Polishing and water spraying device for rice processing

A water spray device and rice processing technology, applied in application, grain finishing, grain processing, etc., can solve the problems of poor rice polishing effect and uneven polishing of rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

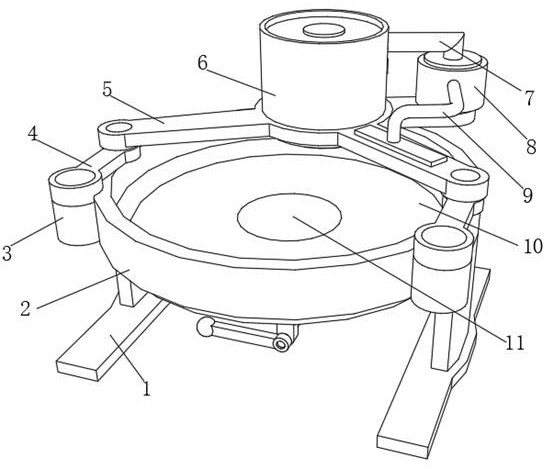

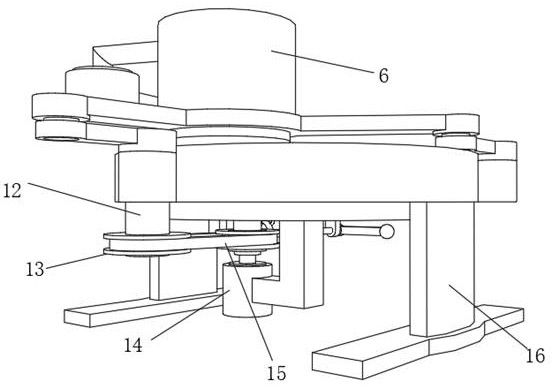

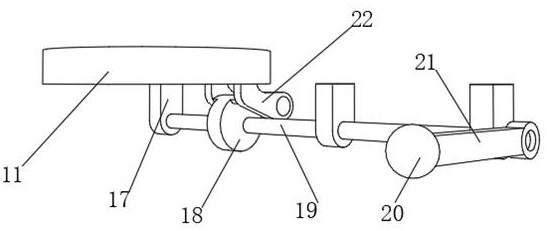

[0032] A polishing water spray device for rice processing, such as Figure 1-5As shown, the main body cylinder 2 is included, and the outer walls on both sides of the bottom of the main body cylinder 2 are fixed with support plates 16 by bolts, and the bottom outer walls of the two support plates 16 are fixed with a bottom plate 1 by bolts, and the bottom of the main body cylinder 2 The inner wall is provided with a trough 10, the center of the bottom of the main cylinder 2 is provided with a discharge opening 26, the main cylinder 2 is provided with a material guide mechanism near the bottom of the discharge opening 26, and the outer wall of the main cylinder 2 is provided with three installation grooves, and each The inwall of each mounting groove is all welded with mount 3, and the top outer wall of each mount 3 has guide hole 25, and the top outer wall of each guide hole 25 is all fixed with guide rod 4 by rotating shaft, and each guide rod 4. One end is fixed with the sam...

Embodiment 2

[0037] A polishing water spray device for rice processing, such as Figure 4 Shown, in order to improve the efficiency and the quality of rice polishing; The present embodiment makes the following improvements on the basis of Embodiment 1: the inner wall of the circumference outer ring of the storage tank 10 is bonded with a bevel ring 24, and the storage tank 10 The inner wall of the bottom circumference is bonded with arc-shaped rubber strips 23 distributed equidistantly; the setting of the slope ring 24 effectively avoids the problem that the rice is broken when it hits the peripheral corner of the storage tank 10, and improves the integrity of the rice. At the same time, the arc-shaped rubber strip 23 effectively promotes the friction effect between the rice and the friction arc surface protrusion 27, and improves the efficiency and quality of rice polishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com