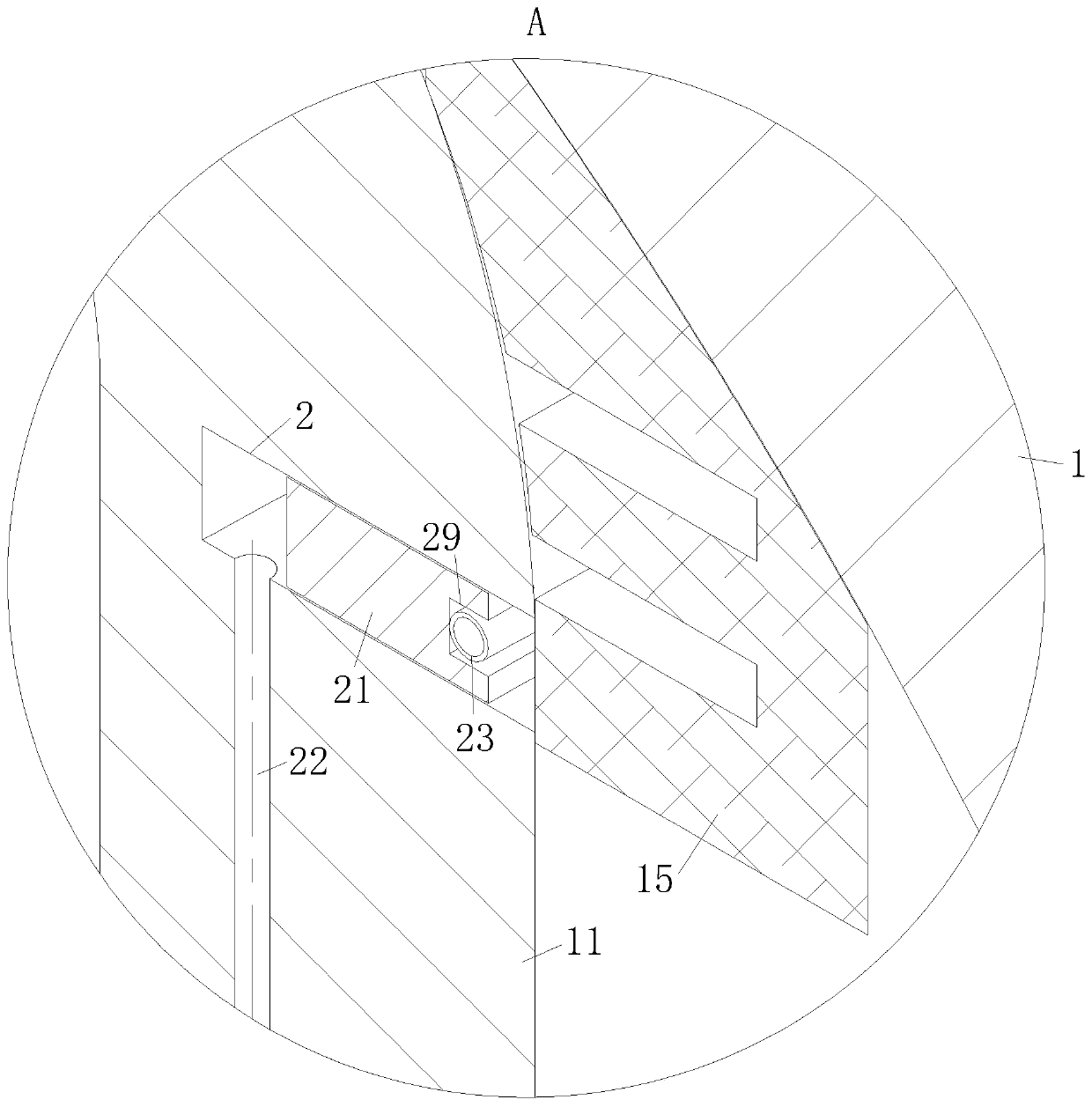

[0025] As an embodiment of the present invention, an annular groove 29 is provided on the end surface of the sealing cylinder 21 close to the valve seat 15, and an annular hollow bag 23 is embedded in the annular groove 29, and the hollow bag 23 is filled with liquid; 23 Squeeze the deformation of the valve seat 15, increase the tightness of the sealing cylinder 21 and the valve seat 15, and further reduce the internal leakage of the butterfly valve; after the hollow bag 23 is elastically deformed by the extrusion force between the annular groove 29 and the valve seat 15, the hollow space is increased. The fitting degree between the bladder 23 and the valve seat 15 makes the valve seat 15 slightly scratched or surface corroded, and the hollow bladder 23 can closely fit the valve seat 15, thereby reducing the leakage between the valve plate 11 and the valve seat 15, ensuring The sealing effect of the butterfly valve is to increase the supporting force of the hollow capsule 23 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com