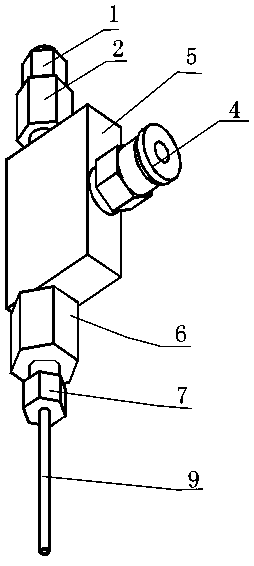

High-precision automatic viscometer sample inlet unit and viscometer automatic sample injector

A viscometer and sampling port technology, which is applied in the field of liquid sampling equipment, can solve problems such as low precision, influence on use effect, and increase in instrument cost, and achieve the effect of improving the precision of sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

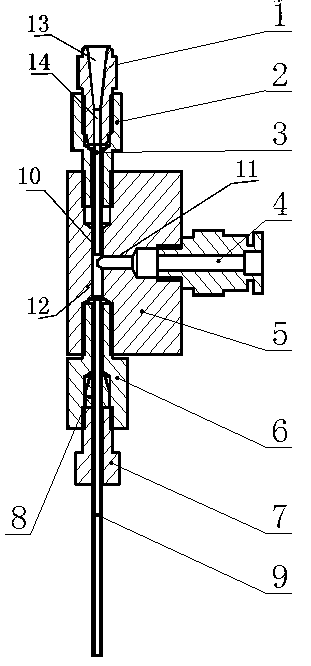

Examples

Embodiment 2

[0029] Sealing Example 2 differs from Example 1 in that the other end of the solvent pipe 3 is also provided with an extension ear along the circumference, and the extension ear is also perpendicular to the solvent pipe 3 axis, and the extension ear provided at one end of the solvent pipe 3 passes through the The cylinder body 1 presses the extension ear so that the upper end of the solvent pipe 3 is sealed with the first screw 2, and the extension ear provided at the other end of the solvent pipe 3 presses the extension ear through the first screw 2 to make the lower end of the solvent pipe 3 contact the first interface 10 Sealed settings. Under the condition that the length of the solvent tube is the same as the length of the through hole of the first screw, by setting an extension ear at the other end of the solvent tube 3, it is possible to ensure that the sample discharged from the injection needle can flow into the injection port of the instrument. , to prevent the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com